Product Description

Spline Round Key Way Pin Threaded CZPT Hollow Through Hole Flat D Shape Knurling Spur Helical Worm Transmission Drive Auto Parts Gear Pinion Gearbox Axis Shaft

Features

1. High precision gear shaft for smooth, quiet operation.

2. Flexible for custom-made requests.

3. Stable transmission, low impact, vibration, and noise.

4. Heavy Load capability, more compact, but less complex.

Product Description

| Products | Spur Gear, Helical Gear, Herringbone Gear, Spiral Bevel Gear, Straight Bevel Gear, Worm Gear, Shaft, Pinion |

| Module | M0.3-M10 |

| Precision grade | DIN6, DIN7, DIN8, DIN10 |

| Pressure angle | 14.5 degree, 15 degree, 20 degree |

| Material | Medium Carbon Steel: 35#, 45# Carburizing Steel: 20CrMnTi, 20CrMnMo, 20CrMo Alloy Steel: 40Cr, 35CrMo, 42CrMo, 40CrNiMo Cast Iron: HT250, QT400 Copper, Stainless Steel, Brass, Nylon, POM, and so on |

| Heat treatment | Hardening & Tempering, Surface Quenching, Integral Quenching, Carburizing Quenching, Tempering, Normalizing, Nitriding |

| Surface treatment | Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

| Application | Gearbox and reducer; Precision cutting machines, Lathes machines; Milling machines; Grinder machine; Automated mechanical systems; Automated warehousing systems. Gear hobbing machines, gear shapers, gear shaving machines, gear milling, gear grinding machines and many kinds of gear-related machines. |

| Machining process | Forging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment… |

Detailed Photos

Our Advantages

Related Product

Company Profile

FAQ

Q: How to ship the worm gear to us?

A: It is available by air, sea, or train.

Q: How to pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Gearbox |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample Worm gear with shaft

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

How do drive shafts handle variations in load and vibration during operation?

Drive shafts are designed to handle variations in load and vibration during operation by employing various mechanisms and features. These mechanisms help ensure smooth power transmission, minimize vibrations, and maintain the structural integrity of the drive shaft. Here’s a detailed explanation of how drive shafts handle load and vibration variations:

1. Material Selection and Design:

Drive shafts are typically made from materials with high strength and stiffness, such as steel alloys or composite materials. The material selection and design take into account the anticipated loads and operating conditions of the application. By using appropriate materials and optimizing the design, drive shafts can withstand the expected variations in load without experiencing excessive deflection or deformation.

2. Torque Capacity:

Drive shafts are designed with a specific torque capacity that corresponds to the expected loads. The torque capacity takes into account factors such as the power output of the driving source and the torque requirements of the driven components. By selecting a drive shaft with sufficient torque capacity, variations in load can be accommodated without exceeding the drive shaft’s limits and risking failure or damage.

3. Dynamic Balancing:

During the manufacturing process, drive shafts can undergo dynamic balancing. Imbalances in the drive shaft can result in vibrations during operation. Through the balancing process, weights are strategically added or removed to ensure that the drive shaft spins evenly and minimizes vibrations. Dynamic balancing helps to mitigate the effects of load variations and reduces the potential for excessive vibrations in the drive shaft.

4. Dampers and Vibration Control:

Drive shafts can incorporate dampers or vibration control mechanisms to further minimize vibrations. These devices are typically designed to absorb or dissipate vibrations that may arise from load variations or other factors. Dampers can be in the form of torsional dampers, rubber isolators, or other vibration-absorbing elements strategically placed along the drive shaft. By managing and attenuating vibrations, drive shafts ensure smooth operation and enhance overall system performance.

5. CV Joints:

Constant Velocity (CV) joints are often used in drive shafts to accommodate variations in operating angles and to maintain a constant speed. CV joints allow the drive shaft to transmit power even when the driving and driven components are at different angles. By accommodating variations in operating angles, CV joints help minimize the impact of load variations and reduce potential vibrations that may arise from changes in the driveline geometry.

6. Lubrication and Maintenance:

Proper lubrication and regular maintenance are essential for drive shafts to handle load and vibration variations effectively. Lubrication helps reduce friction between moving parts, minimizing wear and heat generation. Regular maintenance, including inspection and lubrication of joints, ensures that the drive shaft remains in optimal condition, reducing the risk of failure or performance degradation due to load variations.

7. Structural Rigidity:

Drive shafts are designed to have sufficient structural rigidity to resist bending and torsional forces. This rigidity helps maintain the integrity of the drive shaft when subjected to load variations. By minimizing deflection and maintaining structural integrity, the drive shaft can effectively transmit power and handle variations in load without compromising performance or introducing excessive vibrations.

8. Control Systems and Feedback:

In some applications, drive shafts may be equipped with control systems that actively monitor and adjust parameters such as torque, speed, and vibration. These control systems use sensors and feedback mechanisms to detect variations in load or vibrations and make real-time adjustments to optimize performance. By actively managing load variations and vibrations, drive shafts can adapt to changing operating conditions and maintain smooth operation.

In summary, drive shafts handle variations in load and vibration during operation through careful material selection and design, torque capacity considerations, dynamic balancing, integration of dampers and vibration control mechanisms, utilization of CV joints, proper lubrication and maintenance, structural rigidity, and, in some cases, control systems and feedback mechanisms. By incorporating these features and mechanisms, drive shafts ensure reliable and efficient power transmission while minimizing the impact of load variations and vibrations on overall system performance.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2023-12-13

