Product Description

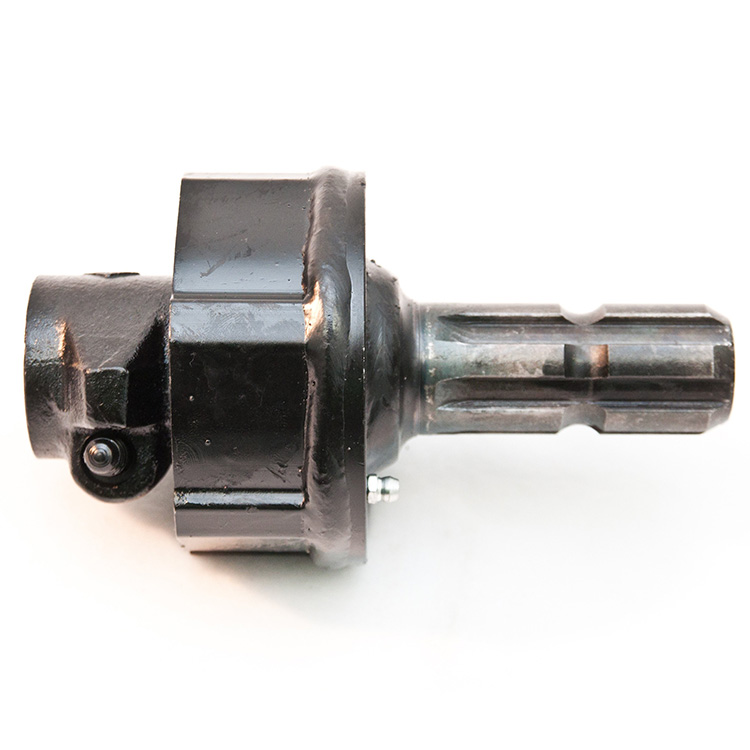

Tractor Pto Driveshaft Driveline Factory Hollow Spline Cardan Adapter Universal Joint Yoke Flexible Front Prop Rear CV Axle Propeller Automobile Drive Shaft

Product Description

Agricultural truck universal joint steering

PTO Shaft

| Function of PTO Shaft | Drive Shaft Parts & Power Transmission |

| Usage of PTO Shaft | Kinds of Tractors & Farm Implements |

| Yoke Types for PTO Shaft | Double push pin, Bolt pins, Split pins, Pushpin, Quick release, Ball attachment, Collar….. |

| Processing Of Yoke | Forging |

| PTO Shaft Plastic Cover | YW; BW; YS; BS; Etc |

| Colors of PTO Shaft | Green; Orange; Yellow; Black Ect. |

| PTO Shaft Series | T1-T10; L1-L6;S6-S10;10HP-150HP with SA,RA,SB,SFF,WA,CV Etc |

| Tube Types for PTO Shaft | Lemon, Triangular, Star, Square, Hexangular, Spline, Special Ect |

| Processing Of Tube | Cold drawn |

| Spline Types for PTO Shaft | 1 1/8″ Z6;1 3/8″ Z6; 1 3/8″ Z21 ;1 3/4″ Z20; 1 3/4″ Z6; 8-38*32*6 8-42*36*7; 8-48*42*8; |

We also sell accessories for the pto shaft, including :

Yoke: CV socket yoke, CV weld yoke, flange yoke, end yoke, weld yoke, slip yoke

CV center housing, tube, spline, CV socket flange, u-joint, dust cap

Light vehicle drive line

Our products can be used for transmission shafts of the following brands

Toyota, Mitsubishi, Nissan, Isu zu, Suzuki, Dafa, Honda, Hyundai, Mazda, Fiat, Re nault, Kia, Dacia, Ford. Dodge, Land Rover, Peu geot, Volkswagen Audi, BMW Benz Volvo, Russian models

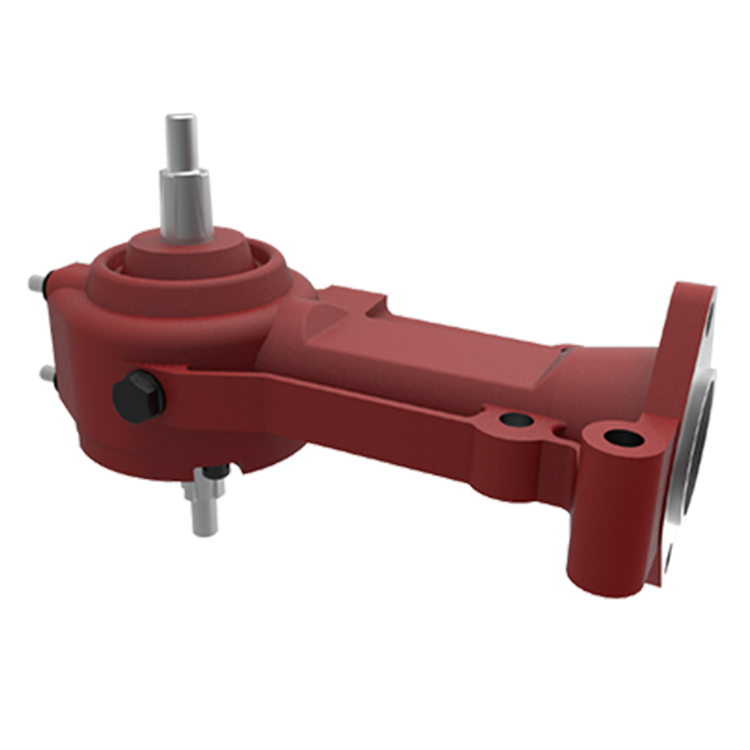

Gear shaft

Company Profile

Related Products

Application:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 38/Piece

1 Piece(Min.Order) | |

|---|

How do drivelines ensure optimal power transfer while minimizing energy losses?

Drivelines play a crucial role in ensuring optimal power transfer from the engine to the wheels while minimizing energy losses. The design and components of the driveline system are carefully engineered to maximize efficiency and minimize power wastage. Here are some key factors that contribute to achieving optimal power transfer and minimizing energy losses within a driveline:

1. Efficient Power Transmission:

Drivelines utilize various components, such as transmissions, clutches, and torque converters, to transmit power from the engine to the wheels. These components are designed to minimize energy losses by reducing friction, improving gear mesh efficiency, and optimizing torque transfer. For example, using low-friction materials, such as roller bearings, and employing advanced gear designs, like helical or hypoid gears, can help reduce power losses due to friction and gear meshing.

2. Gear Ratio Optimization:

The selection of appropriate gear ratios is essential for achieving optimal power transfer. By choosing gear ratios that match the engine’s power characteristics and the vehicle’s driving conditions, the driveline can efficiently convert and transmit power to the wheels. Optimized gear ratios ensure that the engine operates within its optimal RPM range, reducing unnecessary power losses and improving overall efficiency.

