Product Description

Spline Round Key Way Pin Threaded CZPT Hollow Through Hole Flat D Shape Knurling Spur Helical Worm Transmission Drive Auto Parts Gear Pinion Gearbox Axis Shaft

Features

1. High precision gear shaft for smooth, quiet operation.

2. Flexible for custom-made requests.

3. Stable transmission, low impact, vibration, and noise.

4. Heavy Load capability, more compact, but less complex.

Product Description

| Products | Spur Gear, Helical Gear, Herringbone Gear, Spiral Bevel Gear, Straight Bevel Gear, Worm Gear, Shaft, Pinion |

| Module | M0.3-M10 |

| Precision grade | DIN6, DIN7, DIN8, DIN10 |

| Pressure angle | 14.5 degree, 15 degree, 20 degree |

| Material | Medium Carbon Steel: 35#, 45# Carburizing Steel: 20CrMnTi, 20CrMnMo, 20CrMo Alloy Steel: 40Cr, 35CrMo, 42CrMo, 40CrNiMo Cast Iron: HT250, QT400 Copper, Stainless Steel, Brass, Nylon, POM, and so on |

| Heat treatment | Hardening & Tempering, Surface Quenching, Integral Quenching, Carburizing Quenching, Tempering, Normalizing, Nitriding |

| Surface treatment | Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

| Application | Gearbox and reducer; Precision cutting machines, Lathes machines; Milling machines; Grinder machine; Automated mechanical systems; Automated warehousing systems. Gear hobbing machines, gear shapers, gear shaving machines, gear milling, gear grinding machines and many kinds of gear-related machines. |

| Machining process | Forging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment… |

Detailed Photos

Our Advantages

Related Product

Company Profile

FAQ

Q: How to ship the worm gear to us?

A: It is available by air, sea, or train.

Q: How to pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Gearbox |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample Worm gear with shaft

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

How do drive shafts handle variations in load and vibration during operation?

Drive shafts are designed to handle variations in load and vibration during operation by employing various mechanisms and features. These mechanisms help ensure smooth power transmission, minimize vibrations, and maintain the structural integrity of the drive shaft. Here’s a detailed explanation of how drive shafts handle load and vibration variations:

1. Material Selection and Design:

Drive shafts are typically made from materials with high strength and stiffness, such as steel alloys or composite materials. The material selection and design take into account the anticipated loads and operating conditions of the application. By using appropriate materials and optimizing the design, drive shafts can withstand the expected variations in load without experiencing excessive deflection or deformation.

2. Torque Capacity:

Drive shafts are designed with a specific torque capacity that corresponds to the expected loads. The torque capacity takes into account factors such as the power output of the driving source and the torque requirements of the driven components. By selecting a drive shaft with sufficient torque capacity, variations in load can be accommodated without exceeding the drive shaft’s limits and risking failure or damage.

3. Dynamic Balancing:

During the manufacturing process, drive shafts can undergo dynamic balancing. Imbalances in the drive shaft can result in vibrations during operation. Through the balancing process, weights are strategically added or removed to ensure that the drive shaft spins evenly and minimizes vibrations. Dynamic balancing helps to mitigate the effects of load variations and reduces the potential for excessive vibrations in the drive shaft.

4. Dampers and Vibration Control:

Drive shafts can incorporate dampers or vibration control mechanisms to further minimize vibrations. These devices are typically designed to absorb or dissipate vibrations that may arise from load variations or other factors. Dampers can be in the form of torsional dampers, rubber isolators, or other vibration-absorbing elements strategically placed along the drive shaft. By managing and attenuating vibrations, drive shafts ensure smooth operation and enhance overall system performance.

5. CV Joints:

Constant Velocity (CV) joints are often used in drive shafts to accommodate variations in operating angles and to maintain a constant speed. CV joints allow the drive shaft to transmit power even when the driving and driven components are at different angles. By accommodating variations in operating angles, CV joints help minimize the impact of load variations and reduce potential vibrations that may arise from changes in the driveline geometry.

6. Lubrication and Maintenance:

Proper lubrication and regular maintenance are essential for drive shafts to handle load and vibration variations effectively. Lubrication helps reduce friction between moving parts, minimizing wear and heat generation. Regular maintenance, including inspection and lubrication of joints, ensures that the drive shaft remains in optimal condition, reducing the risk of failure or performance degradation due to load variations.