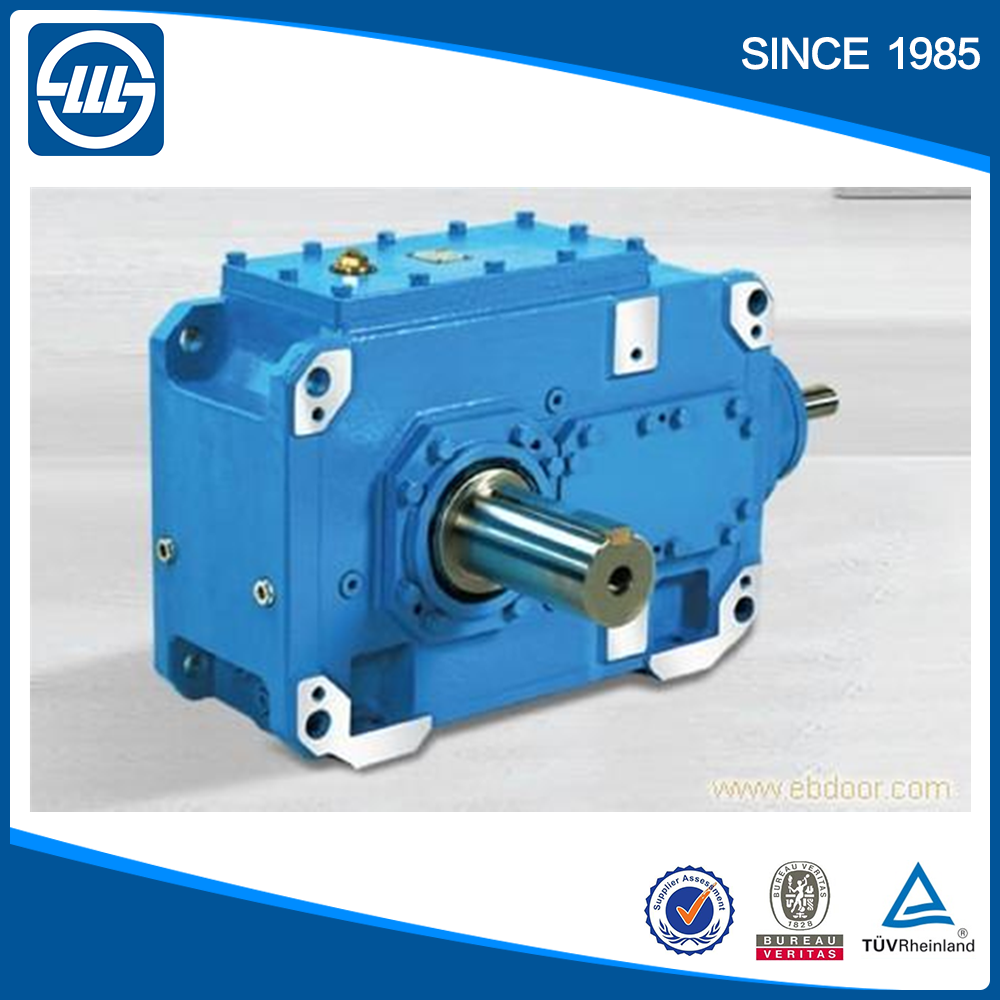

China Best Sales Kaf107 Helical Bevel Transmission Gearbox Right Angle Shaft with 7.5kw Motor for Tower Cranes with Hot selling

Merchandise Description

SC Transmission helical-bevel geared motor KAF107

helical-bevel geared motor KAF sequence

product:KAF37,KAF47,KAF57,KAF67…..KAF157

one:KAF B5 flange mounted with hollow shaft

two:KVF B5 flange mounted with splined hollow shaft

three:KHF B5 flange mounted with foot mounted and hollow shaft and shrink disk

Features:

- Higher effectiveness: 92%-93%

- Vertical output, compact composition, difficult tooth surface , big output torque, low noise and long service life.

- Higher precision: the equipment is created of substantial-quality alloy metal forging, carbonitriding and hardening treatment, grinding approach to guarantee higher precision and steady operating.

- Large interchangeability: highly modular, serial style, robust flexibility and interchangeability.

cyc lo equipment box box

| Ratio | 5.36-197.37 |

| Input power | 0.12-200KW |

| Output torque | 10–62800N.m |

| Output speed | 7-415rpm |

| Mounting type | Foot mounted, foot mounted with solid shaft, output flange mounted, hollow shaft mounted, B5 flange mounted with hollow shaft, foot mounted with hollow shaft, B14 flange mounted with hollow shaft, foot mounted with splined hole, foot mounted with shrink disk, hollow shaft mounted with anti-torque arm. |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

| Brake Release | HF-manual release(lock in the brake release position), HR-manual release(autom-atic braking position) |

| Thermistor | TF(Thermistor protection PTC thermisto) TH(Thermistor protection Bimetal swotch) |

| Mounting Position | M1, M2, M3, M4, M5, M6 |

| Type | K37-K157 |

| Output shaft dis. | 25mm, 30mm, 35mm, 40mm, 50mm, 60mm, 70mm, 90mm, 110mm, 120mm |

| Housing material | HT200 high-strength cast iron from R37,47,57,67,77,87 |

| Housing material | HT250 High strength cast iron from R97 107,137,147, 157,167,187 |

| Heat treatment technology | carbonitriding and hardening treatment |

| Single Stage Efficiency | up to 96% |

| Lubricant | VG220 |

| Protection Class | IP55, F class |

| Ratio | 5.36-197.37 |

| Input power | 0.12-200KW |

| Output torque | 10–62800N.m |

| Output speed | 7-415rpm |

| Mounting type | Foot mounted, foot mounted with solid shaft, output flange mounted, hollow shaft mounted, B5 flange mounted with hollow shaft, foot mounted with hollow shaft, B14 flange mounted with hollow shaft, foot mounted with splined hole, foot mounted with shrink disk, hollow shaft mounted with anti-torque arm. |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

| Brake Release | HF-manual release(lock in the brake release position), HR-manual release(autom-atic braking position) |

| Thermistor | TF(Thermistor protection PTC thermisto) TH(Thermistor protection Bimetal swotch) |

| Mounting Position | M1, M2, M3, M4, M5, M6 |

| Type | K37-K157 |

| Output shaft dis. | 25mm, 30mm, 35mm, 40mm, 50mm, 60mm, 70mm, 90mm, 110mm, 120mm |

| Housing material | HT200 high-strength cast iron from R37,47,57,67,77,87 |

| Housing material | HT250 High strength cast iron from R97 107,137,147, 157,167,187 |

| Heat treatment technology | carbonitriding and hardening treatment |

| Single Stage Efficiency | up to 96% |

| Lubricant | VG220 |

| Protection Class | IP55, F class |

Drive shaft type

The driveshaft transfers torque from the engine to the wheels and is responsible for the smooth running of the vehicle. Its design had to compensate for differences in length and angle. It must also ensure perfect synchronization between its joints. The drive shaft should be made of high-grade materials to achieve the best balance of stiffness and elasticity. There are three main types of drive shafts. These include: end yokes, tube yokes and tapered shafts.

tube yoke

Tube yokes are shaft assemblies that use metallic materials as the main structural component. The yoke includes a uniform, substantially uniform wall thickness, a first end and an axially extending second end. The first diameter of the drive shaft is greater than the second diameter, and the yoke further includes a pair of opposing lugs extending from the second end. These lugs have holes at the ends for attaching the axle to the vehicle.

