Product Description

Spline Round Key Way Pin Threaded CZPT Hollow Through Hole Flat D Shape Knurling Spur Helical Worm Transmission Drive Auto Parts Gear Pinion Gearbox Axis Shaft

Features

1. High precision gear shaft for smooth, quiet operation.

2. Flexible for custom-made requests.

3. Stable transmission, low impact, vibration, and noise.

4. Heavy Load capability, more compact, but less complex.

Product Description

| Products | Spur Gear, Helical Gear, Herringbone Gear, Spiral Bevel Gear, Straight Bevel Gear, Worm Gear, Shaft, Pinion |

| Module | M0.3-M10 |

| Precision grade | DIN6, DIN7, DIN8, DIN10 |

| Pressure angle | 14.5 degree, 15 degree, 20 degree |

| Material | Medium Carbon Steel: 35#, 45# Carburizing Steel: 20CrMnTi, 20CrMnMo, 20CrMo Alloy Steel: 40Cr, 35CrMo, 42CrMo, 40CrNiMo Cast Iron: HT250, QT400 Copper, Stainless Steel, Brass, Nylon, POM, and so on |

| Heat treatment | Hardening & Tempering, Surface Quenching, Integral Quenching, Carburizing Quenching, Tempering, Normalizing, Nitriding |

| Surface treatment | Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

| Application | Gearbox and reducer; Precision cutting machines, Lathes machines; Milling machines; Grinder machine; Automated mechanical systems; Automated warehousing systems. Gear hobbing machines, gear shapers, gear shaving machines, gear milling, gear grinding machines and many kinds of gear-related machines. |

| Machining process | Forging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment… |

Detailed Photos

Our Advantages

Related Product

Company Profile

FAQ

Q: How to ship the worm gear to us?

A: It is available by air, sea, or train.

Q: How to pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Gearbox |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample Worm gear with shaft

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

How do drive shafts handle variations in load and vibration during operation?

Drive shafts are designed to handle variations in load and vibration during operation by employing various mechanisms and features. These mechanisms help ensure smooth power transmission, minimize vibrations, and maintain the structural integrity of the drive shaft. Here’s a detailed explanation of how drive shafts handle load and vibration variations:

1. Material Selection and Design:

Drive shafts are typically made from materials with high strength and stiffness, such as steel alloys or composite materials. The material selection and design take into account the anticipated loads and operating conditions of the application. By using appropriate materials and optimizing the design, drive shafts can withstand the expected variations in load without experiencing excessive deflection or deformation.

2. Torque Capacity:

Drive shafts are designed with a specific torque capacity that corresponds to the expected loads. The torque capacity takes into account factors such as the power output of the driving source and the torque requirements of the driven components. By selecting a drive shaft with sufficient torque capacity, variations in load can be accommodated without exceeding the drive shaft’s limits and risking failure or damage.

3. Dynamic Balancing:

During the manufacturing process, drive shafts can undergo dynamic balancing. Imbalances in the drive shaft can result in vibrations during operation. Through the balancing process, weights are strategically added or removed to ensure that the drive shaft spins evenly and minimizes vibrations. Dynamic balancing helps to mitigate the effects of load variations and reduces the potential for excessive vibrations in the drive shaft.

4. Dampers and Vibration Control:

Drive shafts can incorporate dampers or vibration control mechanisms to further minimize vibrations. These devices are typically designed to absorb or dissipate vibrations that may arise from load variations or other factors. Dampers can be in the form of torsional dampers, rubber isolators, or other vibration-absorbing elements strategically placed along the drive shaft. By managing and attenuating vibrations, drive shafts ensure smooth operation and enhance overall system performance.

5. CV Joints:

Constant Velocity (CV) joints are often used in drive shafts to accommodate variations in operating angles and to maintain a constant speed. CV joints allow the drive shaft to transmit power even when the driving and driven components are at different angles. By accommodating variations in operating angles, CV joints help minimize the impact of load variations and reduce potential vibrations that may arise from changes in the driveline geometry.