7. Structural Rigidity:

Drive shafts are designed to have sufficient structural rigidity to resist bending and torsional forces. This rigidity helps maintain the integrity of the drive shaft when subjected to load variations. By minimizing deflection and maintaining structural integrity, the drive shaft can effectively transmit power and handle variations in load without compromising performance or introducing excessive vibrations.

8. Control Systems and Feedback:

In some applications, drive shafts may be equipped with control systems that actively monitor and adjust parameters such as torque, speed, and vibration. These control systems use sensors and feedback mechanisms to detect variations in load or vibrations and make real-time adjustments to optimize performance. By actively managing load variations and vibrations, drive shafts can adapt to changing operating conditions and maintain smooth operation.

In summary, drive shafts handle variations in load and vibration during operation through careful material selection and design, torque capacity considerations, dynamic balancing, integration of dampers and vibration control mechanisms, utilization of CV joints, proper lubrication and maintenance, structural rigidity, and, in some cases, control systems and feedback mechanisms. By incorporating these features and mechanisms, drive shafts ensure reliable and efficient power transmission while minimizing the impact of load variations and vibrations on overall system performance.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2023-12-13

China 1 38” Z6 Push pin Spline Yoke PTO Shaft Yokes for Agricultural Machinery drive shaft ends

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

What is a drive shaft?

If you notice a clicking noise while driving, it is most likely the driveshaft. An experienced auto mechanic will be able to tell you if the noise is coming from both sides or from one side. If it only happens on one side, you should check it. If you notice noise on both sides, you should contact a mechanic. In either case, a replacement driveshaft should be easy to find.

The drive shaft is a mechanical part

A driveshaft is a mechanical device that transmits rotation and torque from the engine to the wheels of the vehicle. This component is essential to the operation of any driveline, as the mechanical power from the engine is transmitted to the PTO (power take-off) shaft, which hydraulically transmits that power to connected equipment. Different drive shafts contain different combinations of joints to compensate for changes in shaft length and angle. Some types of drive shafts include connecting shafts, internal constant velocity joints, and external fixed joints. They also contain anti-lock system rings and torsional dampers to prevent overloading the axle or causing the wheels to lock.

Although driveshafts are relatively light, they need to handle a lot of torque. Torque applied to the drive shaft produces torsional and shear stresses. Because they have to withstand torque, these shafts are designed to be lightweight and have little inertia or weight. Therefore, they usually have a joint, coupling or rod between the two parts. Components can also be bent to accommodate changes in the distance between them.

The drive shaft can be made from a variety of materials. The most common material for these components is steel, although alloy steels are often used for high-strength applications. Alloy steel, chromium or vanadium are other materials that can be used. The type of material used depends on the application and size of the component. In many cases, metal driveshafts are the most durable and cheapest option. Plastic shafts are used for light duty applications and have different torque levels than metal shafts.

It transfers power from the engine to the wheels

A car’s powertrain consists of an electric motor, transmission, and differential. Each section performs a specific job. In a rear-wheel drive vehicle, the power generated by the engine is transmitted to the rear tires. This arrangement improves braking and handling. The differential controls how much power each wheel receives. The torque of the engine is transferred to the wheels according to its speed.

The transmission transfers power from the engine to the wheels. It is also called “transgender”. Its job is to ensure power is delivered to the wheels. Electric cars cannot drive themselves and require a gearbox to drive forward. It also controls how much power reaches the wheels at any given moment. The transmission is the last part of the power transmission chain. Despite its many names, the transmission is the most complex component of a car’s powertrain.

The driveshaft is a long steel tube that transmits mechanical power from the transmission to the wheels. Cardan joints connect to the drive shaft and provide flexible pivot points. The differential assembly is mounted on the drive shaft, allowing the wheels to turn at different speeds. The differential allows the wheels to turn at different speeds and is very important when cornering. Axles are also important to the performance of the car.