3. Limited Slip Differentials:

In driveline systems with multiple driven wheels (such as all-wheel drive or four-wheel drive), limited slip differentials (LSDs) are often employed to distribute power between the wheels. LSDs allow for better traction by transferring torque to the wheels with more grip while minimizing energy losses. By allowing some degree of differential wheel speed, LSDs ensure power is efficiently transmitted to the wheels that can utilize it most effectively.

4. Hybrid and Electric Drivetrains:

In hybrid and electric drivetrains, driveline systems are designed to optimize power transfer and minimize energy losses specific to the characteristics of electric motors and energy storage systems. These drivetrains often utilize sophisticated power electronics, regenerative braking systems, and advanced control algorithms to efficiently manage power flow and energy regeneration, resulting in improved overall system efficiency.

5. Aerodynamic Considerations:

Drivelines can also contribute to optimal power transfer by considering aerodynamic factors. By minimizing air resistance through streamlined vehicle designs, efficient cooling systems, and appropriate underbody airflow management, drivelines help reduce the power required to overcome aerodynamic drag. This, in turn, improves overall driveline efficiency and minimizes energy losses.

6. Advanced Control Systems:

The integration of advanced control systems within drivelines allows for optimized power transfer and efficient operation. Electronic control units (ECUs) monitor various parameters such as throttle position, vehicle speed, and driving conditions to adjust power distribution, manage gear shifts, and optimize torque delivery. By continuously adapting to real-time conditions, these control systems help maximize power transfer efficiency and minimize energy losses.

7. Material Selection and Weight Reduction:

The choice of materials and weight reduction strategies in driveline components contribute to minimizing energy losses. Lightweight materials, such as aluminum or composites, reduce the overall weight of the driveline system, resulting in reduced inertia and lower power requirements. Additionally, reducing the weight of rotating components, such as driveshafts or flywheels, helps improve driveline efficiency by minimizing energy losses associated with rotational inertia.

8. Regular Maintenance and Lubrication:

Proper maintenance and lubrication of driveline components are essential for minimizing energy losses. Regular maintenance ensures that driveline components, such as bearings and gears, are in optimal condition, minimizing frictional losses. Additionally, using high-quality lubricants and maintaining appropriate lubrication levels reduces friction and wear, improving driveline efficiency.

By incorporating these design considerations and engineering techniques, drivelines can achieve optimal power transfer while minimizing energy losses. This leads to improved overall efficiency, enhanced fuel economy, and reduced environmental impact.

How do drivelines enhance the performance of different types of vehicles?

Drivelines significantly contribute to enhancing the performance of different types of vehicles by optimizing power delivery, improving traction, and tailoring the driving characteristics to suit specific needs. Here’s a detailed explanation of how drivelines enhance performance in various vehicle types:

1. Passenger Cars:

In passenger cars, driveline configurations, such as front-wheel drive (FWD), rear-wheel drive (RWD), and all-wheel drive (AWD), play a crucial role in performance. Here’s how drivelines enhance performance in passenger cars:

- FWD: Front-wheel drive systems provide better traction and stability, particularly in adverse weather conditions. FWD drivelines distribute weight more evenly over the front wheels, resulting in improved grip during acceleration and cornering.

- RWD: Rear-wheel drive drivelines offer better weight distribution, allowing for improved handling and balanced performance. RWD vehicles typically exhibit better acceleration and a more engaging driving experience, especially in performance-oriented cars.

- AWD: All-wheel drive drivelines deliver power to all four wheels, improving traction and stability in various driving conditions. AWD systems enhance performance by maximizing grip and providing optimal power distribution between the front and rear wheels.

2. Sports Cars and Performance Vehicles:

Driveline systems in sports cars and performance vehicles are designed to enhance acceleration, handling, and overall driving dynamics. Key features include:

- Rear-Wheel Drive (RWD): RWD drivelines are often favored in sports cars for their ability to deliver power to the rear wheels, resulting in better weight transfer during acceleration and improved handling characteristics.

- Performance-oriented AWD: Some high-performance vehicles employ advanced AWD systems that can variably distribute torque between the front and rear wheels. These systems enhance traction, stability, and cornering capabilities, allowing for superior performance on both dry and slippery surfaces.

- Torque Vectoring: Certain driveline systems incorporate torque vectoring technology, which actively varies the torque distribution between wheels. This enables precise control during cornering, reducing understeer and enhancing agility and stability.

3. Off-Road Vehicles:

Drivelines in off-road vehicles are designed to provide exceptional traction, durability, and maneuverability in challenging terrains. Key features include:

- Four-Wheel Drive (4WD) and All-Wheel Drive (AWD): 4WD and AWD drivelines are commonly used in off-road vehicles to improve traction on uneven surfaces. These drivelines distribute power to all wheels, allowing for better grip and enhanced off-road capability.

- Differential Locks: Off-road drivelines often incorporate differential locks that can be engaged to lock the wheels on an axle together. This feature ensures that power is evenly distributed to all wheels, maximizing traction and overcoming challenging obstacles.

- High Ground Clearance: Drivelines in off-road vehicles are designed to accommodate higher ground clearance, allowing for improved approach, departure, and breakover angles. This design feature enhances the vehicle’s ability to navigate over rough terrain without damaging the driveline components.

4. Trucks and Commercial Vehicles:

Drivelines in trucks and commercial vehicles are engineered to provide high torque delivery, durability, and efficiency. Key features include:

- High Torque Handling: Drivelines in trucks and commercial vehicles are designed to handle high torque outputs from powerful engines, enabling efficient towing, hauling, and overall performance.

- Transmission Options: Drivelines in trucks often feature transmissions with multiple gear ratios, allowing drivers to select the appropriate gear for different load conditions. This enhances performance, fuel efficiency, and overall drivability.

- Efficient Power Transfer: Drivelines in commercial vehicles focus on maximizing power transfer efficiency, minimizing energy losses, and optimizing fuel economy. This is achieved through the use of efficient transmission designs, low-friction components, and advanced control systems.

5. Electric and Hybrid Vehicles:

Drivelines in electric and hybrid vehicles play a crucial role in delivering power from the electric motor(s) to the wheels. Key features include:

- Instant Torque: Electric drivelines offer instant torque delivery, providing quick acceleration andresponsive performance. This enhances the driving experience and allows for swift overtaking and merging.

- Regenerative Braking: Electric and hybrid drivelines can incorporate regenerative braking systems, which convert kinetic energy during braking into electrical energy. This improves overall efficiency and extends the vehicle’s range.

- Multi-Motor Systems: Some electric and hybrid drivelines utilize multiple motors to drive different axles or wheels independently. This enables advanced torque vectoring and enhances handling, stability, and traction control.