6. Lubrication and Maintenance:

Proper lubrication and regular maintenance are essential for drive shafts to handle load and vibration variations effectively. Lubrication helps reduce friction between moving parts, minimizing wear and heat generation. Regular maintenance, including inspection and lubrication of joints, ensures that the drive shaft remains in optimal condition, reducing the risk of failure or performance degradation due to load variations.

7. Structural Rigidity:

Drive shafts are designed to have sufficient structural rigidity to resist bending and torsional forces. This rigidity helps maintain the integrity of the drive shaft when subjected to load variations. By minimizing deflection and maintaining structural integrity, the drive shaft can effectively transmit power and handle variations in load without compromising performance or introducing excessive vibrations.

8. Control Systems and Feedback:

In some applications, drive shafts may be equipped with control systems that actively monitor and adjust parameters such as torque, speed, and vibration. These control systems use sensors and feedback mechanisms to detect variations in load or vibrations and make real-time adjustments to optimize performance. By actively managing load variations and vibrations, drive shafts can adapt to changing operating conditions and maintain smooth operation.

In summary, drive shafts handle variations in load and vibration during operation through careful material selection and design, torque capacity considerations, dynamic balancing, integration of dampers and vibration control mechanisms, utilization of CV joints, proper lubrication and maintenance, structural rigidity, and, in some cases, control systems and feedback mechanisms. By incorporating these features and mechanisms, drive shafts ensure reliable and efficient power transmission while minimizing the impact of load variations and vibrations on overall system performance.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2023-12-13

China Best Sales Kaf107 Helical Bevel Transmission Gearbox Right Angle Shaft with 7.5kw Motor for Tower Cranes with Hot selling

Merchandise Description

SC Transmission helical-bevel geared motor KAF107

helical-bevel geared motor KAF sequence

product:KAF37,KAF47,KAF57,KAF67…..KAF157

one:KAF B5 flange mounted with hollow shaft

two:KVF B5 flange mounted with splined hollow shaft

three:KHF B5 flange mounted with foot mounted and hollow shaft and shrink disk

Features:

- Higher effectiveness: 92%-93%

- Vertical output, compact composition, difficult tooth surface , big output torque, low noise and long service life.

- Higher precision: the equipment is created of substantial-quality alloy metal forging, carbonitriding and hardening treatment, grinding approach to guarantee higher precision and steady operating.

- Large interchangeability: highly modular, serial style, robust flexibility and interchangeability.

cyc lo equipment box box

| Ratio | 5.36-197.37 |

| Input power | 0.12-200KW |

| Output torque | 10–62800N.m |

| Output speed | 7-415rpm |

| Mounting type | Foot mounted, foot mounted with solid shaft, output flange mounted, hollow shaft mounted, B5 flange mounted with hollow shaft, foot mounted with hollow shaft, B14 flange mounted with hollow shaft, foot mounted with splined hole, foot mounted with shrink disk, hollow shaft mounted with anti-torque arm. |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

| Brake Release | HF-manual release(lock in the brake release position), HR-manual release(autom-atic braking position) |

| Thermistor | TF(Thermistor protection PTC thermisto) TH(Thermistor protection Bimetal swotch) |

| Mounting Position | M1, M2, M3, M4, M5, M6 |

| Type | K37-K157 |

| Output shaft dis. | 25mm, 30mm, 35mm, 40mm, 50mm, 60mm, 70mm, 90mm, 110mm, 120mm |

| Housing material | HT200 high-strength cast iron from R37,47,57,67,77,87 |

| Housing material | HT250 High strength cast iron from R97 107,137,147, 157,167,187 |

| Heat treatment technology | carbonitriding and hardening treatment |

| Single Stage Efficiency | up to 96% |

| Lubricant | VG220 |

| Protection Class | IP55, F class |

| Ratio | 5.36-197.37 |

| Input power | 0.12-200KW |

| Output torque | 10–62800N.m |

| Output speed | 7-415rpm |

| Mounting type | Foot mounted, foot mounted with solid shaft, output flange mounted, hollow shaft mounted, B5 flange mounted with hollow shaft, foot mounted with hollow shaft, B14 flange mounted with hollow shaft, foot mounted with splined hole, foot mounted with shrink disk, hollow shaft mounted with anti-torque arm. |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