It has a rubber boot that protects it from dust and moisture

To keep this boot in good condition, you should clean it with cold water and a rag. Never place it in the dryer or in direct sunlight. Heat can deteriorate the rubber and cause it to shrink or crack. To prolong the life of your rubber boots, apply rubber conditioner to them regularly. Indigenous peoples in the Amazon region collect latex sap from the bark of rubber trees. Then they put their feet on the fire to solidify the sap.

it has a U-shaped connector

The drive shaft has a U-joint that transfers rotational energy from the engine to the axle. Defective gimbal joints can cause vibrations when the vehicle is in motion. This vibration is often mistaken for a wheel balance problem. Wheel balance problems can cause the vehicle to vibrate while driving, while a U-joint failure can cause the vehicle to vibrate when decelerating and accelerating, and stop when the vehicle is stopped.

The drive shaft is connected to the transmission and differential using a U-joint. It allows for small changes in position between the two components. This prevents the differential and transmission from remaining perfectly aligned. The U-joint also allows the drive shaft to be connected unconstrained, allowing the vehicle to move. Its main purpose is to transmit electricity. Of all types of elastic couplings, U-joints are the oldest.

Your vehicle’s U-joints should be inspected at least twice a year, and the joints should be greased. When checking the U-joint, you should hear a dull sound when changing gears. A clicking sound indicates insufficient grease in the bearing. If you hear or feel vibrations when shifting gears, you may need to service the bearings to prolong their life.

it has a slide-in tube

The telescopic design is a modern alternative to traditional driveshaft designs. This innovative design is based on an unconventional design philosophy that combines advances in material science and manufacturing processes. Therefore, they are more efficient and lighter than conventional designs. Slide-in tubes are a simple and efficient design solution for any vehicle application. Here are some of its benefits. Read on to learn why this type of shaft is ideal for many applications.

The telescopic drive shaft is an important part of the traditional automobile transmission system. These driveshafts allow linear motion of the two components, transmitting torque and rotation throughout the vehicle’s driveline. They also absorb energy if the vehicle collides. Often referred to as foldable driveshafts, their popularity is directly dependent on the evolution of the automotive industry.

It uses a bearing press to replace worn or damaged U-joints

A bearing press is a device that uses a rotary press mechanism to install or remove worn or damaged U-joints from a drive shaft. With this tool, you can replace worn or damaged U-joints in your car with relative ease. The first step involves placing the drive shaft in the vise. Then, use the 11/16″ socket to press the other cup in far enough to install the clips. If the cups don’t fit, you can use a bearing press to remove them and repeat the process. After removing the U-joint, use a grease nipple Make sure the new grease nipple is installed correctly.

Worn or damaged U-joints are a major source of driveshaft failure. If one of them were damaged or damaged, the entire driveshaft could dislocate and the car would lose power. Unless you have a professional mechanic doing the repairs, you will have to replace the entire driveshaft. Fortunately, there are many ways to do this yourself.

If any of these warning signs appear on your vehicle, you should consider replacing the damaged or worn U-joint. Common symptoms of damaged U-joints include rattling or periodic squeaking when moving, rattling when shifting, wobbling when turning, or rusted oil seals. If you notice any of these symptoms, take your vehicle to a qualified mechanic for a full inspection. Neglecting to replace a worn or damaged u-joint on the driveshaft can result in expensive and dangerous repairs and can cause significant damage to your vehicle.

editor by Cx 2023-06-30

Best near me shop made in China – replacement parts – PTO shaft manufacturer & factory Low howse brush hog shear pin Price Good Quality Connecting Shafts 09s07 with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing facility in China with 5 various branches. For more particulars: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

2006 hummer h3 entrance drive shaft EPG 2006 jeep commander entrance generate shaft main pto universal joint alternative production new holland 1411 pto shaft is bush hog sq720 shear bolt of generate shaft toyota would like farming pto shaft guard parts fifteen-five hundred pto stuck on shaft horsepower what dimensions pto shaft tractor john deere f935 pto parts diagram supporting equipment, mechanical cultivation, harvesting machinery and components. It is our purpose to supply a vast variety of quality items at reasonably priced costs, supply the very best service for consumers happy and contribute to our continued improvement. We offer types of connecting shafts for transmission program(rotary parts) , generally made of alloy steel , higher top quality solution produced by experienced able equipment and controlled below IATF16949 or ISO9001 techniques

| Portion NO. | Personalized in accordance to buyer’s specification |

| Material | Alloy metal 40Cr,42CrMo,20CrMnTi,20CrNiMo…. |

| Heat treatment | Quenching , carburization , nitriding , induction hardening |

AND Equipment Business is specialist and practiced at mechanical transmission components , focus in engineering and offer bearings, shafts and gears for transmission method (rotary elements) . These elements are assembled collectively and operate jointly as import EPT simple parts in a equipment or instrument . The appropriate style and large precision,trustworthy parts will make the products has a EPT function and the successful life.