These are just a few examples of how drivelines enhance the performance of different types of vehicles. Driveline configurations, technologies, and engineering considerations are tailored to each vehicle type, optimizing power delivery, handling, traction, and other performance characteristics specific to their intended use and market segment.

What benefits do drivelines offer for different types of vehicles and equipment?

Drivelines offer several benefits for different types of vehicles and equipment across various industries. They play a critical role in power transmission, mobility, efficiency, and overall performance. Here’s a detailed explanation of the benefits drivelines offer for different types of vehicles and equipment:

1. Power Transmission: Drivelines are designed to efficiently transmit power from the engine or power source to the driven components, such as wheels, tracks, implements, or machinery. They ensure the smooth transfer of torque, allowing vehicles and equipment to generate the necessary power for propulsion, lifting, hauling, or other tasks. By effectively transmitting power, drivelines maximize the performance and productivity of vehicles and equipment.

2. Mobility and Maneuverability: Drivelines enable vehicles and equipment to achieve mobility and maneuverability across various terrains and working conditions. By transmitting power to the wheels or tracks, drivelines provide the necessary traction and control to overcome obstacles, navigate uneven surfaces, and operate in challenging environments. They contribute to the overall stability, handling, and agility of vehicles and equipment, allowing them to move efficiently and safely.

3. Versatility and Adaptability: Drivelines offer versatility and adaptability for different types of vehicles and equipment. They can be designed and configured to meet specific requirements, such as front-wheel drive, rear-wheel drive, four-wheel drive, or all-wheel drive systems. This flexibility allows vehicles and equipment to adapt to various operating conditions, including normal roads, off-road terrains, agricultural fields, construction sites, or industrial facilities. Drivelines also accommodate different power sources, such as internal combustion engines, electric motors, or hybrid systems, enhancing the adaptability of vehicles and equipment.

4. Efficiency and Fuel Economy: Drivelines contribute to efficiency and fuel economy in vehicles and equipment. They optimize power transmission by utilizing appropriate gear ratios, minimizing energy losses, and improving overall system efficiency. Drivelines with advanced technologies, such as continuously variable transmissions (CVTs) or automated manual transmissions (AMTs), can further enhance efficiency by continuously adjusting gear ratios based on load and speed conditions. Efficient driveline systems help reduce fuel consumption, lower emissions, and maximize the operational range of vehicles and equipment.

5. Load Carrying Capacity: Drivelines are designed to handle and transmit high torque and power, enabling vehicles and equipment to carry heavy loads. They incorporate robust components, such as heavy-duty axles, reinforced drive shafts, and durable differentials, to withstand the demands of load-bearing applications. Drivelines ensure the reliable transmission of power, allowing vehicles and equipment to transport materials, tow trailers, or carry payloads efficiently and safely.

6. Safety and Control: Drivelines contribute to safety and control in vehicles and equipment. They enable precise control over acceleration, deceleration, and speed, enhancing driver or operator confidence and maneuverability. Drivelines with features like traction control systems, limited-slip differentials, or electronic stability control provide additional safety measures by improving traction, stability, and handling in challenging road or operating conditions. By ensuring optimal power distribution and control, drivelines enhance the overall safety and stability of vehicles and equipment.

7. Durability and Reliability: Drivelines are built to withstand harsh operating conditions and provide long-term durability and reliability. They are engineered with high-quality materials, precise manufacturing processes, and advanced technologies to ensure the driveline components can endure the stresses of power transmission. Well-designed drivelines require minimal maintenance, reducing downtime and enhancing the overall reliability of vehicles and equipment.

8. Specialized Functionality: Drivelines offer specialized functionality for specific types of vehicles and equipment. For example, in off-road vehicles or heavy-duty construction equipment, drivelines with features like differential locks, torque vectoring, or adjustable suspension systems provide enhanced traction, stability, and control. In agricultural machinery, drivelines with power take-off (PTO) units enable the connection of various implements for specific tasks like plowing, seeding, or harvesting. Such specialized driveline features enhance the performance and versatility of vehicles and equipment in their respective applications.

In summary, drivelines provide numerous benefits for different types of vehicles and equipment. They ensure efficient power transmission, facilitate mobility and maneuverability, offer versatility and adaptability, contribute to efficiency and fuel economy, handle heavy loads, enhance safety and control, provide durability and reliability, and offer specialized functionality. By incorporating well-designed drivelines, manufacturers can optimize the performance, productivity, and overall functionality of vehicles and equipment across various industries.

editor by CX 2024-05-07

China high quality Harvester Farm Harrow Tractor Pto Drive Shaft and Power Tiller Cardan Shaft for Agricultural Machinery Spare Parts

Product Description

Harvester Farm Harrow Tractor Pto Drive Shaft and Power Tiller Cardan Shaft for Agricultural Machinery Spare Parts

Product Description

A Power Take-Off shaft (PTO shaft) is a mechanical device utilized to transmit power from a tractor or other power source to an attached implement, such as a mower, tiller, or baler. Typically situated at the rear of the tractor, the PTO shaft is driven by the tractor’s engine through the transmission.

The primary purpose of the PTO shaft is to supply a rotating power source to the implement, enabling it to carry out its intended function. To connect the implement to the PTO shaft, a universal joint is employed, allowing for movement between the tractor and the implement while maintaining a consistent power transfer.

Here is our advantages when compare to similar products from China:

1.Forged yokes make PTO shafts strong enough for usage and working;

2.Internal sizes standard to confirm installation smooth;

3.CE and ISO certificates to guarantee to quality of our goods;

4.Strong and professional package to confirm the good situation when you receive the goods.

Product Specifications

Packaging & Shipping

Company Profile

HangZhou Hanon Technology Co.,ltd is a modern enterprise specilizing in the development,production,sales and services of Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gearpump and motor etc..

We adhere to the principle of ” High Quality, Customers’Satisfaction”, using advanced technology and equipments to ensure all the technical standards of transmission .We follow the principle of people first , trying our best to set up a pleasant surroundings and platform of performance for each employee. So everyone can be self-consciously active to join Hanon Machinery.

FAQ

1.What’re your main products?

we currently product Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gear pump and motor.You can check the specifications for above product on our website and you can email us to recommend needed product per your specification too.

2.What’s the lead time for a regular order?

Generally speaking, our regular standard product will need 30-45days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

3.What’s your warranty terms?

One year.

4.Can you send me a price list?

For all of our product, they are customized based on different requirements like length, ratio,voltage,and power etc. The price also varies according to annual quantity. So it’s really difficult for us to provide a price list. If you can share your detailed requirements and annual quantity, we’ll see what offer we can provide.

5.What’s the payment term?

When we quote for you,we will confirm with you the way of transaction,FOB,CIFetc.<br> For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T.

6.How to deliver the goods to us?