By retrofitting the driveshaft tube end into a tube fork with seat. This valve seat transmits torque to the driveshaft tube. The fillet weld 28 enhances the torque transfer capability of the tube yoke. The yoke is usually made of aluminum alloy or metal material. It is also used to connect the drive shaft to the yoke. Various designs are possible.

The QU40866 tube yoke is used with an external snap ring type universal joint. It has a cup diameter of 1-3/16″ and an overall width of 4½”. U-bolt kits are another option. It has threaded legs and locks to help secure the yoke to the drive shaft. Some performance cars and off-road vehicles use U-bolts. Yokes must be machined to accept U-bolts, and U-bolt kits are often the preferred accessory.

The end yoke is the mechanical part that connects the drive shaft to the stub shaft. These yokes are usually designed for specific drivetrain components and can be customized to your needs. Pat’s drivetrain offers OEM replacement and custom flanged yokes.

If your tractor uses PTO components, the cross and bearing kit is the perfect tool to make the connection. Additionally, cross and bearing kits help you match the correct yoke to the shaft. When choosing a yoke, be sure to measure the outside diameter of the U-joint cap and the inside diameter of the yoke ears. After taking the measurements, consult the cross and bearing identification drawings to make sure they match.

While tube yokes are usually easy to replace, the best results come from a qualified machine shop. Dedicated driveshaft specialists can assemble and balance finished driveshafts. If you are unsure of a particular aspect, please refer to the TM3000 Driveshaft and Cardan Joint Service Manual for more information. You can also consult an excerpt from the TSB3510 manual for information on angle, vibration and runout.

The sliding fork is another important part of the drive shaft. It can bend over rough terrain, allowing the U-joint to keep spinning in tougher conditions. If the slip yoke fails, you will not be able to drive and will clang. You need to replace it as soon as possible to avoid any dangerous driving conditions. So if you notice any dings, be sure to check the yoke.

If you detect any vibrations, the drivetrain may need adjustment. It’s a simple process. First, rotate the driveshaft until you find the correct alignment between the tube yoke and the sliding yoke of the rear differential. If there is no noticeable vibration, you can wait for a while to resolve the problem. Keep in mind that it may be convenient to postpone repairs temporarily, but it may cause bigger problems later.

end yoke

If your driveshaft requires a new end yoke, CZPT has several drivetrain options. Our automotive end yoke inventory includes keyed and non-keyed options. If you need tapered or straight holes, we can also make them for you.

A U-bolt is an industrial fastener that has U-shaped threads on its legs. They are often used to join two heads back to back. These are convenient options to help keep drivetrain components in place when driving over rough terrain, and are generally compatible with a variety of models. U-bolts require a specially machined yoke to accept them, so be sure to order the correct size.

The sliding fork helps transfer power from the transfer case to the driveshaft. They slide in and out of the transfer case, allowing the u-joint to rotate. Sliding yokes or “slips” can be purchased separately. Whether you need a new one or just a few components to upgrade your driveshaft, 4 CZPT Parts will have the parts you need to repair your vehicle.

The end yoke is a necessary part of the drive shaft. It connects the drive train and the mating flange. They are also used in auxiliary power equipment. CZPT’s drivetrains are stocked with a variety of flanged yokes for OEM applications and custom builds. You can also find flanged yokes for constant velocity joints in our extensive inventory. If you don’t want to modify your existing drivetrain, we can even make a custom yoke for you.

in Douala Cameroon sales price shop near me near me shop factory supplier Output Shaft with Helical Gear Motor Gearbox Ncjt02 Series manufacturer best Cost Custom Cheap wholesaler

Thanks to our vast product variety and abundant experiences in this industry, our merchandise are selling properly in the American, European, South American and Asian markets. we are self-assured to supply our customers adaptable and diversified companies. Output Shaft with EPTcal EPT EPT EPTT NCJT02 Series

one.Item features

one.one. NCJ Series EPTcal EPTmotor

one.two. EPT Efficienty:up to ninety two%-96%

one.three. EPT wide voltage motor,functioning typically unEPTTfull-load: twenty-60Hz

1.4. EPT pair processed by carburizing and quenching warmth therapy:fifty eight-62EPTC

one.five. EPT EPT grease:6105GT,2000 opearting hrs,maintenance totally free

one.6. Reduced temperature increase:35 degC-42 degC(full load)

1.7. Iron Solid:EPTT200

one.eight. Low vitality consumpition,minimal sounds,modest vabration and larget torque

two. EPTnical parameters

| Variety | EPTcal EPTed motor |

| Design | NCJ02-NCJ05 |

| Ratio | eight-a hundred and forty |

| EPTT | blue or OEM colors |

| EPT | EPTT200 Iron solid |

| EPTT | C ampU |

| Seal | SKF,NAK |

| Input EPTT | .12-4KW |

| Usages | this kind of as EPTT,Iron and metal,chemical,oil,EPTTarge,food,electronics,leather-based,pharm-aceutical, textile EPTT and so on |

| Mounting type | Foot mounted,flange mounted |

| Lubricant | 6105GT EPTT EPT grease |

| Reduced temperature rise | 35 degC-forty two degC(complete load) |

| Hardness | 58-62EPTC |

| Broad voltage | 20-60Hz |

| EPT efficiency | 92%- 96% |

| EPT Pair | Processed by carburizing and quenching warmth therapy |

3.Purposes

HangEPT XG EPTT EPTT EPTT are extensively used in :