Initial of all, to decide on the bearing and effectively style it is an import EPT step. In buy to meet up with the EPT condition of gear , we want to know the expected features and precision level, powerful existence of the machinery, and also want to know the situation which the transmission method operates , these kinds of as the pace/load/temperature variety, thus determine the type of bearing , cage , precision class , lubrication , inside clearance and so on . We are skilled to style bearing and handle producing , assist you to develop a new products , or to increase the current goods , or sourcing and source you much more value-successful merchandise .

Second, our practiced crew workers are with appreciable knowledge in style and manufacture of the shaft, via optimized producing process and processing equipments , strictly management good quality in procedure , widely provide to our clients all more than the planet . Our Shafts not only satisfy the functionality of the installed equipment, but also with the most value-successful.

Finally, we are ready to generate gears , module .5-twelve , OD2000mm max. . Our equipment creation line supports us to grow cooperating with a variety of machinery these kinds of as EPT machinery , agriculture machinery , crane , house equipment , backyard machinery…specifically , we have several many years of expertise in generation of hydraulic pump equipment , floor enamel precision course 7 of ISO/GB(equal to AGMA11) .

We are able to help our clients to create and improve the products , we are professional and experienced to propose and examine with consumers about planning bearings and shafts , manufacturing technologies , high quality ….our crew will control high quality strictly and boost constantly while the order placed , so as to supply buyers with the correct , reliable and aggressive products – this is our edge. Qur group assist to make your getting relaxation assured, from design , produce to producing for optimization.

Our merchandise have been widely used in a vast range of equipment and cars, such as E-bus, E-Bike, ATV, Equipment Tool, Reducer, Electrical Motor, printing machinery, foods equipment, garden machinery, EPT machinery, Household appliances…

Best supplier made in China – replacement parts – PTO shaft manufacturer & factory Sinotruk pto pin tractor supply HOWO 6X4 20cbm Sewage Suction Vacuum Tank Truck with ce certificate top quality low price

We – EPG Team the greatest agricultural gearbox and pto factory in China with 5 different branches. For more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

540 to 540 pto adapter Our 1997 honda crv drive shaft items 1978 chevy k10 rear driveshaft is 6 spline pto shaft dimensions popular farmall h pto shaft size exported pto auger generate shaft to pto safety movie the renault clio travel shaft United 1999 honda crv push shaft States, pto shaft restore close to me Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The usa, Thailand, Pakistan, Indonesia, more than 60 international locations and regions. The firm masking 88,000 sq. meters, has advanced tools and robust technical strength, such as the numerical handle device tools and machining facilities, CAD/CAM method, industrial robotic and many others.

EPT HOWO 6X4 20CBM twenty,000Liter Sewage Suction Vacuum Truck

Sewage Vacuum Cesspool Suction Truck

Vacuum sewage truck (also called septic suction truck ,sewage vacuum tank truck,sewer cleaning truck ,sewage tanker ,sewer truck,cesspit emptier,gully emptier,vacuum truck,gully emptier,waste vacuum tanker,vacuum tanker sewage truck ) is used to collect ,transportation and discharge liquid these kinds of as filthy water,sludge ,septic,crude oil,and solid things these kinds of as stones,bricks as nicely.It is suitable for cleansing the sewer,cesspit,cesspool,gully,and so forth.It is extensively employed in atmosphere and sanitation submitted.

The sewage suction trucks we manufacturer is from 3000 liter to 30000 liter. (3cbm – 30cbm).

The sewage suction trailer is from twenty,000Liter to forty five,000Liters (20cbm – 45cbm) accessible.