Usually we will ship the goods to you by sea.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Agricultural Spare Part, Agricultural Spare Part |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Agricultural Machinery,Farm Tractor, Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Agricultural Machinery, Farm Tractor |

| Material: | Carbon Steel, 45cr Steel, Carbon Steel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there any limitations or disadvantages associated with drive shafts?

While drive shafts are widely used and offer several advantages, they also have certain limitations and disadvantages that should be considered. Here’s a detailed explanation of the limitations and disadvantages associated with drive shafts:

1. Length and Misalignment Constraints:

Drive shafts have a maximum practical length due to factors such as material strength, weight considerations, and the need to maintain rigidity and minimize vibrations. Longer drive shafts can be prone to increased bending and torsional deflection, leading to reduced efficiency and potential driveline vibrations. Additionally, drive shafts require proper alignment between the driving and driven components. Misalignment can cause increased wear, vibrations, and premature failure of the drive shaft or its associated components.

2. Limited Operating Angles:

Drive shafts, especially those using U-joints, have limitations on operating angles. U-joints are typically designed to operate within specific angular ranges, and operating beyond these limits can result in reduced efficiency, increased vibrations, and accelerated wear. In applications requiring large operating angles, constant velocity (CV) joints are often used to maintain a constant speed and accommodate greater angles. However, CV joints may introduce higher complexity and cost compared to U-joints.

3. Maintenance Requirements:

Drive shafts require regular maintenance to ensure optimal performance and reliability. This includes periodic inspection, lubrication of joints, and balancing if necessary. Failure to perform routine maintenance can lead to increased wear, vibrations, and potential driveline issues. Maintenance requirements should be considered in terms of time and resources when using drive shafts in various applications.

4. Noise and Vibration:

Drive shafts can generate noise and vibrations, especially at high speeds or when operating at certain resonant frequencies. Imbalances, misalignment, worn joints, or other factors can contribute to increased noise and vibrations. These vibrations may affect the comfort of vehicle occupants, contribute to component fatigue, and require additional measures such as dampers or vibration isolation systems to mitigate their effects.

5. Weight and Space Constraints:

Drive shafts add weight to the overall system, which can be a consideration in weight-sensitive applications, such as automotive or aerospace industries. Additionally, drive shafts require physical space for installation. In compact or tightly packaged equipment or vehicles, accommodating the necessary drive shaft length and clearances can be challenging, requiring careful design and integration considerations.

6. Cost Considerations:

Drive shafts, depending on their design, materials, and manufacturing processes, can involve significant costs. Customized or specialized drive shafts tailored to specific equipment requirements may incur higher expenses. Additionally, incorporating advanced joint configurations, such as CV joints, can add complexity and cost to the drive shaft system.

7. Inherent Power Loss:

Drive shafts transmit power from the driving source to the driven components, but they also introduce some inherent power loss due to friction, bending, and other factors. This power loss can reduce overall system efficiency, particularly in long drive shafts or applications with high torque requirements. It is important to consider power loss when determining the appropriate drive shaft design and specifications.

8. Limited Torque Capacity:

While drive shafts can handle a wide range of torque loads, there are limits to their torque capacity. Exceeding the maximum torque capacity of a drive shaft can lead to premature failure, resulting in downtime and potential damage to other driveline components. It is crucial to select a drive shaft with sufficient torque capacity for the intended application.

Despite these limitations and disadvantages, drive shafts remain a widely used and effective means of power transmission in various industries. Manufacturers continuously work to address these limitations through advancements in materials, design techniques, joint configurations, and balancing processes. By carefully considering the specific application requirements and potential drawbacks, engineers and designers can mitigate the limitations and maximize the benefits of drive shafts in their respective systems.

Can you provide real-world examples of vehicles and machinery that use drive shafts?

Drive shafts are widely used in various vehicles and machinery to transmit power from the engine or power source to the wheels or driven components. Here are some real-world examples of vehicles and machinery that utilize drive shafts:

1. Automobiles:

Drive shafts are commonly found in automobiles, especially those with rear-wheel drive or four-wheel drive systems. In these vehicles, the drive shaft transfers power from the transmission or transfer case to the rear differential or front differential, respectively. This allows the engine’s power to be distributed to the wheels, propelling the vehicle forward.

2. Trucks and Commercial Vehicles:

Drive shafts are essential components in trucks and commercial vehicles. They are used to transfer power from the transmission or transfer case to the rear axle or multiple axles in the case of heavy-duty trucks. Drive shafts in commercial vehicles are designed to handle higher torque loads and are often larger and more robust than those used in passenger cars.

3. Construction and Earthmoving Equipment:

Various types of construction and earthmoving equipment, such as excavators, loaders, bulldozers, and graders, rely on drive shafts for power transmission. These machines typically have complex drivetrain systems that use drive shafts to transfer power from the engine to the wheels or tracks, enabling them to perform heavy-duty tasks on construction sites or in mining operations.

4. Agricultural Machinery:

Agricultural machinery, including tractors, combines, and harvesters, utilize drive shafts to transmit power from the engine to the wheels or driven components. Drive shafts in agricultural machinery are often subjected to demanding conditions and may have additional features such as telescopic sections to accommodate variable distances between components.

5. Industrial Machinery:

Industrial machinery, such as manufacturing equipment, generators, pumps, and compressors, often incorporate drive shafts in their power transmission systems. These drive shafts transfer power from electric motors, engines, or other power sources to various driven components, enabling the machinery to perform specific tasks in industrial settings.

6. Marine Vessels:

In marine applications, drive shafts are commonly used to transmit power from the engine to the propeller in boats, ships, and other watercraft. Marine drive shafts are typically longer and designed to withstand the unique challenges posed by water environments, including corrosion resistance and appropriate sealing mechanisms.

7. Recreational Vehicles (RVs) and Motorhomes:

RVs and motorhomes often employ drive shafts as part of their drivetrain systems. These drive shafts transfer power from the transmission to the rear axle, allowing the vehicle to move and providing propulsion. Drive shafts in RVs may have additional features such as dampers or vibration-reducing components to enhance comfort during travel.

8. Off-Road and Racing Vehicles:

Off-road vehicles, such as SUVs, trucks, and all-terrain vehicles (ATVs), as well as racing vehicles, frequently utilize drive shafts. These drive shafts are designed to withstand the rigors of off-road conditions or high-performance racing, transmitting power efficiently to the wheels and ensuring optimal traction and performance.

9. Railway Rolling Stock:

In railway systems, drive shafts are employed in locomotives and some types of rolling stock. They transfer power from the locomotive’s engine to the wheels or propulsion system, enabling the train to move along the tracks. Railway drive shafts are typically much longer and may have additional features to accommodate the articulated or flexible nature of some train configurations.

10. Wind Turbines:

Large-scale wind turbines used for generating electricity incorporate drive shafts in their power transmission systems. The drive shafts transfer rotational energy from the turbine’s blades to the generator, where it is converted into electrical power. Drive shafts in wind turbines are designed to handle the significant torque and rotational forces generated by the wind.