| Brake Release | HF-manual release(lock in the brake release position), HR-manual release(autom-atic braking position) |

| Thermistor | TF(Thermistor protection PTC thermisto) TH(Thermistor protection Bimetal swotch) |

| Mounting Position | M1, M2, M3, M4, M5, M6 |

| Type | K37-K157 |

| Output shaft dis. | 25mm, 30mm, 35mm, 40mm, 50mm, 60mm, 70mm, 90mm, 110mm, 120mm |

| Housing material | HT200 high-strength cast iron from R37,47,57,67,77,87 |

| Housing material | HT250 High strength cast iron from R97 107,137,147, 157,167,187 |

| Heat treatment technology | carbonitriding and hardening treatment |

| Single Stage Efficiency | up to 96% |

| Lubricant | VG220 |

| Protection Class | IP55, F class |

Drive shaft type

The driveshaft transfers torque from the engine to the wheels and is responsible for the smooth running of the vehicle. Its design had to compensate for differences in length and angle. It must also ensure perfect synchronization between its joints. The drive shaft should be made of high-grade materials to achieve the best balance of stiffness and elasticity. There are three main types of drive shafts. These include: end yokes, tube yokes and tapered shafts.

tube yoke

Tube yokes are shaft assemblies that use metallic materials as the main structural component. The yoke includes a uniform, substantially uniform wall thickness, a first end and an axially extending second end. The first diameter of the drive shaft is greater than the second diameter, and the yoke further includes a pair of opposing lugs extending from the second end. These lugs have holes at the ends for attaching the axle to the vehicle.

By retrofitting the driveshaft tube end into a tube fork with seat. This valve seat transmits torque to the driveshaft tube. The fillet weld 28 enhances the torque transfer capability of the tube yoke. The yoke is usually made of aluminum alloy or metal material. It is also used to connect the drive shaft to the yoke. Various designs are possible.

The QU40866 tube yoke is used with an external snap ring type universal joint. It has a cup diameter of 1-3/16″ and an overall width of 4½”. U-bolt kits are another option. It has threaded legs and locks to help secure the yoke to the drive shaft. Some performance cars and off-road vehicles use U-bolts. Yokes must be machined to accept U-bolts, and U-bolt kits are often the preferred accessory.

The end yoke is the mechanical part that connects the drive shaft to the stub shaft. These yokes are usually designed for specific drivetrain components and can be customized to your needs. Pat’s drivetrain offers OEM replacement and custom flanged yokes.

If your tractor uses PTO components, the cross and bearing kit is the perfect tool to make the connection. Additionally, cross and bearing kits help you match the correct yoke to the shaft. When choosing a yoke, be sure to measure the outside diameter of the U-joint cap and the inside diameter of the yoke ears. After taking the measurements, consult the cross and bearing identification drawings to make sure they match.

While tube yokes are usually easy to replace, the best results come from a qualified machine shop. Dedicated driveshaft specialists can assemble and balance finished driveshafts. If you are unsure of a particular aspect, please refer to the TM3000 Driveshaft and Cardan Joint Service Manual for more information. You can also consult an excerpt from the TSB3510 manual for information on angle, vibration and runout.

The sliding fork is another important part of the drive shaft. It can bend over rough terrain, allowing the U-joint to keep spinning in tougher conditions. If the slip yoke fails, you will not be able to drive and will clang. You need to replace it as soon as possible to avoid any dangerous driving conditions. So if you notice any dings, be sure to check the yoke.

If you detect any vibrations, the drivetrain may need adjustment. It’s a simple process. First, rotate the driveshaft until you find the correct alignment between the tube yoke and the sliding yoke of the rear differential. If there is no noticeable vibration, you can wait for a while to resolve the problem. Keep in mind that it may be convenient to postpone repairs temporarily, but it may cause bigger problems later.

end yoke

If your driveshaft requires a new end yoke, CZPT has several drivetrain options. Our automotive end yoke inventory includes keyed and non-keyed options. If you need tapered or straight holes, we can also make them for you.