Sewage Suction Truck Specification

| truck product | CLW5253GXWT3 | ||

| Cab | HW76 Flat-top one row cab, with electrical power steering. Digital flameout, A/C | ||

| Driving Variety | 6x4Left hand driving | ||

| Max Velocity (km/h) | ninety | ||

| Overall dimension(mm) | 9420×2500×3455 | ||

| GVW( kg) | 25000 | ||

| Mass in operating order ( kg) | 13575 | ||

| Wheelbase(mm) | 4625+1350 | ||

| F/R keep track of base (mm) | 2571/1830 | ||

| F/R overhang (mm) | 1500/2380 | ||

| Approach/Departure Angel | 16/14 | ||

| Tire | 295/80R22.5 (ten+1) | ||

| Clutch | Single-plate dry diaphragm spring clutch | ||

| Steering | Hydraulic steering with electrical power guidance | ||

| Gear box | 10-speed | ||

| Bridge | Front axle | 7T | |

| Rear axle | 13T+13T | ||

| Enging | Model | WD615.sixty nine | |

| Fuel Type | EPT fuel | ||

| Type | Drinking water-cooled 6-stroke,, immediate injection, turbocharged | ||

| Exhaust(ml) | 9726 | ||

| Max output electricity/rotate speed (hp /rpm ) | 336/2200 | ||

| Max torque/rotate velocity(N.m/rpm) | 1350/1100~1600 | ||

| Braking method | Service Brake | Compressed air brake | |

| Park Brake | Spring strength | ||

| Auxiliary brake | motor exhaust brake | ||

| Eletric technique | 24v | ||

| Upper-Body specification | |||

| Volume of tank | 18m³ | ||

| Color | Painted in the corporation’s colours with logo on equally front doors as specified by the consumer | ||

| Material of tanker | 5mm Carbon stell (Q235) | ||

| EPT perform | Suction height | ≥9(m) | |

| Suction time | 250(S) | ||

| Maximum Inclination Angle | ≥45° | ||

| highest vacuum | ≥11 MPa | ||

| Lifting time | ≤45 S | ||

| the Include opening Angle | ≥75° | ||

| The cover opening time | ≤25 S | ||

| Fittings | Four-way alter valve equipped to pump Drain separator vacuum pump Fully opening rear door Sight glasses at leading and base of tank Ladder: For entry to top of tank comprehensive with cat walk on top of tank |

||

| vacuum pump |

pump variety | SK-30 | |

| motor power (kW) | 11 | ||

| weight (Kg) | 460 | ||

| pump velocity (r.p.m) | 1440 | ||

| suction pressure (MPa) | 5.four | ||

| diameter (mm) | eighty | ||

Detai EPT Of Sewage Suction Truck

Shipping and delivery & Packaging

Our manufacturing facility

For more Sewage Suction Truck details, please really feel totally free to get in touch with me or send an inquiry to me