These examples demonstrate the broad range of vehicles and machinery that rely on drive shafts for efficient power transmission and propulsion. Drive shafts are essential components in various industries, enabling the transfer of power from the source to the driven components, ultimately facilitating movement, operation, or the performance of specific tasks.

Can you explain the different types of drive shafts and their specific applications?

Drive shafts come in various types, each designed to suit specific applications and requirements. The choice of drive shaft depends on factors such as the type of vehicle or equipment, power transmission needs, space limitations, and operating conditions. Here’s an explanation of the different types of drive shafts and their specific applications:

1. Solid Shaft:

A solid shaft, also known as a one-piece or solid-steel drive shaft, is a single, uninterrupted shaft that runs from the engine or power source to the driven components. It is a simple and robust design used in many applications. Solid shafts are commonly found in rear-wheel-drive vehicles, where they transmit power from the transmission to the rear axle. They are also used in industrial machinery, such as pumps, generators, and conveyors, where a straight and rigid power transmission is required.

2. Tubular Shaft:

Tubular shafts, also called hollow shafts, are drive shafts with a cylindrical tube-like structure. They are constructed with a hollow core and are typically lighter than solid shafts. Tubular shafts offer benefits such as reduced weight, improved torsional stiffness, and better damping of vibrations. They find applications in various vehicles, including cars, trucks, and motorcycles, as well as in industrial equipment and machinery. Tubular drive shafts are commonly used in front-wheel-drive vehicles, where they connect the transmission to the front wheels.

3. Constant Velocity (CV) Shaft:

Constant Velocity (CV) shafts are specifically designed to handle angular movement and maintain a constant velocity between the engine/transmission and the driven components. They incorporate CV joints at both ends, which allow flexibility and compensation for changes in angle. CV shafts are commonly used in front-wheel-drive and all-wheel-drive vehicles, as well as in off-road vehicles and certain heavy machinery. The CV joints enable smooth power transmission even when the wheels are turned or the suspension moves, reducing vibrations and improving overall performance.

4. Slip Joint Shaft:

Slip joint shafts, also known as telescopic shafts, consist of two or more tubular sections that can slide in and out of each other. This design allows for length adjustment, accommodating changes in distance between the engine/transmission and the driven components. Slip joint shafts are commonly used in vehicles with long wheelbases or adjustable suspension systems, such as some trucks, buses, and recreational vehicles. By providing flexibility in length, slip joint shafts ensure a constant power transfer, even when the vehicle chassis experiences movement or changes in suspension geometry.

5. Double Cardan Shaft:

A double Cardan shaft, also referred to as a double universal joint shaft, is a type of drive shaft that incorporates two universal joints. This configuration helps to reduce vibrations and minimize the operating angles of the joints, resulting in smoother power transmission. Double Cardan shafts are commonly used in heavy-duty applications, such as trucks, off-road vehicles, and agricultural machinery. They are particularly suitable for applications with high torque requirements and large operating angles, providing enhanced durability and performance.

6. Composite Shaft:

Composite shafts are made from composite materials such as carbon fiber or fiberglass, offering advantages such as reduced weight, improved strength, and resistance to corrosion. Composite drive shafts are increasingly being used in high-performance vehicles, sports cars, and racing applications, where weight reduction and enhanced power-to-weight ratio are critical. The composite construction allows for precise tuning of stiffness and damping characteristics, resulting in improved vehicle dynamics and drivetrain efficiency.

7. PTO Shaft:

Power Take-Off (PTO) shafts are specialized drive shafts used in agricultural machinery and certain industrial equipment. They are designed to transfer power from the engine or power source to various attachments, such as mowers, balers, or pumps. PTO shafts typically have a splined connection at one end to connect to the power source and a universal joint at the other end to accommodate angular movement. They are characterized by their ability to transmit high torque levels and their compatibility with a range of driven implements.

8. Marine Shaft:

Marine shafts, also known as propeller shafts or tail shafts, are specifically designed for marine vessels. They transmit power from the engine to the propeller, enabling propulsion. Marine shafts are usually long and operate in a harsh environment, exposed to water, corrosion, and high torque loads. They are typically made of stainless steel or other corrosion-resistant materials and are designed to withstand the challenging conditions encountered in marine applications.

It’simportant to note that the specific applications of drive shafts may vary depending on the vehicle or equipment manufacturer, as well as the specific design and engineering requirements. The examples provided above highlight common applications for each type of drive shaft, but there may be additional variations and specialized designs based on specific industry needs and technological advancements.

editor by CX 2024-04-08

in Samsun Turkey sales price shop near me near me shop factory supplier Ce Certificate High Quality Dq1104 110HP 4X4 4WD Big Wheel Type Agrilcultural Farm Tractor manufacturer best Cost Custom Cheap wholesaler

Our experts and engineers have 23 several years of Encounter in the Bearing Industry. EPG is a skilled company and exporter that is concerned with the layout, development and generation. If you are intrigued in any of our products or would like to go over a potential purchase, make sure you come to feel cost-free to make contact with us. CE certification EPT EPTT Dq1104 110HP 4X4 4 wheel drive Massive Wheel Sort Agrilcultural Farm Tractor

Tractor Major Attributes and Advantages:

1.Geared up famous manufacturer motor exhibiting EPTd potential,reduced gas consumption,large financial effectiveness.

2. Streamlined appearance layout, beautiful and generous.

3.EPTT Case undertake meshed shift and add the EPTT interlock device tends to make the procedure a lot more smoothly,dependable and simpler.

4. EPTT action clutch with disc EPT, carry out steadily and easy to function.

5. Completely EPT steering program tremendously decreased EPTr’s operate strength.

6. Wet disc brake unit, reliable brake performance.

7. Separate EPT of EPT oil, dependable to operate.

eight. The lifter with drive and position adjustment, with trustworthy carry.

9. Tractor PTO:

PTO in EPTT pace : 540/760r/min Optional, For large doing work effectiveness.

PTO shaft of six or eight spline Optional, adaptable for agricultural equipment of all in excess of the world.

ten. Big Chassis and EPT-obligation Rear axle for EPTTble EPT EPTT.

11. Entire collection light, ROPS,Sunshade/Cover, Admirer/Heater/Air-conditioned cabin are all accessible, for more relaxed driving atmosphere.