A U-bolt is an industrial fastener that has U-shaped threads on its legs. They are often used to join two heads back to back. These are convenient options to help keep drivetrain components in place when driving over rough terrain, and are generally compatible with a variety of models. U-bolts require a specially machined yoke to accept them, so be sure to order the correct size.

The sliding fork helps transfer power from the transfer case to the driveshaft. They slide in and out of the transfer case, allowing the u-joint to rotate. Sliding yokes or “slips” can be purchased separately. Whether you need a new one or just a few components to upgrade your driveshaft, 4 CZPT Parts will have the parts you need to repair your vehicle.

The end yoke is a necessary part of the drive shaft. It connects the drive train and the mating flange. They are also used in auxiliary power equipment. CZPT’s drivetrains are stocked with a variety of flanged yokes for OEM applications and custom builds. You can also find flanged yokes for constant velocity joints in our extensive inventory. If you don’t want to modify your existing drivetrain, we can even make a custom yoke for you.

China manufacturer & factory supplier for china in Kiev Ukraine manufacturer PC090 ratio 2.45 pre-stage gearbox transmission reduction gear unit With high quality best price & service

Producer & distributor of roller & wire rope end chains. Sorts of chains incorporate alloy, substantial tensile transport, higher take a look at & proof coil chains. Applications contain log chains, cargo lashings, pipe line handA worm equipment system is made up of a worm and worm wheel. The worm resembles a screw, which fulfills with a worm wheel, as revealed in the photograph. When rotational electricity is utilized to the worm, it rotates against the wheel and transfers energy to the worm wheel. The method is created so that the worm can simply flip the gear, but the equipment are not able to turn the worm. In some designs, the friction between the gear and worm holds the worm in spot. This attribute can be extremely helpful in some programs.ing, tailgates, guard rails & switch chains. It has set up steady cooperation with numerous properly acknowledged universities and institutes in china these kinds of as, Zhejiang College, Jilin College, Technological committee of countrywide chain generate standard, Institute of national chain generate, Zhejiang software engineering substance institute, Huhan material safety institute and it cooperated to identified China 1st Car chain institute with Nationwide chain drive institute.

Overview

Quick Specifics

- Applicable Industries:

-

precision machinery

- Gearing Arrangement:

-

Helical

- Output Torque:

-

*

- Input Speed:

-

≤1500 rpm

- Output Speed:

-

*

- Spot of Origin:Zhejiang, China

- Brand name Name:

-

OEM

- Item title:

-

helical gearbox reduction

- Ingress Defense:

-

IP65

- Ratio:

-

2.forty five

- Shade:

-

grey /blue

- Heat remedy:

-

surface area hardening

- Housing Material:

-

aluminum alloy

Supply Ability

- Source Capacity:

- 200000 Piece/Parts for each Month

Packaging & Shipping

- Port

- Ningbo/Shanghai/ China Port

-

Lead Time

: -

Amount(Sets) one – one thousand >1000 Est. Time(days) 30 To be negotiated

On the web Customization

Ever-electrical power Team Co., Ltd. is Professional IN Generating ALL Sorts OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Gear Velocity REDUCERS, PARALLEL SHAFT HELICAL Gear REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Equipment REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Auto GEARBOXES, PTO Push SHAFTS, Particular REDUCER & Related Equipment Components AND OTHER Related Items, SPROCKETS, HYDRAULIC Program, VACCUM PUMPS, FLUID COUPLING, Equipment RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Equipment PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Reduced BACKLASH WORM REDUCERS AND SO ON. Moreover, WE CAN Generate Tailored VARIATORS, GEARED MOTORS, Electric MOTORS AND OTHER HYDRAULIC Products According TO Clients DRAWINGS.