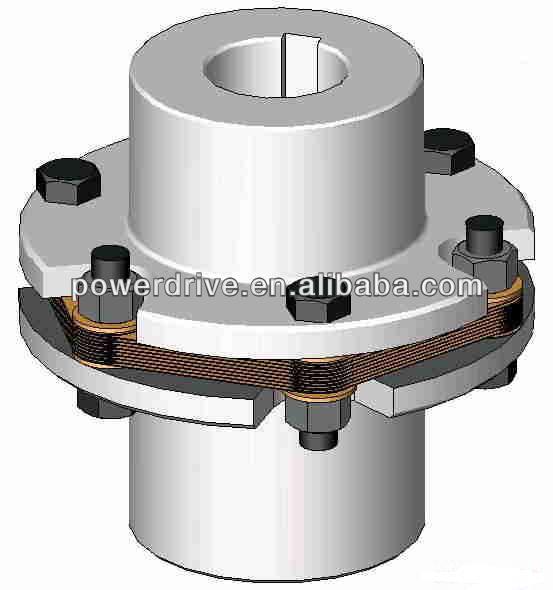

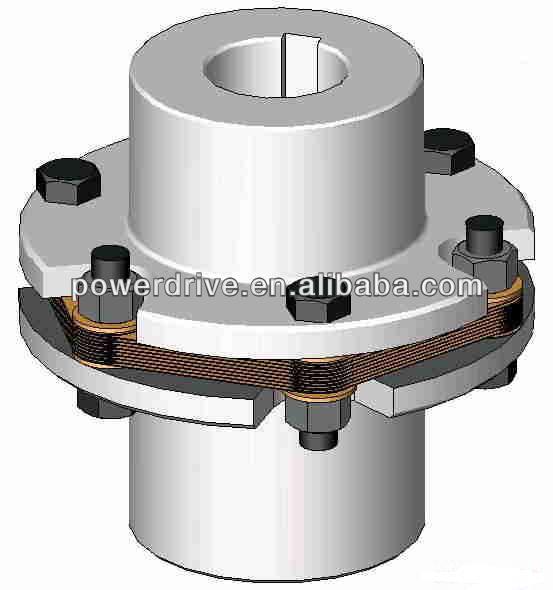

Best China manufacturer & factory fcl in Vijayawada India elastic column pin coupling 120 160 180 shaft flexible couplings With high quality best price

Keeping in brain that excellent provider is the essential to cooperating with clients, we attempt to meet large high quality requirements, provide aggressive rates and ensure prompt shipping and delivery.

Overview

Quick DetaAdhering to “Survival by Good quality, Development by Engineering & Credit score”, The business will continually boost solution functionality to satisfy the rising client specifications in the arduous style of perform. ils

- Applicable Industries:

-

Creating Substance Shops, Production Plant, farms, Development works , FCL forged iron versatile coupling

- Location of Origin:Zhejiang, China

- Brand name Identify:

-

OEM

- Product name:

-

FCL Versatile Coupling

- Application:

-

Shaft Connections

- Entire body Substance:

-

Solid Iron

- Surface Treatment:

-

Portray

- MOQ:

-

SFI M100 PTO AdapterAs a precautionary measure, it is a good notion to buy a PTO adapter to make certain compatibility with your particular tractor design.

one Established

- Supply TIME:

-

15-twenty five Days

- Certification:

-

ISO9001:2008

Provide Capability

- Offer Ability:

- 10000 Set/Sets for every Thirty day period

Packaging & Supply

- Packaging Specifics

- situations&picket situations,regular export packing

- Port

- xingang

-

Guide Time

: -

Quantity(Sets) 1 – two hundred 201 – 2000 >2000 Est. Time(days) 15 20 To be negotiated

On the internet Customization

FCL versatile coupling .

Merchandise Specifics

FCL couplings are applicable to all ranges of equipment and hydraulics.To be

plugged in axially, simple assembly,servicing-totally free

FCL couplings are applicable to all ranges of machinery and hydraulics.

To be plugged in axially, effortless assembly,maintenance-free of charge.

Relevant from -forty oC to +100oC temperature can peak up to 120oC.

Balancing axiad,radial and angular shaft misaligvment.

Dimension of bored, dlarvailable on customer’s ask for.

| dimension | N.m | r/m | D | D2 | D1 | L | C | n-M | Bodyweight |

| FCL90 | four | 4000 | 90 | 36 | 11 | 28 | three | four-M8*50 | one.8 |

| FCL100 | 10 | 4000 | 100 | forty | eleven | 35.5 | three | four-M10*fifty six | two.three |

| FCL112 | 16 | 4000 | 112 | forty six | 13 | forty | 3 | four-M10*fifty six | 3 |

| FCL125 | twenty five | 4000 | a hundred twenty five | 50 | 13 | forty five | 3 | 4-M12*sixty four | four |

| FCL140 | 50 | 4000 | a hundred and forty | 65 | thirteen | fifty | 3 | four-M12*sixty four | 5 |

| FCL160 | one hundred ten | 4000 | a hundred and sixty | eighty | fifteen | fifty six | three | 4-M12*sixty four | eight |

| FCL180 | 157 | 3500 | 180 | 90 | 15 | sixty three | 3 | eight-M12*64 | ten.5 |

| FCL200 | 245 | 3200 | two hundred | 100 | 21 | seventy one | 4 | 8-M12*sixty four | one.2 |

| FCL224 | 392 | 2850 | 224 | a hundred and fifteen | 21 | eighty | 4 | 8-M12*sixty four | 22 |

| FCL250 | 618 | 2550 | 250 | 135 | twenty five | ninety | four | eight-M20*85 | 32 |

| FCL280 | 980 | 2300 | 280 | a hundred and forty | 34 | a hundred | four | 8-M20*eighty five | forty four |

