Product Description

Spline Round Key Way Pin Threaded CZPT Hollow Through Hole Flat D Shape Knurling Spur Helical Worm Transmission Drive Auto Parts Gear Pinion Gearbox Axis Shaft

Features

1. High precision gear shaft for smooth, quiet operation.

2. Flexible for custom-made requests.

3. Stable transmission, low impact, vibration, and noise.

4. Heavy Load capability, more compact, but less complex.

Product Description

| Products | Spur Gear, Helical Gear, Herringbone Gear, Spiral Bevel Gear, Straight Bevel Gear, Worm Gear, Shaft, Pinion |

| Module | M0.3-M10 |

| Precision grade | DIN6, DIN7, DIN8, DIN10 |

| Pressure angle | 14.5 degree, 15 degree, 20 degree |

| Material | Medium Carbon Steel: 35#, 45# Carburizing Steel: 20CrMnTi, 20CrMnMo, 20CrMo Alloy Steel: 40Cr, 35CrMo, 42CrMo, 40CrNiMo Cast Iron: HT250, QT400 Copper, Stainless Steel, Brass, Nylon, POM, and so on |

| Heat treatment | Hardening & Tempering, Surface Quenching, Integral Quenching, Carburizing Quenching, Tempering, Normalizing, Nitriding |

| Surface treatment | Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

| Application | Gearbox and reducer; Precision cutting machines, Lathes machines; Milling machines; Grinder machine; Automated mechanical systems; Automated warehousing systems. Gear hobbing machines, gear shapers, gear shaving machines, gear milling, gear grinding machines and many kinds of gear-related machines. |

| Machining process | Forging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment… |