Ceramic Industry

Glass Business

Foodstuff Market

EPTlurgy Sector

Beer amp Consume Market

EPT and dyeing Business

EPT Industry

Warehouse Logoistics Market

EPT doing work EPTTry

environmental protection equipment Industry

Leather-based Market

Pharmacy Market

four.Our Services

four.one.We provide twelve months Warranty.

four.two. We have hundreds of EPTT EPTTs. From Input EPTT .06KW to 200KW, Ratio one.3-289.seventy four, Output velocity -1095rpm and Output torque one.4-62800Nm…They can meet up with your all different specifications for distinct EPTT.

four.three. We supply E-catalog or Paper catalog,so you can choose the product very easily according to your specifications

4.4.You are welcome to visit our factory to check our merchandise,we can support you to guide the hotel or ticket

5.EPTT Info

five.1.Our EPTT:

The Predecessor for ZheJiang EPT EPTT,Ltd (originally called HangEPT XiHu (West EPT) Dis.ngguang EPTT EPTTry EPTT,Ltd) Point out-owned army mould EPTTrpriese which estabEPTTd in 1965.

EPT is found in HangEPT,EPTT and the factory handles an area of about 25000 sq. meters.

Creation Ability:a lot more than fifty percent a million sets of speed EPTT for every 12 months.

5.two.Our People:

The business has a robust complex drive. It has far more than four hundred staff at existing, incXiHu (West EPT) Dis.Hu (West EPT) Dis. a lot more than 40 engineering experts and ten professionals and senior engineers enEPTTing EPTT allowances of the State Council.

5.3. Our Certificates:

Handed quot ISO 9001 Worldwide EPTT Method Certification quot, quotInternational EPTT Credit AAA Ceritifacte quot , quot Swiss SGS Certification quot, Legendary Model in EPTT EPTT Sector quot, quotFamous Manufacturer of ZheJiang Province quot, quotNon-general public Scientific and EPTnological EPTTrprise in ZheJiang Province quot, quotNational EPT and EPTT-tech EPTTrprise quot, quotTOP 50 in EPTT EPT Industry quot quot2011 HangEPT EPT and EPTnological R ampD CEPTTr quot and so on.

6. FAQ

Q:Are you a buying and selling company or manufacturer?

A: The predecessor of HangEPT XG-EPTT EPTTry EPTT, Ltd is Condition-owned XiHu (West EPT) Dis.ngguanggong Mildew Manufacturing facility, a point out-owned armed forces EPTT EPTTrprise estabEPTTd in 1965. It accomplished reform in 2002. Because reform, EPT has deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ed speedily. It took the lead in passing ISO9001 International EPTT Program Certificate and Worldwide EPTT Credit rating AAA Certification in 2004, and Swiss SGS Certification in 2009. It has gained this sort of titles as quotIconic Brand name in EPTT EPTT Sector quot, quotFamous Model of ZheJiang Province quot, quotNon-public Scientific and EPTnological EPTTrprise in ZheJiang Province quot, quotNational EPT and EPTT-tech EPTTrprise quot, and quotTope fifty in EPTT EPT Market quot successively

Q:The place do you foundation?

A: We are in HangEPT,ZheJiang ,EPTT. We have two factories,EPTT manufacturing facility is in XiHu (West EPT) Dis.hu (West EPT) Dis. district,HangEPT,EPTT and the previous one particular is in CHangEPT District,HangEPT,EPTT.

Q:What sorts of EPTT can you generate for us?

A:Principal goods of our company: JWB-X sequence mechanical constantly variable EPTT, RV series worm EPT EPTT, B/JXJ cycloidal pin EPT velocity EPTT, NCJ sequence EPT EPTT, and R, S, K, and F collection helical-tooth EPTT, far more than one hundred versions and thousands of specifications.

Q:What are the application of the EPTT?

A:EPT are widely utilized in ceramic, EPT, food, metallurgy, beer amp consume, printing and dyeing, textile, petrochemical engineering, warehouse EPT, wood-functioning EPTT, environmental protection gear, printing and EPTT, pharmacy, and leather-based. EPT are offered in some international locations and areas, such as Europe, The united states, and SouthEPT Asia, and it possesses dozens of distributors and right after-sale provider brokers.

Q:What is the substance you use?

A: EPTT scenario ( For the RV collection worm EPTT,product RV030-one zero five)

Solid iron(For the RV series worm EPTT, design RV110-150, For the NCJ /F/R/S/K series helical EPT EPTT)

in Gorakhpur India sales price shop near me near me shop factory supplier K Series Inline Motor Helical Bevel Gear Reducer Gearbox with Flange manufacturer best Cost Custom Cheap wholesaler

PersonnelOur product sales persons are nicely qualified to accommodate your requests and converse English for your comfort. The team is focused on producing all range of standard roller chains and sprockets, gears & gearboxes, such as conveyor chain & sprockets , stainless steel chain, agricultural chain and has not just offered its merchandise all in excess of china, but also offered a lot more than 65% merchandise to oversees, which includes Europe, The us, South-east Asia, and it also has set up storage logistics in areas like Europe. In 2008, it was awarded with “Countrywide Export Commodity Inspection-free of charge Business”.