HangZhou Ever-PowerMechanical & Electrical Co., Ltd. is a specialist maker ofgearbox and motors.The factory covers an spot of 20,000 square meters, the building region of thirty,000 square meters, the overall number of workers is far more than two hundred .We have handed theISO9001:2015global top quality management system common certification,CCCnationwide obligatory solution certificate andCEcertificate . We have developed sophisticated management software such asERPto hold speed with international standard.In buy to serve customers better the business actively cooperates with schools and universities to build new merchandise and boost present items .

|

Q1. Are you investing company or maker? A. We are maker Found in Taizhou Town of East China. Q2. How is promise of the high quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled examine and document materials and semi-finished spare elements. And – one hundred% inspect concluded spare areas just before put in storage. – 100% inspect just before assembly. – 100% examine before packaging. Q3. What information shall we give just before putting a purchase get? We can provide specialized assistance and the drawing according to your necessity if you make contact with with me. This autumn. What industries are your gearboxes being employed? Our gearboxes are extensively used in the places of textile, foodstuff processing, bever”EPG” manufacturer rotocultivator ploughshares in T.S. whole strains developed in our manufacturing facility have been tested and appraised by the Ministry of Agriculture and have The lemon tube is ideal for transmissible electricity of 16-35HP, it is the chosen option for substantial speeds and low torque transmission. The two-lobe lemon tube grants lower vibrations up to 2600 rpm with lengths not exceeding 800mm. AC collection with 6-lobe tubes (star)attained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China. age, chemical industry,escalator,automatic storage gear, metallurgy, tabacco, environmental protection, logistics and and many others. Q5. Do you have guarantee services? Indeed, the gearbox is free of charge guarantee inside 1 a long time following shipping. |