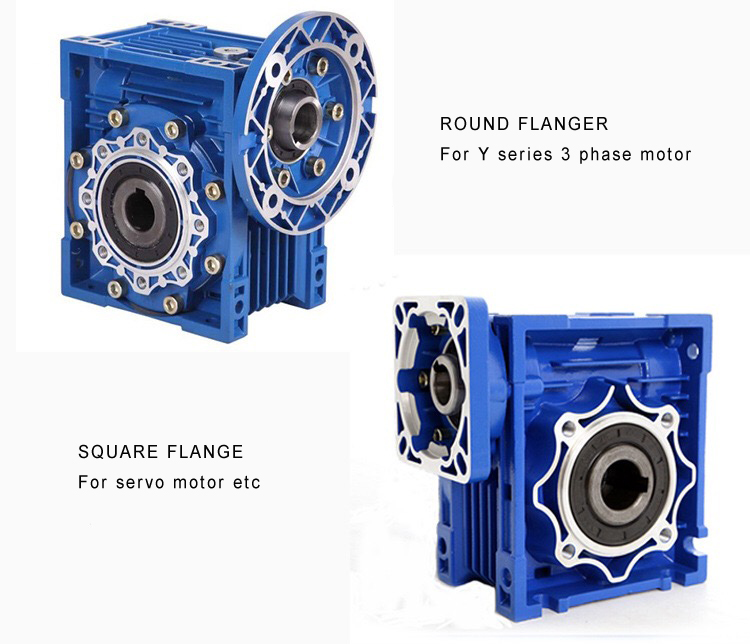

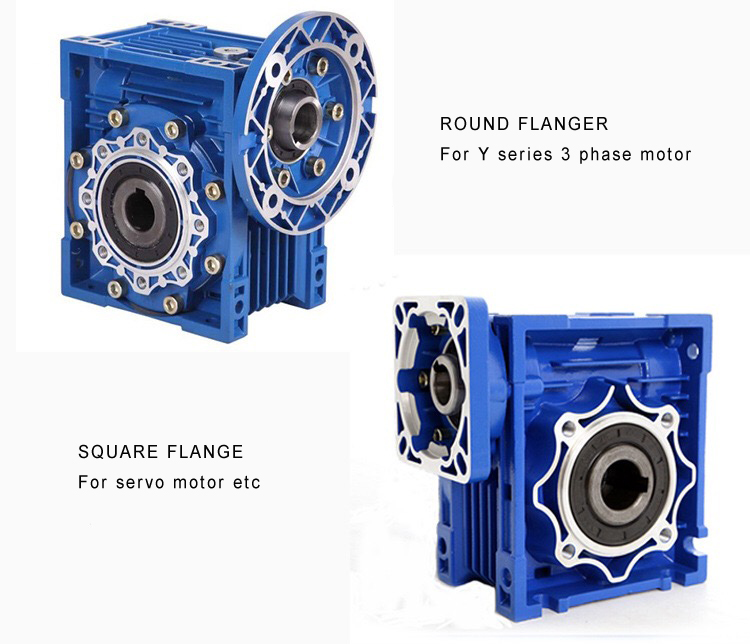

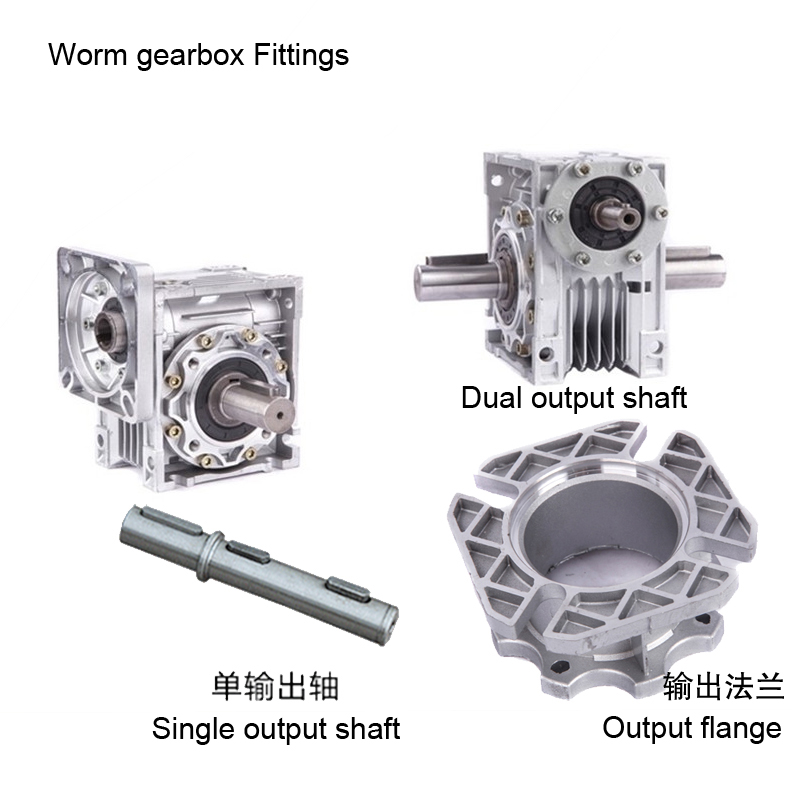

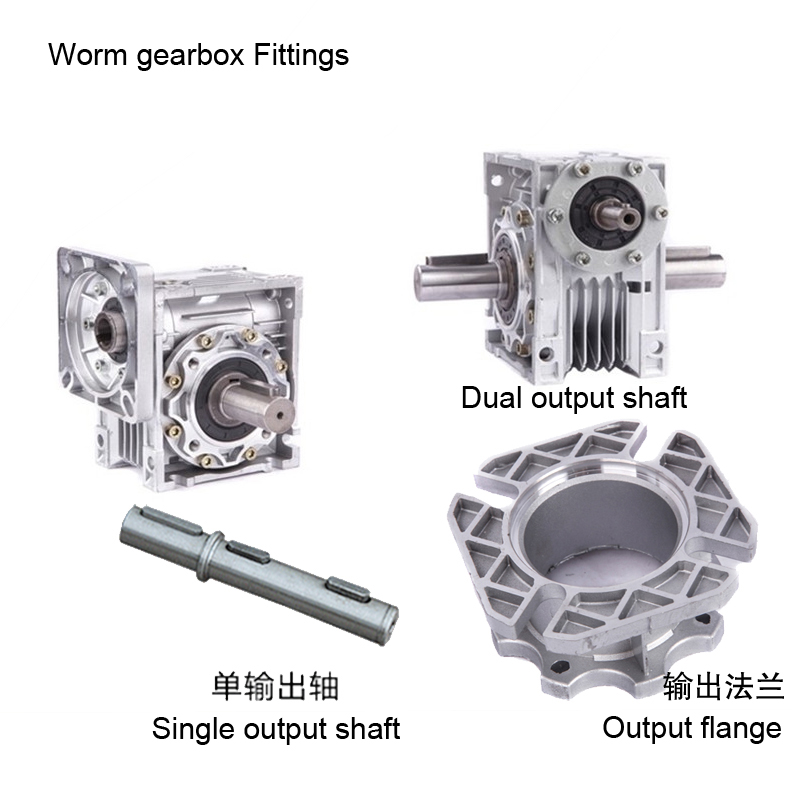

Detailed Photos

Our Advantages

Related Product

Company Profile

FAQ

Q: How to ship the worm gear to us?

A: It is available by air, sea, or train.

Q: How to pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Gearbox |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample Worm gear with shaft

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

How do drive shafts handle variations in load and vibration during operation?

Drive shafts are designed to handle variations in load and vibration during operation by employing various mechanisms and features. These mechanisms help ensure smooth power transmission, minimize vibrations, and maintain the structural integrity of the drive shaft. Here’s a detailed explanation of how drive shafts handle load and vibration variations:

1. Material Selection and Design:

Drive shafts are typically made from materials with high strength and stiffness, such as steel alloys or composite materials. The material selection and design take into account the anticipated loads and operating conditions of the application. By using appropriate materials and optimizing the design, drive shafts can withstand the expected variations in load without experiencing excessive deflection or deformation.

2. Torque Capacity:

Drive shafts are designed with a specific torque capacity that corresponds to the expected loads. The torque capacity takes into account factors such as the power output of the driving source and the torque requirements of the driven components. By selecting a drive shaft with sufficient torque capacity, variations in load can be accommodated without exceeding the drive shaft’s limits and risking failure or damage.

3. Dynamic Balancing:

During the manufacturing process, drive shafts can undergo dynamic balancing. Imbalances in the drive shaft can result in vibrations during operation. Through the balancing process, weights are strategically added or removed to ensure that the drive shaft spins evenly and minimizes vibrations. Dynamic balancing helps to mitigate the effects of load variations and reduces the potential for excessive vibrations in the drive shaft.

4. Dampers and Vibration Control:

Drive shafts can incorporate dampers or vibration control mechanisms to further minimize vibrations. These devices are typically designed to absorb or dissipate vibrations that may arise from load variations or other factors. Dampers can be in the form of torsional dampers, rubber isolators, or other vibration-absorbing elements strategically placed along the drive shaft. By managing and attenuating vibrations, drive shafts ensure smooth operation and enhance overall system performance.

5. CV Joints:

Constant Velocity (CV) joints are often used in drive shafts to accommodate variations in operating angles and to maintain a constant speed. CV joints allow the drive shaft to transmit power even when the driving and driven components are at different angles. By accommodating variations in operating angles, CV joints help minimize the impact of load variations and reduce potential vibrations that may arise from changes in the driveline geometry.

6. Lubrication and Maintenance:

Proper lubrication and regular maintenance are essential for drive shafts to handle load and vibration variations effectively. Lubrication helps reduce friction between moving parts, minimizing wear and heat generation. Regular maintenance, including inspection and lubrication of joints, ensures that the drive shaft remains in optimal condition, reducing the risk of failure or performance degradation due to load variations.

7. Structural Rigidity:

Drive shafts are designed to have sufficient structural rigidity to resist bending and torsional forces. This rigidity helps maintain the integrity of the drive shaft when subjected to load variations. By minimizing deflection and maintaining structural integrity, the drive shaft can effectively transmit power and handle variations in load without compromising performance or introducing excessive vibrations.

8. Control Systems and Feedback:

In some applications, drive shafts may be equipped with control systems that actively monitor and adjust parameters such as torque, speed, and vibration. These control systems use sensors and feedback mechanisms to detect variations in load or vibrations and make real-time adjustments to optimize performance. By actively managing load variations and vibrations, drive shafts can adapt to changing operating conditions and maintain smooth operation.