Tractor Primary specificaiton and EPTnical parameters:

| Tractor Model | DQ1104 |

| Push kind | 4×4 |

| Engine | |

| Engine kind | YTO or EPTchai brand name, 4 cylinEPTTdiesel motor |

| Ability of gasoline tank(L) | 150 |

| Rated speed (r/min) | 2300 |

| Engine EPTT at rated pace(kw/hp) | 81kw/110HP |

| EPTT | |

| EPTT | Dry,Twin-stage type |

| PTO Velocity (rpm) | 540/one thousand or 760/1000 |

| EPT shift | 8F 4R/16F 8R(optional)/8F 8R(optional) |

| EPT program | |

| EPT output valve | two-Team (optional) |

| 3 position linkage | |

| Group of three-stage link | Group II |

| EPT power @ level of 610mm) KN | gt18 |

| EPTnical parameter | |

| Dimension (LxWxH) (mm) | 4593x2050x2810 |

| Wheel base(mm) | 2195 |

| Keep track of foundation(mm) entrance wheel | 1610 |

| Observe foundation(mm) rear wheel | 1620-2571 (usual 1620) |

| The smallest clearance(mm) | 379 |

| Front tyre | eleven.2-24 |

| Rear tyre | sixteen.nine-34(widespread)/18.four-thirty(optional) |

| Optional Configurations | |

| Common cabin with Supporter Heater cabin AC cabin ROPS Cover (Sunshade) 8F 8R shuttle EPTshift, 16F 4R creeper EPTshift, 2-Group EPT output valve Front ballast, Rear ballast Paddy tire, seven.5-sixteen front tire, 18.4-30 big rear tire, six cylinEPTTdiesel motor, EPT-duty rear, Air brake, EPTg attract bar | |

| Loading EPTtity/40HC | 3 Sets in Nude EPTT for CBU shipping |

DQ1104 110HP 4wd Tractror displaying :

Advance Manufacutring Line:

Strictly Inspecting and Complete Tests for making certain large good quality solution:

Tractor EPTT and Loading container for Providing merchandise :

A variety of Transportation modes and Delivery phrase to meet up with various buyers demand :

Please get in touch with us if you have any demand for our item :

John li

EPT Director

WeiEPTT Yourchance EPTTry EPTT, Ltd.

Include: No.5097 EPT EPT Street,WeiEPTT,EPTT.

TEL: 15169426352

EPTT cost will be quoted for you as shortly as EPT your Necessity !

in Moradabad India sales price shop near me near me shop factory supplier High Quality Enfly Brand 80HP 85HP 90HP 95HP 100HP 110HP 4X4 4WD Big Agriculture Wheel Farming Tractor with Td Bype Big Chassis for Sale manufacturer best Cost Custom Cheap wholesaler

There is a specialized center of province stage, EPG academician functioning station, experiment station for EPG submit physicians, and nationwide 863 system set up in EPG team. With these platforms and sturdy technical capability, the more than 400 specialists have designed all variety of particular substantial precise and high toughness goods, executed mildew plans for essential components in the auto and countrywide industry revitalizing plan, ensuing much more than 5000 created over, between which 33 items are autonomous patent technological innovation with four patent accepted . Fantastic interest has been paid out on environmental safety and power saving. We offer OEM service. EPT high quality Enfly brand name 80HP 85HP 90HP 95HP 100HP 110HP 4×4 4wd Huge EPTT wheel Farming Tractor with TD bype huge Chassis for sale

Tractor Major Functions and Benefits:

one.Geared up renowned brand motor showing EPTd capability,reduced fuel intake,higher economic efficiency.

two. Streamlined look style, lovely and generous.

three.EPTT Scenario undertake meshed shift and incorporate the EPTT interlock system can make the operation much more smoothly,trustworthy and easier.

four. EPTT motion clutch with disc EPT, complete steadily and straightforward to function.

5. Fully EPT steering system tremendously diminished EPTr’s perform strength.

6. Moist disc brake system, reputable brake performance.

seven. Separate EPT of EPT oil, trustworthy to function.

eight. The lifter with pressure and situation adjustment, with reputable elevate.

9. Tractor PTO:

PTO in EPTT velocity : 540/760r/min Optional, For higher functioning effectiveness.

PTO shaft of six or eight spline Optional, adaptable for agricultural products of all in excess of the globe.

ten. Large Chassis and EPT-obligation Rear axle for EPTTble EPT EPTT.

11. Full series mild, ROPS,Sunshade/Cover, Supporter/Heater/Air-conditioned cabin are all offered, for far more cozy driving surroundings.

Tractor Principal specificaiton and EPTnical parameters:

| Tractor Model | DQ1004 |

| Travel variety | 4×4, Four wheel drive |

| Engine | |

| Motor kind | YTO or EPTchai brand, 4 or 6 cylinEPTTdiesel engine |

| Capacity of fuel tank(L) | one hundred fifty |

| Rated speed (r/min) | 2300 |

| Motor EPTT at rated speed(kw/hp) | 73.5kw/100HP |

| EPTT | |

| EPTT | Dry,Twin-phase variety |

| PTO Pace (rpm) | 540/1000 or 760/one thousand |

| EPT shift | 8F 4R/16F 8R(optional)/8F 8R(optional) |

| EPT program | |

| EPT output valve | two-Group (optional) |

| Three level linkage | |

| Category of 3-point website link | Category II |

| EPT force @ point of 610mm) KN | gt16 |

| EPTnical parameter | |

| Dimension (LxWxH) (mm) | 4593x2050x2810 |

| Wheel base(mm) | 2195 |

| Track base(mm) front wheel | 1610 |

| Monitor base(mm) rear wheel | 1620-2571 (normal 1620) |

| The smallest clearance(mm) | 379 |

| Entrance tyre | 11.2-24 |

| Rear tyre | sixteen.nine-34(common)/18.four-30(optional) |

| Optional Configurations | |

| Common cabin with Supporter Heater cabin AC cabin ROPS Cover (Sunshade) 8F 8R shuttle EPTshift, 16F 4R creeper EPTshift, 2-Group EPT output valve Front ballast, Rear ballast Paddy tire, 7.5-16 entrance tire, eighteen.4-thirty massive rear tire, six cylinEPTTdiesel motor, EPT-responsibility rear, Air brake, EPTg draw bar | |

| Loading EPTtity/40HC | three Sets in Nude EPTT for CBU transport |

Tractror particulars displaying:

Tractor have various configurations for you select:

Progress Manufacutring Line :

Strictly Inspecting and Total Testing for making sure substantial high quality solution:

Tractor EPTT, Loading container and Offering items to Customers :

EPTT cost will be quoted for you as soon as EPT your Necessity !

Best China manufacturer & factory Brand in Osaka Japan Tractor Parts Driveline Triangular Pto Spline Shaft Coupling With high quality best price

If you need any information or samples, please contact us and you will have our soon reply.

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant, OEM

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

- Showroom Location:

-

none

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

Our products are selling well in Chinese markets and some products sold in international markets are well received by Chinese and foreign clients at home and abroad.