K (as SEW) Collection Large Effectiveness Gear Velocity EPT with EPT or without EPT

one.Our Solutions 1.1.We provide twelve months Warranty. 2.Organization Info two.one.Our Organization: EPT is found in HangEPT,EPT and the manufacturing unit covers an area of about 25000 sq. meters. Manufacturing Ability:more than half a million sets of velocity EPT for every yr. two.two.Our People: 2.3. Our Certificates: three. FAQ Q:Are you a buying and selling business or manufacturer? Q:Exactly where do you base? Q:What types of EPT can you produce for us? Q:What are the software of the EPT? Q:What is the materials you use? A1: EPT EPT human body ( For the RV sequence worm EPT Dimension thirty~ninety) A2: Cast iron(For the RV series worm EPT, Dimension a hundred and ten-150, For the NCJ amp F/R/S/K series helical EPT EPT) Our manufacturing facility (ZheJiang EPT Travel Co., Ltd.) is a massive and renowned 6S stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT factory with about 380 employees since 1965 . We export to South Asia, SouthEPT Asia, Africa, Center EPT, South The us, North The us, Europe…and so forth. We provide EPT to SIEMENS,ABB,SACMI,BUHLER,MODENA,EPT…etc. Sincerely hope to set up a earn-get enterprise partnership with you. Expecting to chat about more details with you ! Best Wishes Jacky |

China manufacturer & factory supplier for Swl in Kakinada India worm bolt lifter jack screw adjuster speed variator parallel shaft helical gearbox swl bevel gear screw jack worm gear With high quality best price & service

ISO 9001:2015 accredited producer and distributor of roller chains. Sorts of roller chains consist of ASME/ANSI regular chains, attachment chains, corrosion resistant chains, lube-free chains, plastic chains, free of charge-circulation chains, specialty chains and British normal chains. ASME/ANSI normal chains are offered in huge and small pitch, double pitch and leaf designs. Roller chains are utilized in food packaging, forklift vehicles, oilfield drilling, motorcycles, conveyors and power transfer purposes.Getting accrued treasured encounter in cooperating with foreign customers, a specialised supplier of a complete assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Constructing Content Outlets

- Output Torque:

-

Shut up of two yokes with the common joint. Note the slight oozing of grease from the UJ seal finishes, the clump of grease is from inside of the yoke splined shaft location –Travel (outer) yoke has a female (usual spline) hole and “Y” shape finish that is the common joint (UJ) mount. –UJ is a cross shaped casting having roller bearings enclosed with caps at all four factors and is held into the yoke with 4 “C” clips –Internal yoke and generate shaft is yet another yoke welded to the generate end, of the drive shaft. –Pushed shaft and interior yoke is the pushed shaft that rides inside of of the travel shaft and has a yoke welded at the pushed end –UJ another UJ as earlier mentioned

1.8-2430N.M

- Enter Velocity:

-

Principal goods incorporate: manure spreading truck, potato planting/harvesting equipment, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, mix rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its equipment: Plow disc blades, harrowing movie, plough tip and share, cultivator tine, casting elements etc.

750-1500rpm

- Output Pace:

-

.sixty four-350rmp

Structural functions The worm equipment consists of three essential parts : housing, worm and wheel.

- Spot of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Certification:

-

ISO9001-2008

- Equipment material:

-

Low carbon high alloy metal

- Heat treatment method:

-

Carburising, quenching, gear grinding

- Diameter & Length and Lifting Top:

-

Made as request

- Bearing:

-

C&U

- gear precision quality:

-

din 4

Offer Potential

- Offer Potential:

- five hundred Unit/Models for each Thirty day period

Packaging & Supply

- Packaging Information

- Regular exporting package

- Port

- Ningbo Port, Shanghai Port

-

Guide Time

: -

Quantity(Boxes) one – one >1 Est. Time(times) twenty To be negotiated

Online Customization

Swl worm bolt lifter jack screw adjuster pace variator parallel shaft helical gearbox swl bevel gear screw jack worm equipment

Benefit:

SWL Worm-bolt lifter has the attributes of compacted composition, gentle and moveable, versatile, trustworthy, extended service existence, easy to set up, and self-locking even though cease.

Software Industries:

SWL series screw jacks are widely utilized in industries this sort of as metallurgy,mining,hoisting and transportation, electrical power,strength resource, construction and constructing materials,light-weight sector and visitors industry

Packing Information : Standard carton/Pallet/Normal wood case

Shipping and delivery Specifics : 15-30 operating days upon payment

Q1: What details must I tell you to verify the product?

A: Model/Dimension, Transmission Ratio, Shaft instructions & Buy amount.

Q2: What can i do if I don’t know which a single I need?

A: Will not be concerned, Deliver as significantly information as you can, our team will support you discover the proper 1 you are hunting for.

Q3:What is your merchandise warrenty time period?

A:We offer you 1 calendar year warrenty because the vessel departure day remaining China.

If you have yet another question, pls really feel free of charge to get in touch with us.

R made in China – replacement parts – in Nurenberg Germany Series in Line Helical Geared Motor Speed Gearbox with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 diverse branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Merchandise Introduction:

In line helical geared motor is characterized by compact construction, light-weight excess weight, huge torque and excellent efficiency. Prompt shipping and delivery inside limited time.

It is made of rib-bolstered rigid circumstance and top quality alloy-steel gear which is hardened by carbon penetration and grinded exactly. Stable in working, lower noise, large in load, lower in usage, successful in transmission, minimal in temperature rise, and prolonged in services lifestyle.

The mounting variations are footing, flange, torque arm and so on. The output type are shaft, hollow shaft, the alpine and shrink disc are for choice.

Firm Profile

l The large EPT maker and exporter of worm gear reducers in Asia.

l Established in 1976, we remodeled from a county owned manufacturing facility to non-public one in 1996. HangZhou SINO-DEUTSCH Power TRANSMISSION Equipment CO.,L EPT is our new identify since 2001.

l We are the fir EPT manufacturer of reducers and gearboxes in China who was provided export license given that year 1993.

l “Fixedstar” manufacturer gearboxes and reducers are the fir EPT proprietor of CHINA Prime Brand and Mo EPT Well-known Trade Mark for reducers.

Fir EPT to achieve ISO9001 and CE Certificate among all manufacturers of gearboxes in China.

As a professional producer of worm gearbox and worm equipment reducers in China, we largely produce reduction gearbox,aluminum circumstance worm gearboxes,arc equipment cylindrical worm gearboxes, worm equipment reducers, in line helical gearboxes, and cyclo generate reducers, and so forth. These merchandise function rational structure, secure functionality, and reliable high quality, and so on. They are commonly employed in power, mining, metallurgy, constructing material, chemical, food, printing, ceramic, paper-producing, tobacco, and EPT industries.

We have 600 employees in our manufacturing facility, which addresses 70,000 square meters in HangZhou. We have been generating 2,500 units of reducers every day since 2012. We are proudly exporting 70% of our items to much more than 40 countries all in excess of the term. Our buyers occur from Italy, Germany, Usa, Canada, Spain, British isles, Mexico, Brazil, Argentina, Turkey, Singapore and EPT major industrial nations in the world. 30% of them are OEM created for direct companies of EPT items.