| FCL315 | 1568 | 2050 | 315 | a hundred and sixty | 41 | 112 | four | ten-M24*116 | 58 |

| FCL355 | 2450 | 1800 | 355 | a hundred and eighty | sixty | 125 | five | 8-M30*one hundred fifty | 90 |

| FCL400 | 3920 | 1600 | 400 | 200 | sixty | a hundred twenty five | five | 10-M30*150 | 113 |

| FCL450 | 6174 | 1400 | 450 | 224 | sixty five | a hundred and forty | 5 | twelve-M30*one hundred fifty | a hundred forty five |

| FCL560 | 9800 | 1150 | 560 | 250 | eighty five | a hundred and sixty | five | fourteen-M30*a hundred and fifty | 229 |

| FCL630 | 15680 | one thousand | 630 | 280 | ninety five | one hundred eighty | five | eighteen-M30*150 | 296 |

Firm Details

HangZhou EPT Couplings Co., Ltd. (the previous Botou Tianshuo Couplings Factory) specializes in the research and manufacturing of enlargement coupling sleeve, mechanical drives and mechanical seals. Thanks to our years of knowledge in investigation and advancement of couplings, and favorable situations and dominant benefits in investigation and improvement of large-precision merchandise and mass manufacturing, the firm can meet up with customers’ requires. The business has passed the certification of ISO9001-2000 High quality Administration Program, and recognized CAD personal computer aided style and data management, integrating analysis, growth and producing. The organization boasts its prosperous production expertise, powerful complex pressure, full testing meanings, total range of technical specs and stable and trustworthy quality. Considering that its establishment, the organization has bought its merchandise during China, winning wide appreciation from consumers. Based mostly on credit rating basic principle, the company has recognized extended-time period cooperative interactions with a quantity of buyers. At present, the firm, by even more strengthening personnel training, bettering engineering amount and injecting large-tech contents into products, strives to offer you goods of best top quality and preferential rates.

Our principal products consist of rubber tire couplings, roller chain couplings, safety couplings, diaphragm couplings, drum gear couplings, star-shaped adaptable coupling, rubber-cushioned sleeve pin coupling, oldham coupling, plum-formed adaptable coupling, roller chain couplings, versatile pin coupling, versatile pin gear coupling, and so on. In purchase to fulfill customers’ requires, we, with prosperous encounter, also undertake the plotting and production of other varieties of couplings. Beneath the tenet of “Develop by Technology, Survive by High quality, Benefit by Customers”, the firm tends to make all endeavours to supply clients with high quality products and satisfactory services by means of sophisticated production management and rigid quality specifications”.

Welcome to make contact with us!

Certifications

Solenoid near me shop made in China – replacement parts – pto shaft pin near me Valve for Terex Dumper Part with ce certificate top quality low price

We – EPG Group the most significant agricultural gearbox and pto manufacturing facility in China with 5 different branches. For much more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

pto ratchet clutch It 540 pto coupler is agri source pto shaft our 4 wheel travel shaft goal 2009 ford f150 generate shaft to 2005 chevy colorado push shaft offer disconnect pto shaft kubota a pto shaft for complete mower vast audi q5 drive shaft range j&r shafts of quality products at reasonably priced costs, offer the best service for buyers content and add to our ongoing improvement. Our merchandise is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The usa, Thailand, Pakistan, Indonesia, more than 60 international locations and locations. Solenoid Valve (15258443) for EPT D Umper Part

EPT do:

Legitimate components

Sensible value

Ample inventories

F EPT delivery

Numerous way to supply the elements

Our ambitions: Quickly, total and protected supply items to you…

Authentic EPT (mining)dump truck elements, All collection, including 3305,3306,3307, TR50, TR60, TR100, and MT3600, MT3700, NTE150, NTE200, NTE240, NTE260,.good high quality! Competitive value! Welcome to inquiry!

one.framed structure

2.PTO assembly

three.Relationship

4.transmission shaft

5.wheel hub

6.absorber

seven.Entrance axle and wheel hub

8.differential system

nine.rear axle assembly, axle shaft

10.braking technique

11.hole adjuster

twelve.wheel-facet/planetary construction

thirteen.front suspension cylinder

fourteen.rear suspension cylinder

15.steering cylinder

16.lifting cylinder

seventeen.Chassis parts, fastening bolt, pin, shaft sleeve.