- Material:

-

Metal

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Design:

-

Customized

- Certificate:

-

CE Certificate

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Packing details:Iron pallet&wooden carton&standard export packaging

- Port

- ningbo or shanghai

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical cCompared to other types of gears, worm gears are unique and have very distinctive characteristics and uses. This post will focus on the advantages of worm gears. For a list of common worm gear applications, please see worm gear capabilities.omponent, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Customized |

| Certificate | CE Certificate |

Product Display

Product Display

PTO Drive Line Gen …

Tie RodSlip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST MODELS three different types of PTO in operation: a non shear, shear pin and slip clutch — the last being the most expensive. Implement end of non shear (r) and shear type (l) Non shear: this is a solid yoke to yoke set up and used with the expectation that certain equipment will not encounter any sudden stops. I figure that the finishing mower does not need a shear set up as the blades will slip to a degree being belt driven and my other mower, the flail mower, is extremely forgiving in its design. Cylinder H …

Agricultural Gearb …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……

Best China manufacturer & factory china manufacturer and factory of tractor With high quality best price

Due to our sincerity in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements,a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Model Number:

-

JS-650 / 654

SFI M100 PTO AdapterAs a precautionary measure, it is a good idea to purchase a PTO adapter to ensure compatibility with your particular tractor model.

- After-sales Service Provided:

-

No overseas service provided

- Power:

-

75 HP

Supply Ability

- Supply Ability:

- 100 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- In Container with Protective Frame

- Port

- nb

Online Customization

Product Description

We are We – EPG – One of the biggest agri-parts factory in China – Machinery, China. We sell good farm tractors with fair price.

Model JS-650 / 654

JS-650 / 654 Series have both 2WD and 4WD type tractor for dry and paddy field and for transportation. It can be used for various farm working with many implements, such as plough, harrow, harvest machine, flail mower , trailer etc.

CE and ISO certificate

Four-wheel-drive, a well sealed drive axle

Non-maintenance of battery

Equipped with famous engine, lower oil consumption, high torque reservoir, excellent starting

Excellent working with draft control lever and position control lever, hydraulic steering system.

Streamline shape, compound panel

Optional ROPS, canopy, enclosed cabin, multi-way hydraulic valThe company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial rob• output < 0,55 (see table of technical features).ot etc. ve

We also supply all kinds of plough, harrow, harvest machine, flail mower , trailer etc.

Best China manufacturer & factory Competitive Price Top Quality Pto For Tractor Prices With high quality best price

More importantly, we make special parts according to supplied drawings/samples and warmly welcome OEM inquiries.

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

Cat 3 Point Hitch How do I operate the PTO on my tractor? Prior to running the PTO, you will need your tractor to reach the starting RPM (revolutions per minute). Once the starting RPM has been reached you can begin operating the PTO.

- Local Service Location:

-

none, Italy

- Showroom Location:

-

ITALY

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Design:

-

Customized

- Certificate:

-

CE Certificate

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Packing details:Iron pallet&wooden carton&standard export packaging

- Port

- ningbo or shanghai

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video t Industrial Gearbox-EPG Series GEPG Drive Industrial Reducer Series G The Series G helical parallel shaft and bevel helical right angle drive industrial gearbox were introduced to meet the requirements of today’s demanding applications in the medium and heavy-duty sector of the power transmission market. Innovative modular design technology has minimized manufactured part count to maximize availability of product. Industrial Gearbox – David Brown Series H The Series H industrial gearbox is available in iEPG Drive Industrial Gearbox David Brownn-line and right angle versions in single, double, triple and quadruple reduction gear stages. The modular design and construction of the Series H offers many engineering and performance benefits including a high degree of interchangeability of parts and sub assemblies. This in turn provides considerable economies of production while maintaining the highest standard of component integrity.echnical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts The company was certified by ISO9001:2008 Quality Management System. |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Color | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Customized |

| Certificate | CE Certificate |

Product Display

Product Display

PTO Drive Line Gen …

Industrial-Duty Ro …

Tie Rod Cylinder H …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……

High China jeep tj driveshaft Quality Agricultural Equipment Dq1104 110HP 4WD Big Wheel Farming Tractor From Tractor Factory Manufacturer with ce certificate top quality low price

We – EPG Team the greatest agricultural gearbox and pto factory in China with five different branches. For a lot more particulars: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

We are ISO 9001:2008 certified business. We are a foremost producer, provider, wholesaler, importer and exporter of extensive variety of Good quality assured Automobile and Pump Castings Parts. Our supplied items are C EPT Iron Casting, Iron Castings and Valve Casting. Some of the exclusive characteristics of our products are toughness, dimensional precision, reduced maintenance and corrosion resistance. Supported by an ultra-modern day infrastructure established-up equipped with modern machines and gear, we have been creating the goods as for every the specs thorough by the consumers. We are Export in Africa, England, Malaysia, ZheJiang , Usa & UAE. Large top quality Agricultural Tools DQ1104 110HP 4wd Big wheel Farming tractor from Tractor manufacturing unit manufacturer

Tractor Primary Features and Advantages:

one.Equipped well-known brand name engine demonstrating advanced ability,reduced gasoline intake,higher financial effectiveness.

two. Streamlined visual appeal design, lovely and generous.

3.Transmission Situation undertake meshed change and add the gearbox interlock unit helps make the operation a lot more efficiently,dependable and less difficult.

four. Double motion clutch with disc spring, complete steadily and simple to work.

5. Fully hydraulic steering method tremendously diminished driver’s perform strength.

six. Wet disc brake device, trustworthy brake functionality.

seven. Individual injection of hydraulic oil, trustworthy to function.

8. The lifter with drive and place adjustment, with trustworthy elevate.

9. Tractor PTO:

PTO in Double pace : 540/ 571 r/min Optional, For high functioning effectiveness.

PTO shaft of 6 or 8 spline Optional, adaptable for agricultural products of all more than the planet.

ten. Massive Chassis and Hefty-duty Rear axle for Durable Robust device.

eleven. Total sequence light-weight, ROPS,Sunshade/Canopy, Fan/Heater/Air-conditioned cabin are all accessible, for much more cozy driving surroundings.