We warmly welcome clients from EPT areas of the world to check out us. Looking at is believing. We are really self-assured that after browsing our facility, you will have self-confidence on our items. We have the late EPT automated equipments and experienced personnel to make certain the secure good quality and huge output. We have the mo EPT sophisticated complex and engineering group to support mo EPT demanding requirement on common and OEM products.

Hunting ahead to conference you in HangZhou, China.

The use of authentic gear manufacturer’s (OEM) component numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the shown substitute components contained herein are not sponsored, authorized, or made by the OEM.

High qualtiy best price SMR Shaft Mounted helical speed reducer worm gearbox 40 bevel gear box shaft drive unit txt shaft mounted gear speed reducer supplier factory manufacturer & exporter in China

EPG was awarded with “famous product of Zhejiang Province” and “famous brand of Zhejiang Province”.

Overview

Quick Details

Applicable Industries: :

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, txt shaft mounted gear speed reducer

Gearing Arrangement: :

Helical

Output Torque: :

max 8000NM

Input Speed: :

1440

Output Speed: :

72, 110, 288

Place of Origin:Zhejiang, China Brand Name: :

OEM

Model Number: :

SMR

Rated Power: :

2.68~134.2

color of Shaft Mounted speed reducer: :

green blue gray

Supply Ability

Supply Ability: : 5000 Piece/Pieces per Month

Packaging & Delivery

Packaging Details: standard export packing and wood pallets packing Port: Shanghai or Ningbo Lead Time : :