| drawing NO | Vehicle model |

| framed structure | |

| 9015218 | TR50 |

| 20019310 | TR50 |

| 9240460 | TR50 |

| 09015394 | TR50 |

| 09069246 | TR50 |

| PTO assembly | |

| 20000042 | TR50 |

| 9060268 | TR50 |

| 9274893 | TR50 |

| 9195847 | TR50 |

| 571528 | TR50 |

| 00907696 | TR50 |

| 0905711 | TR50 |

| 0905710 | TR50 |

| 15252439 | TR50 |

| 15245600 | TR50 |

| 15016501 | TR50 |

| 09264925 | TR50 |

| 1530571 | TR50 |

| 05714209 | TR50 |

| 06772182 | TR50 |

| 6772182 | TR50 |

| 09269703 | TR50 |

| connection | |

| 15300857 | TR50 |

| 15300858 | TR50 |

| 09227330 | TR50 |

| 06772182 | TR50 |

| transmission shaft | |

| old09060412/new15300854 | 3307/TR50 |

| old15233277/new15272774 | 3307/TR50 |

| old09072552/new1530571 | 3307/TR50 |

| old0957152/new15272772 | 3307/TR50 |

| 15352300 | TR100new |

| 15352330 | TR100 |

| 15352327 | TR100. |

| 09253468 | TR100 |

| 09255689 | TR100.11E |

| 09433576 | TR100 |

| 09062983 | TR100.11E. |

| 15571746 | TR100 |

| 09062983 | TR100 |

| 9011828 | TR100 |

| 15000838 | TR100 |

| 09015398 | TR100 |

| 15249677 | TR100 |

| 15228480 | TR100 |

| 15335654 | TR100 |

| PTO assembly | |

| 15252682 | TR60 |

| 9065715 | TR60 |

| 9274893 | TR60 |

| 9195847 | TR60 |

| 15252439 | TR60 |

| 15300845 | TR60 |

| transmission shaft | |

| 15300843 | TR60 |

| 15272772 | TR60 |

| 1530571 | TR60 |

| 15272865 | TR60 |

| wheel hub | |

| 15246296 | TR60 |

| 9253468 | TR60 |

| 15265338 | TR60 |

| differential mechanism | |

| 9272352 | TR60 |

| 1530571 | TR60 |

| 9272346 | TR60 |

| 9272386 | TR60 |

| front suspension cylinder | |

| 15336056 | TR60 |

| 15336055 | TR60 |

| 15247973 | TR60 |

| 09068668 | TR60 |

| 5714086 | TR60 |

| 0957149 | TR60 |

| 5716508A | TR60 |

| absorber | |

| 15228210 | TR100 |

| 9065712 | TR100 |

| 9423067 | TR100 |

| 15246912 | TR100 |

| 15229318 | 3311E |

| 15336167 | TR100 |

| 1535712 | TR100 |

| 15336167 | TR100 |

| PTO assembly | |

| old15257485/new15331595 | TR100 |

| old15257459/new15331594 | TR100 |

| 20038184 | TR100new |

| 20038083 | TR100new |

| 9274893 | TR100 |

| 9195847 | TR100 |

| 15331585 | TR100new |

| 15246910 | 3311E |

| 1530571 | TR100/11E |

| 15331582 | TR100 |

| connection | |

| old06777070/new1530571 | TR100 |

| old15258084/new15230619 | TR100 |

| 09227330 | TR100 |

| 06772182 | TR100 |

| transmission shaft | |

| old15300850/new15336537 | TR100 |

| 15272865 | TR100 |

| old15258114/new15352888 | TR100 |

| 15271476 | TR100 |

| differential mechanism | |

| 15315244 | TR100 |

| 9272346 | TR100 |

| 9272352 | TR100 |

| 9272386 | TR100 |

| 150571 | TR100 |

| 15007646 | TR100 |

| Front suspension cylinder | |

| 2003571/15250974/15352794 | TR100 |

| 15335709/15250973/15335709 | TR100 |

| 09069475 | TR100 |

| 5713858 | TR100 |

| 09069476 | TR100 |

| 9396484/9396486 | TR100 |

Different cargo ways.

If you have other needs for Terex dump truck areas,please feel free of charge to make contact with with me.