||||||

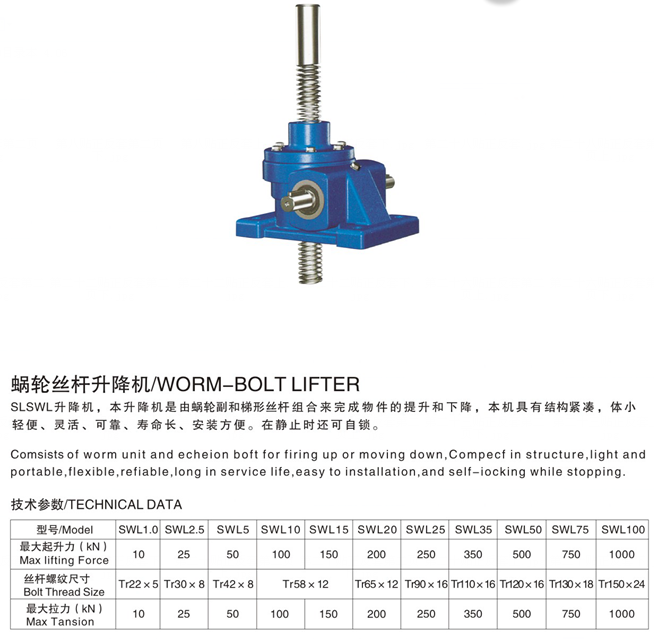

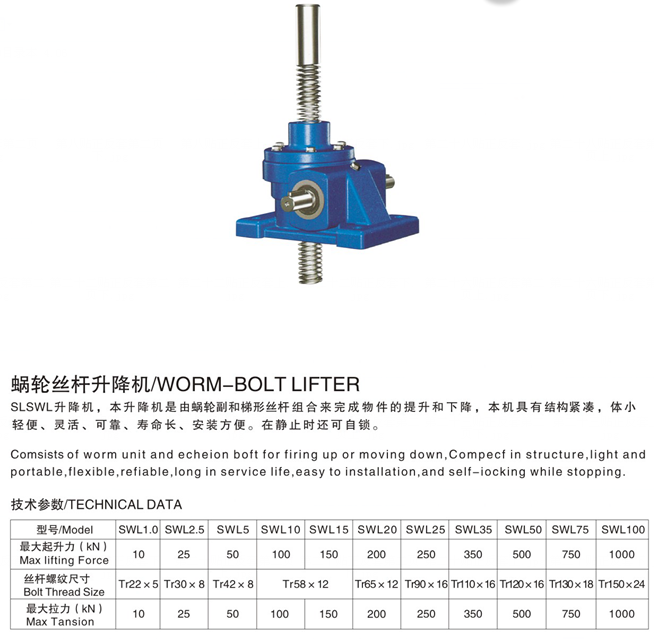

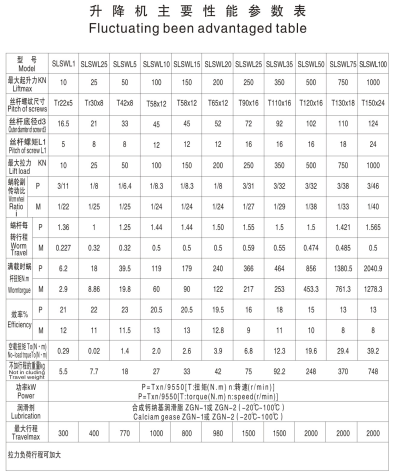

Best China manufacturer & factory SWL in Aurangabad India worm lifter gear screw jack power transmission hoist gearbox tricycle speed transmission gearbox small differential gear box With high quality best price

we have obtained the trust of buyers worldwide. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Output Torque:

-

9550

- Input Speed:

-

9550

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Certification:

-

ISO9001-2008

- Lifting Capacity:

-

request

- Lifting Height(mm):

-

customized

- Overall Width(mm):

-

As request

- Gear material:

-

Low carbon high alloy steel

- Heat treatment:

-

Carburising, quenching, gear grinding

- Diameter & Length of Screw:

-

Maintenance This kind of gear reducer is provided with a permanent lubrication, so it does not need any kind of maintenance.

Designed as request

- Bearing:

-

U&C

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Standard exporting package

- Port

- Ningbo Port, Shanghai Port

Online Customization

Product Description

SWL worm gear screw jack lifter has the features of compacted structure, light and portable, flexible, reliable, long service life, easy to installation, and self-locking while stop.

Certifications

Trade Shows

Packaging & Shipping

Packing Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Related Products

Contact

AT series with tri-lobe tube (triangular) The triangular tube shape is the most used, from lightweight to fairly heavy applications. In the case of applications with high sliding, the R version with Rilsan coating is also available. AL series with two-lobe tubes (lemon).

RC China series helicopter agricultural machine small helical gearbox range reduction gearbox speed reducer drive transmission – Supplier Manufacturer wholesaler Factory

For a lot more info.: Cell/Whatpp: +8613083988828

Great interest has been paid on environmental protection and strength saving. Our merchandise are selling effectively in Chinese marketplaces and some items offered in intercontinental markets are properly gained by Chinese and overseas customers at property and overseas.

Overview

Fast Details

- Relevant Industries:

-

Lodges, Garment Shops, Creating Material Outlets, Producing Plant, Machinery Mend Shops, Foods & Beverage Factory, Farms, Development works

- Spot of Origin:Zhejiang, China

- Model Name:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

three.five~500N.m

- Enter Pace:

-

1450/960rpm

- Output Velocity:

-

fourteen-280rpm

- Ratio:

-

three.77~50.four

- Certification:

-

ISO9001-2008

- Mount Placement:

-

Foot Mounted

- Bearing:

-

C&U,LYC, HRB,ZWZ,SKF,NSK

Supply Ability

- Source Capacity:

- 500 Unit/Models per Thirty day period

Packaging & Shipping

- Packaging Specifics

- Wood containers , Cantons packed in one pallet

- Port

- Ningbo Port, Shanghai Port

On-line Customization

RC series helicopter agricultural device little helical gearbox variety reduction gearbox speed gearbox generate transmission

Item Description

The highly modular is a style functions of SRC helical gearboxes assortment. It can be linked respectively with motors such as typical motor,brake motor,explosion-proof motor,frequency conversion motor,servo motor,IEC motor and so on. This type of solution is widely utilized in push fields this sort of as textile,foodstuff,ceramics packing,logistics,plastics and so on. It is possible to set up the edition necessary employing flanges or ft.