| Quantity(Pieces) | 1 – 5000 | >5000 |

| Est. Time(days) | 30 | To be negotiated |

Online Customization

Product Description

Product Description

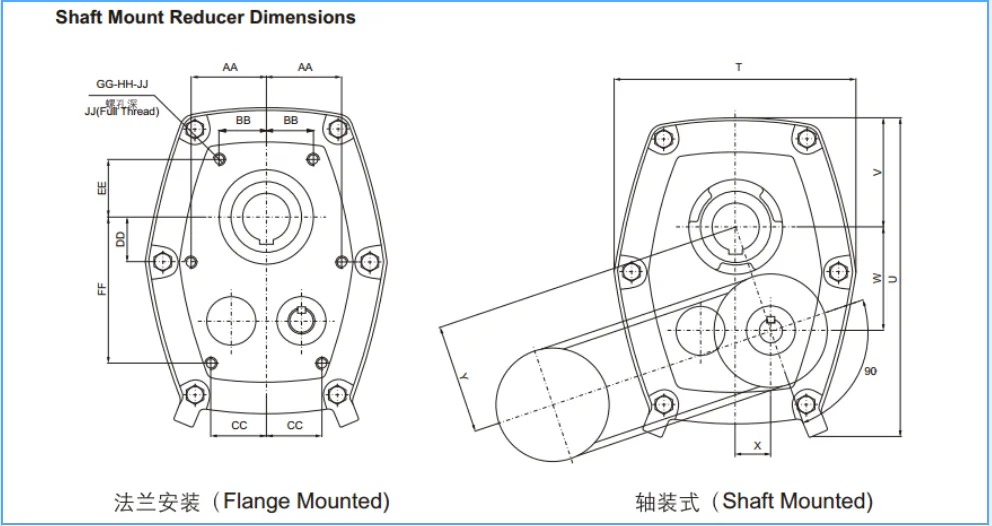

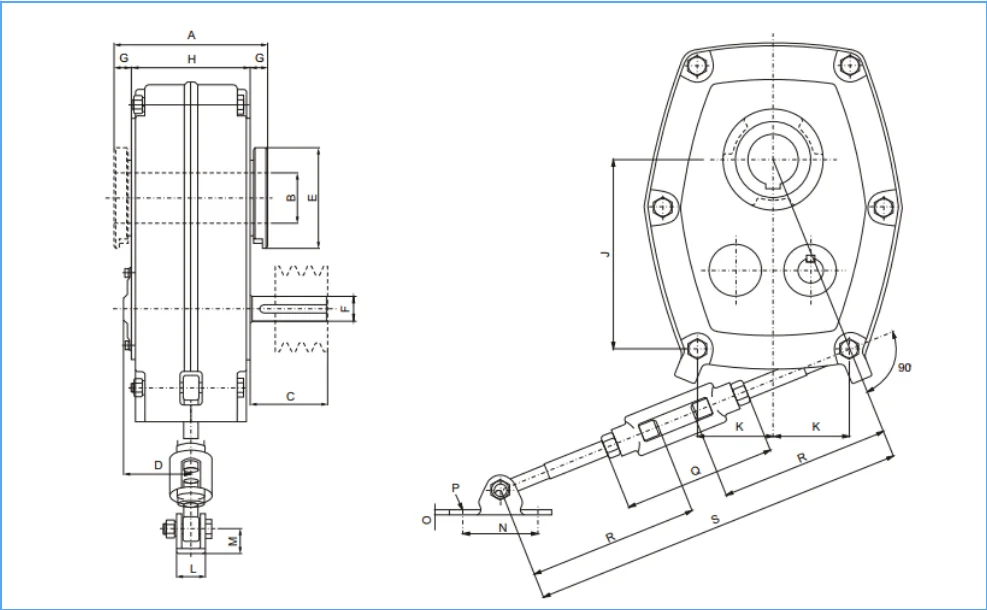

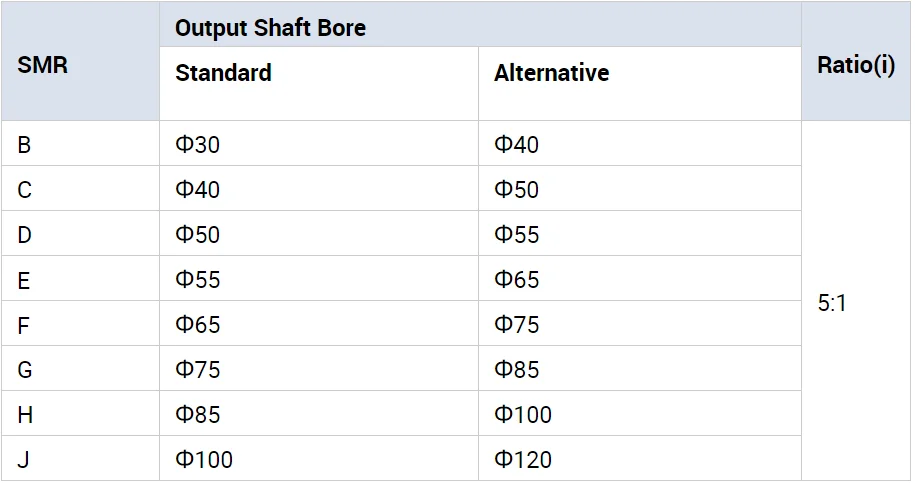

SMR Metric Series

Sizae: B-J

Ratio: 5:1, 13:1, 20:1

Maximum Output Torque: 8000 Nm

SMR Shafted mounted gear speed reducer:

1) Shafted mounted gear unit for conveyer systems

2) All gears are heat treated and fixed to achieve low noise and high output

3) Mounting dimensions are interchangeable with Fene

Product Paramenters

Product Paramenters

Related Products

RelaFURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS’ DRAWINGS.ted Products

Product packaging

Product pacOne aspect of our application consulting is that we have been collecting and combining the experience in chain and sprocket applications in various areas for decades. This is particularly interesting for us whenever customers approach us with some exceeding and challenging requirements.kaging

FAQ

FAQ

Q: Are you trading company or manufacturer ?

A: HZPT group consists in 3 factories and 2 abroad sales cooperations.we are making vacuum pumps,air compressors and gearboxes.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 30-45 days. The time may vary depending on the product and the level of customization. For standard products,

the payment is: 30% T/T in advance ,balance before shippment.,for customized products,50% downpayment is requested normally.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with detail size, material and further specifications;when you place orders,pleasure contact us in advance to communicate all details

Best China manufacturer & factory High quality B series heavy duty gearbox for extruder machine 90 Degree Parallel Shaft Reducer H B Series Helical Gearbox With high quality best price

There is a technical center of province level, EPG academician working station, experiment station for EPG post doctors, and national 863 program set up in EPG group. With these platforms and strong technical ability, the more than 400 technicians have developed all variety of special high precise and high strength products, conducted mold programs for key components in the car and national industry revitalizing program, resulting more than 5000 developed over, among which 33 items are autonomous patent technology with 4 patent approved .

Overview

Quick Details

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, restaurant, HOME USE, Retail, Food Shop, Printing Shops, Energy & Mining, Food & Beverage Shops, Advertising Company, Construction works

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Bevel / Miter

- Output Torque:

-

470000Nm

- Input Speed:

-

750-1500rpm

- Output Speed:

-

1.7~1200rpm

- Gear precision grade:

-

4

- Certification:

-

ISO9001-2008

- Mount Position:

-

horizontal/ vertical

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Standard wooden case

- Port

- Ningbo , Shanghai

-

Lead Time

: -

Quantity(Boxes) 1 – 1 >1 Est. Time(days) We warmly welcome the friends from all the world!

30 To be negotiated

Online Customization

Product Description

Product Description

High Quality 90 Degree Bevel Gear Reducer diesel engine with gear box Parallel Shaft Gear Reducer gearbox transmission

Advantage:

SLB series high power speed reducer has the features of high versatility,good combination and heavy loading capability, along with other merits such as easy to attain various transmission ratios, high efficiency, low vibration and high permissible axis radial load.

Specifications:

1) Output speed: 1.7~1200r/min

2) Output torque: up to 47,000N.m

3) Motor power: 2.52~5366kW

4) Mounted form: foot-mounted ,flange-mounted, axis mounted, shrink mounted

|

Product Name |

H/B series high power speed gear reducer industrial gearbox for concrete mixer |

|

Housing Material |

HT 250 Cast In close consultation with the customer, the design of special gearboxes and high-precision gearing components are individually customized to the technical and operational requirements. For special requirements such as HIGH SPEED, low noise or HIGH TORQUE, we develop optimal customer solutions thanks to our many years of experience and expertise. Furthermore, we provide support in the assessment of load tests and product engineering optimization. Owing to our steadily developing expertise, this results in tailor made high-end solutions, which we produce in-house.Iron |

|

Gear Material |

20CrMnTi |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding finish by HOFLER Grinding Machines |

|

Color |

Customized |

|

Noise Test |

Bellow 65dB |

|

Warranty |

1 year |

Company Information

Quality control

Packing&Delivery

Packing Details: Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30working days upon paymen

Our Certifications

Related Product

Precision Planetary gearbox

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer | AC/DC Motor |

FAQ

1.Payment Term: TT, L/C

2.Delivery time: about 30 days from receive payment.

3.We accept customized products as per your special requirement.

4.Guidelines for the Selection:Usually we can select one machine which is suitable for you with some informations from you,such as ratio/motor speed/mounting dimension/ out torque etc.

5.If the minimum order amount is in excess of $10000, there are preferential.

Q1: What information should I tell you to confirm the product?

A:Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q2: What can i do if I don’t know which one I need?

A:Dont worry, Send as much information as you can, our team will help you find the right one you are looking for.

Q3: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

If you have another question, pls feel free to contact us as below:

Contact Us

Slip clutch type on the rotary tiller, again slight oozing of grease on the UJ, do not grease the clutch; these run dry and should be “slipped” at least once a year to prevent rusting together

Best China manufacturer & factory Two-staged Speed Reduction Helical Gearbox Reducer With high quality best price

We offer OEM service. Are you searching for a PTO water pump or PTO- driven generator? Hundreds of PTO parts from EPG mean you can find PTO shaft parts and accessories for whatever kind of equipment you’re working with. From PTO drive shafts to shield parts, we have dozens of replacement PTO parts. We stock Eurocardan parts as well as Neapco parts because those are names you can trust. Whether you need flex couplers or PTO shaft assemblies, we can help.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Model Number:

-

SRC

- Rated Power:

-

0.12—4KW

- Transmission:

-

Helical

- Our company is located in XiHu HangZhou Zhejiang Province. T Reduction:

-

Two-staged

Our solutions in the general segment are characterized by quality, reliability and power density. These products are designed for applications with medium precision requirements – in secondary axes, they can also be used for high-end applications.