Tractor Major specificaiton and Specialized parameters:

| Tractor Model | DQ1104 |

| Drive kind | 4×4 |

| Engine | |

| Motor variety | EPT or Yuchai manufacturer, 4 cylinder EPT engine |

| Ability of gas tank(L) | a hundred and fifty |

| Rated speed (r/min) | 2300 |

| Motor electricity at rated speed(kw/hp) | 81kw/110HP |

| Transmission | |

| Clutch | Dry,Twin-stage variety |

| PTO Pace (rpm) | 540/1000 or 571 /one thousand |

| Gear shift | 8F+4R/16F+8R(optional)/8F+8R(optional) |

| Hydraulic system | |

| Hydraulic output valve | 2-Group (optional) |

| Three point linkage | |

| Group of 3-position url | Classification II |

| Lifting force @ point of 610mm) KN | >18 |

| Complex parameter | |

| Dimension (LxWxH) (mm) | 571 3x2050x2810 |

| Wheel base(mm) | 2195 |

| Track base(mm) front wheel | 1610 |

| Observe foundation(mm) rear wheel | 1620-2571 (normal 1620) |

| The smallest clearance(mm) | 571 |

| Entrance tyre | eleven.2-24 |

| Rear tyre | 16.9-34(common)/eighteen.4-thirty(optional) |

| Optional Configurations | |

| Widespread cabin with Admirer Heater cabin AC cabin ROPS Canopy (Sunshade) 8F+8R shuttle gearshift, 16F+4R creeper gearshift, two-Group Hydraulic output valve Front ballast, Rear ballast Paddy tire, 7.5-sixteen entrance tire, 18.four-30 big rear tire, 6 cylinder EPT engine, Weighty-obligation rear, Air brake, Swing attract bar | |

| Loading Amount/40HC | three Sets in Nude packing for CBU delivery |

DQ1104 110HP 4 wheel drive Tractror displaying :

DQ1104 110HP 4 wheel drive Tractor have distinct optional configurations for choose :

EPT Manufacutring Line:

Strictly Inspecting and Entire Screening for guaranteeing large good quality item:

Tractor Packing and Loading container for Providing items :

Various Transport modes and Delivery time period to fulfill different clients demand :

You should get in touch with us if you have any need for our product :

John li

Income Director

HangZhou EPT Machinery Co., Ltd.

Add: No.5097 Shengli E EPT Street,HangZhou,China.

TEL: 0086 one 571 9426 571

Ideal cost will be quoted for you as shortly as acquire your Necessity !

factory factory Wholesale Suppliers Online manufacturer for High quality tractor miniature bevel gear joyner iseki

we offer chromed bar and tubes for hydualic and pheumatic cylinders, pto shaft, agricultural gearboxes and so forth.

Overview

Swift Specifics

- Applicable Industries:

-

Manufacturing Plant

- Item Search phrases:

-

tractor miniature bevel equipment,tractor joyner equipment,tractor iseki gear

Offer Potential

- Provide Capability:

- 5000 Piece/Pieces for each Thirty day period

Packaging & Shipping

- Packaging Specifics

- Neutral paper packaging, wood bins for outer box or in accordance to customer’s demand.

- Port

- Shanghai Port / Ningbo Port

Online Customization

We Ever-Power Group with four branches over 1200 employees is one particular of the largest transmission components and machining objects makers in China

Product Description

Merchandise Description:

We specialized in manufacturing car gears , bike gears, gearbox, particular vehicle (energy takeoff, snowmobiles, engineering vehicles) gears, generator add-ons, stainless metal ice crusher etc.

|

Content |

1020,1045,20CrMnTi, and so on. |

|

Machining Method |

Equipment Hobbing , Equipment Shaping, Equipment Shaving, Equipment Grinding |

|

Modules |

one., 1.25, 1.5, 1.seventy five, two., 2.25, two.five….eight. and many others. |

|

Warmth Remedy |

Carburizing & Quenching, Carbonitriding |

|

Common |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

High made in china quality Tractor PTO Cardan Shafts for agricultural implement with CE certificate

our products are promoting well in the American, European, South American and Asian marketplaces. a specialised supplier of a total variety of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Rapid Information

- Guarantee:

-

1.5 a long time

- Relevant Industries:

-

Producing Plant

- Right after Guarantee Provider:

-

On the internet help

- Regional Provider Location:

-

None, Italy

- Showroom Spot:

-

Italy

- Kind:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand name Title:

-

OEM

- certificate:

-

CE

- Materials:

-

Steel

- Construction:

-

W or S

- Tube:

-

Triangular, Lemon, Star and so on

- Approach:

-

Solid

- Layout:

-

Customized

- Certification:

-

CE Certification

- The size of cross package:

-

22*5423.8*sixty one.327*7027*seventy four.630.2*8030.two*9230.2*106.535*106.5

- The dimension of spline:

-

one three/8” Z6 one three/8” Z21 one three/4” Z6 1 three/4” Z6 1 1/8” Z6 8*32*38*six

Source Potential

- Source Capability:

- 20000 Piece/Parts for every Thirty day period

Packaging & Supply

- Packaging Information

- Packing specifics:Iron pallet&wooden carton&standard export packaging

- Port

- NINGBO OR SHANGHAI

On the web Customization

Solution Details

Solution Details

PTO Shaft

The energy just take-off (PTO) is a sophisticated system, making it possible for implements to draw energy from the motor and transmit it to yet another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The electricity consider-off shaft (PTO shaft) is a essential component, developed and produced for continuous large-duty use. A good PTO shaft need to be powerful adequate to bear the torsion and shear anxiety and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Team, manufactures cold extruded PTO shafts for all sorts of agriculture cars. Our PTO shafts provide fantastic dependability and toughness during everyday use.

EP Group has been internationally identified as a trustworthy world-wide supplier. Our point out-of-the-art production method and knowledgeable engineers ensure the leading-quality of all Farinia factors.

| After Guarantee Support | Video technological support |

| Applicable Industries | Production Plant |

| Nearby Service Location | Italy |

| Showroom Area | Italy |

| Warranty | one.5 years |

| Type | Shafts |

| Location of Origin | China |

| China | Zhejiang |

| Brand name Identify | EPG |

| certification | CE |

| Content | Steel |

| Construction | W or S |

| Tube | Triangular, Lemon, Star and so forth |

| Process | Cast |

| Design | Personalized |

| Certification | CE Certificate |

| The measurement of cross package | 22*5423.eight*61.327*7027*74.630.two*8030.two*9230.2*106.535*106.5 |

| The dimensions of spline | one 3/8” Z6 one 3/8” Z21 one three/4” Z6 one 3/4” Z6 one 1/8” Z6 eight*32*38*six |

| Deal | Iron pallet&wooden carton&standard export packaging |

Merchandise Screen

Product Exhibit

eighteen” Large Duty Ear …

Tie Rod Cylinder H …

PTO Drive Line Gen …

CompanyInfo

Company Profile

Ever-Power Team

EPG have high-tech machinery and examination gear. We can make entire world class substantial precision items.

Certifications

Certifications

Cargo & Payment

Our Positive aspects

A: Your inquiry connected to our merchandise or costs will be replied in 24 several hours.

B: Safety of your revenue area, concepts of design and style and all your private info.

C: Ideal good quality and competitive cost.

……

faq

FAQ

1) How can I location get?

A: You can contact us by e mail about your buy specifics, or area order on line.

two) How can I pay out you?

A: Right after you validate our PI, we will request you to pay. T/T (HSBC financial institution) and Paypal, Western Union are the most normal approaches we are making use of.

……