In summary, drive shafts handle variations in load and vibration during operation through careful material selection and design, torque capacity considerations, dynamic balancing, integration of dampers and vibration control mechanisms, utilization of CV joints, proper lubrication and maintenance, structural rigidity, and, in some cases, control systems and feedback mechanisms. By incorporating these features and mechanisms, drive shafts ensure reliable and efficient power transmission while minimizing the impact of load variations and vibrations on overall system performance.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2023-12-13

China OEM NRV Worm speed gear box reducer with Hot selling

Main Products Type Worm Gear Speed Reducer/ gearbox Model WMRV 25/30/40/50/63/75/90/110/130/150/185 Ratio 7.5,10,15,20,25,30,40,50,60,80,100. Color Blue(RAL5571)/Silver grey (K9149) Or On Customer Request Material Aluminum alloy Worm wheel: Aluminum Bronze or Zinc Bronze Worm shaft: 20CrMn Ti Output Shaft: steel-45# Packing Carton, Best selling 5 speed F10A gearbox suitable for engine Honey Comb Carton, Wooden Case with wooden pallet Warranty 1 Year Input Power 0.09kw,0.18kw,1.1KW,1.5KW,2.2KW,3KW,4KW,5.5KW,7.5KW,11Kw and so on. Usages Industrial Machine: Food Stuff, Shot Blasting Counter Shaft Assy Rotary Kin Wheel Gear Wheel Cam Shaft Gear Ceramics, CHEMICAL, Packing, Dyeing,Wood working, Glass. IEC Flange IEC standard flange or on customer request Lubricant Synthetic oil or worm gear oil >Click Here To Contact< Product Advantages Enterprise Strength Certificate Global Exhibition Customer Comments FAQ 1. How to choose a gearbox which meets our requirement?You can refer to our catalogue to choose the gearbox or we can help to choose when you providethe technical information of required output torque, output speed and motor parameter etc. 2. What information shall we give before placing a purchase order?a) Type of the gearbox, ratio, input and output type, Transmission speed Reducer Cast Iron Housing Geared Motor Reduction Helical Cycloidal Cyclo Planetary Worm Gear Box Gearbox input flange, mounting position, and motor informationetc.b) Housing color.c) Purchase quantity.d) Other special requirements. 3. What industries are your gearboxes being used?Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, High Quality Standard Size Rear Car Auto Parts Outer Drive Shaft Wheel Side CV Joint A6 38-59.5-27 SingSpareParts From Singapore logistics and etc. 4. Doyou sell motors?We have stable motor suppliers who have been coperating with us for a long-time. They can provide motorswith high quality. >Return Home<

What Are Worm Gears and Worm Shafts?

If you’re looking for a fishing reel with a worm gear system, you’ve probably come across the term ‘worm gear’. But what are worm gears and worm shafts? And what are the advantages and disadvantages of worm gears? Let’s take a closer look! Read on to learn more about worm gears and shafts! Then you’ll be well on your way to purchasing a reel with a worm gear system.

worm gear reducers

Worm shaft reducers have a number of advantages over conventional gear reduction mechanisms. First, they’re highly efficient. While single stage worm reducers have a maximum reduction ratio of about five to sixty, hypoid gears can typically go up to a maximum of one hundred and twenty times. A worm shaft reducer is only as efficient as the gearing it utilizes. This article will discuss some of the advantages of using a hypoid gear set, and how it can benefit your business.

To assemble a worm shaft reducer, first remove the flange from the motor. Then, remove the output bearing carrier and output gear assembly. Lastly, install the intermediate worm assembly through the bore opposite to the attachment housing. Once installed, you should carefully remove the bearing carrier and the gear assembly from the motor. Don’t forget to remove the oil seal from the housing and motor flange. During this process, you must use a small hammer to tap around the face of the plug near the outside diameter of the housing.

Worm gears are often used in reversing prevention systems. The backlash of a worm gear can increase with wear. However, a duplex worm gear was designed to address this problem. This type of gear requires a smaller backlash but is still highly precise. It uses different leads for the opposing tooth face, which continuously alters its tooth thickness. Worm gears can also be adjusted axially.

worm gears

There are a couple of different types of lubricants that are used in worm gears. The first, polyalkylene glycols, are used in cases where high temperature is not a concern. This type of lubricant does not contain any waxes, which makes it an excellent choice in low-temperature applications. However, these lubricants are not compatible with mineral oils or some types of paints and seals. Worm gears typically feature a steel worm and a brass wheel. The brass wheel is much easier to remodel than steel and is generally modeled as a sacrificial component.