- Body:

-

Aluminium

- Warranty:

-

One year and free technical support

- Coupled flange type:

-

B5 or B14

- Production standard:

-

IEC

- Customised:

-

Available for flange and shaft

- Foot mounted:

-

Available to request

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- 1 pc / carton box, several cartons for one wooden pallt

- Port

- Ningbo,Shanghai

Online Customization

Features for SRC helical gearboxes reducers,

1.Larger output torque,stable transmission with lower noise,

2.Ommibearing installation available,

3.Aluminium alloy diecast,

4.Customising available for flange or shaft

Important information for SRC helical gear speed reducers,

| Input coupling | Flange and shaft |

| Output coupling | Flange and shaft |

| Foot mounted | Available for Motovario and Bonfiglioli foot mounted specs. The letter,B in the data sheet of foot code is for Bonfiglioli and M for Motovario |

| Range of reduction ratios | 3.74—51.30 |

| Motor power coupled | 0.12—4KW |

| Version |

1.Flange coupled,shaft output,with foot mounted,marked as SRC…P

2.Shaft coupled and output,with foot mounted,marked as SRC…HS

3.Flange coupled,shaft output,no foot mounted,marked as SRCZ…P

4.Shaft coupled and output,no foot mounted,marked as SRCZ…HS

5.Flange coupled and output,no foot mounted,marked as SRCF…P

6.Shaft coupled,flange output,no foot mounted,marked as SRCF…HS

|

Outline specs for SRC01,SRC02,SRC03 and SRC04,classified to the motor power mounted with the helical gear reducers,

Installation position with motors,

Best China manufacturer & factory R Series in Line Helical Geared Motor Gearbox Speed Reducer With high quality best price

Our main products are chain , gears, sprocket, Needle Roller bearings, Cylindrical Roller Bearings, Rod end Bearings, Spherical plain bearings, Track rolWe distribute many other items that are not listed above, but are still readily available. Feel free to give us a call or send us an email. We are always ready to help.ler Bearings for Guideway, Roller Bearings, Combine Bearings for forklifts, Water Pump Bearings, SNR Auto Bearings and all kinds of Spherical Bearings.

Overview

Quick Details

- Brand Name:

-

OEM

- Model Number:

-

2020EPT

- Size:

-

17-167

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Year

Packaging & Delivery

- Packaging Details

- Standard Export Packing and Wood Pallets Packing

- Port

- SHANGHAI PORT

Online Customization

Product Introduction:

In line helical geared motor is characterized by compact structure, light weight, large torque and excellent performance. Prompt delivery within short time.

It is made of rib-reinforced rigid case and premium alloy-steel gear which is hardened by carbon penetration and grinded precisely. Stable in running, low noise, large in load, low in consumption, efficient in transmission, low in temperature rise, and long in service life.

The mounting styles are footing, flange, torque arm and so on. The output style are shaft, hollow shaft, the alpine and shrink disc are for choice.

Company Profile

l The largest manufacturer and exporter of worm gear reducers in Asia.

l Established in 1976, we transHow Can You Be Safe When Using PTO Shafts? First, make sure the shaft is shielded. This includes the driveline shield that covers the implement driveline, and the master shield which covers the universal joint and PTO stub shaft on the tractor.Maintain the shield so it can work for you. PTO driveline shields are usually mounted on bearings, so they need to be maintained. always REPLACE the shield when it is damaged or missing.Next, keep a safe distance from it when in use. Keep others away, too. How far? A distance of twice your height is a good start.Allow only those who absolutely must be in the area to be there. Keep all children away!Always pay attention to what is happening. Most PTO victims were caught by surprise.If something goes wrong — stop the machinery; take the PTO out of gear, stop the engine and set the brake. Put the keys in your pocket before working on the machinery.When stopping the machinery for any reason — end of work, lunch, repairs, or communication — take the PTO out of gear, stop the engine and set the brake.Road planers, dredges, and other equipment require power from some sort of engine in order to perform their designed function. Without a power take off, it would be necessary to add a second engine to provide the power necessary to run hydraulic pumps and other driveline attached equipment.formed from a county owned factory to private one in 1996. HANGZHOU SINO-DEUTSCH POWER TRANSMISSION EQUIPMENT CO.,LTD is our new name since 2001.

l We are the first manufacturer of reducers and gearboxes in China who was given export license since year 1993.

l “Fixedstar” brand gearboxes and reducers are the first owner of CHINA TOP BRAND and Most Famous Trade Mark for reducers.

First to achieve ISO9001 and CE Certificate among all manufacturers of gearboxes in China.

As a professional manufacturer of worm gearbox and worm gear reducers in China, we mainly produce reduction gearbox,aluminum case worm gearboxes,arc gear cylindrical worm gearboxes, worm gear reducers, in line helical gearboxes, and cyclo drive reducers, etc. These products feature rational structure, stable performance, and reliable quality, and so on. They are widely used in power, mining, metallurgy, building material, chemical, food, printing, ceramic, paper-making, tobacco, and other industries.

We have 600 workers in our factory, which covers 70,000 square meters in Hangzhou. We have been making 2,500 units of reducers everyday since 2012. We are proudly exporting 70% of our products to more than 40 countries all over the word. Our customers come from Italy, Germany, USA, Canada, Spain, UK, Mexico, Brazil, Argentina, Turkey, Singapore and other main industrial countries in the world. 30% of them are OEM made for direct manufacturers of other products.

We warmly welcome customers from other parts of the world to visit us. Seeing is believing. We are very confident that after visiting our facility, you will have confidence on our products. We have the latest automatic equipments and experienced workers to ensure the stable quality and large output. We have the most sophisticated technical and engineering team to support most demanding requirement on standard and OEM products.

Looking forward to meeting you in Hangzhou, China.