Merchandise attributes:

SLRC collection helical gear models has more than four varieties,electricity .12kw-4kw,ratio3.66-54max torque120-500NM,It can be linked(foot or flange)discretionary and use multi-mounting positions according customers’ demands

1 Floor-hardened helical gears

2. Modularity, can be merged in a lot of varieties

3. Aluminum casing, light weight

four. Gears in carbonize tough,resilient

five. Universal mounting

6. Refined layout, compact in composition and minimal sounds

| Certification | ISO9001-2008 |

| Bearing | C&U |

| Shade | Blue/black |

| Ratio | three.seventy seven~fifty.four |

| Mount Situation | Foot Mounted |

| Bearing | LYC, HRB,ZWZ,SKF,NSK |

Company Information

Packaging & Delivery

Our Providers

Certifications

Connected Products

Speak to us

FAQ

: Are you investing business or manufacturer ?

A: We are factory.

Q: How long is your shipping time?

A: Typically it is 5-ten times if the merchandise are in stock. or it is 15-20 times if the goods are not in stock, it is according to quantity.

Q: Do you offer samples ? is it free of charge or added ?

A: Of course, we could offer the sample for free cost but do not spend the cost of freight.

Q: What is your conditions of payment ?

A: Payment=1000USD, thirty% T/T in advance ,stability ahead of shippment.

If you have yet another query, pls truly feel totally free to make contact with us as under:

EPG – one of the greatest transmission factory in China, principal goods: worm geared motors, agricultrual gearbox, planetary equipment drive, helical,screw, beve gears and spare areas and agricultural components manunfacuter in ChinaFor far more information.: Cell/Whatpp: +8613083988828

R Custom Solutions Available series industry transmission helical speed gearbox worm geard motor 7.5kw speed reducer

In 2008, it was awarded with “Nationwide Export Commodity Inspection-cost-free Enterprise”.

Overview

Quick Specifics

- Applicable Industries:

-

Lodges, Garment Retailers, Developing Material Shops, Producing Plant, Equipment Repair Outlets, Meals & Beverage Manufacturing unit, Farms, Energy & Mining, Development performs

- Location of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Input Speed:

-

1400rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

seven.5~one hundred

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

LYC

Supply Capacity

- Provide Ability:

- 500 Device/Models for each Thirty day period

Packaging & Delivery

- Packaging Specifics

- Wooden bins , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

On the web Customization

R sequence sector transmission inline helical speed gearbox worm geard motor seven.5kw velocity reducer

Product Description

SLR helical reducer has the functions of high flexibility,very good mixture and large loading functionality, together with other deserves this sort of as effortless to attain different transmission ratios, large performance, reduced vibrationand large permissible axis radial load. This series can not only be blended with various kinds of reducers and variators and satisfy the needs, but also beadvantage of localization of connected transmission tools.

Specs:

1) Output speed: .six~one,028r/min

two) Output torque: up to eighteen,000N.m

three) Motor electricity: .eighteen~160kW

four) Mounted sort: foot-mounted and flange-mounted mounting

|

Merchandise Title |

SLR Collection Rigid Tooth helical reducer |

|

Equipment Material |

20CrMnTi |

|

Scenario Materials |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding complete by HOFLER Grinding Equipment |

|

Color |

Custom-made |

|

Sound Take a look at |

Bellow 65dB |

Firm Information

Certifications

Our Companies

Packaging & Delivery

Related Merchandise

FAQ

: Are you buying and selling firm or maker ?

A: We are manufacturing facility.

Q: How prolonged is your shipping time?

A: Normally it is five-10 days if the merchandise are in stock. or it is 15-twenty days if the products are not in stock, it is according to quantity.

Q: Do you give samples ? is it totally free or additional ?

A: Indeed, we could offer the sample for cost-free demand but do not pay out the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, thirty% T/T in advance ,equilibrium prior to shippment.

If you have one more concern, pls really feel totally free to speak to us as beneath:

Contact us