The worm gear is most effective when it is used in small and compact applications. Worm gears can greatly increase torque or reduce speed, and they are often used where space is an issue. Worm gears are among the smoothest and quietest gear systems on the market, and their meshing effectiveness is excellent. However, the worm gear requires high-quality manufacturing to perform at its highest levels. If you’re considering a worm gear for a project, it’s important to make sure that you find a manufacturer with a long and high quality reputation.

The pitch diameters of both worm and pinion gears must match. The two worm cylinders in a worm wheel have the same pitch diameter. The worm wheel shaft has two pitch cylinders and two threads. They are similar in pitch diameter, but have different advancing angles. A self-locking worm gear, also known as a wormwheel, is usually self-locking. Moreover, self-locking worm gears are easy to install.

worm shafts

The deflection of worm shafts varies with toothing parameters. In addition to toothing length, worm gear size and pressure angle, worm gear size and number of helical threads are all influencing factors. These variations are modeled in the standard ISO/TS 14521 reference gear. This table shows the variations in each parameter. The ID indicates the worm shaft’s center distance. In addition, a new calculation method is presented for determining the equivalent bending diameter of the worm.

The deflection of worm shafts is investigated using a four-stage process. First, the finite element method is used to compute the deflection of a worm shaft. Then, the worm shaft is experimentally tested, comparing the results with the corresponding simulations. The final stage of the simulation is to consider the toothing geometry of 15 different worm gear toothings. The results of this step confirm the modeled results.

The lead on the right and left tooth surfaces of worms is the same. However, the lead can be varied along the worm shaft. This is called dual lead worm gear, and is used to eliminate play in the main worm gear of hobbing machines. The pitch diameters of worm modules are equal. The same principle applies to their pitch diameters. Generally, the lead angle increases as the number of threads decreases. Hence, the larger the lead angle, the less self-locking it becomes.

worm gears in fishing reels

Fishing reels usually include worm shafts as a part of the construction. Worm shafts in fishing reels allow for uniform worm winding. The worm shaft is attached to a bearing on the rear wall of the reel unit through a hole. The worm shaft’s front end is supported by a concave hole in the front of the reel unit. A conventional fishing reel may also have a worm shaft attached to the sidewall.

The gear support portion 29 supports the rear end of the pinion gear 12. It is a thick rib that protrudes from the lid portion 2 b. It is mounted on a bushing 14 b, which has a through hole through which the worm shaft 20 passes. This worm gear supports the worm. There are two types of worm gears available for fishing reels. The two types of worm gears may have different number of teeth or they may be the same.

Typical worm shafts are made of stainless steel. Stainless steel worm shafts are especially corrosion-resistant and durable. Worm shafts are used on spinning reels, spin-casting reels, and in many electrical tools. A worm shaft can be reversible, but it is not entirely reliable. There are numerous benefits of worm shafts in fishing reels. These fishing reels also feature a line winder or level winder.

worm gears in electrical tools

Worms have different tooth shapes that can help increase the load carrying capacity of a worm gear. Different tooth shapes can be used with circular or secondary curve cross sections. The pitch point of the cross section is the boundary for this type of mesh. The mesh can be either positive or negative depending on the desired torque. Worm teeth can also be inspected by measuring them over pins. In many cases, the lead thickness of a worm can be adjusted using a gear tooth caliper.

The worm shaft is fixed to the lower case section 8 via a rubber bush 13. The worm wheel 3 is attached to the joint shaft 12. The worm 2 is coaxially attached to the shaft end section 12a. This joint shaft connects to a swing arm and rotates the worm wheel 3.

The backlash of a worm gear may be increased if the worm is not mounted properly. To fix the problem, manufacturers have developed duplex worm gears, which are suitable for small backlash applications. Duplex worm gears utilize different leads on each tooth face for continuous change in tooth thickness. In this way, the center distance of the worm gear can be adjusted without changing the worm’s design.

worm gears in engines

Using worm shafts in engines has a few benefits. First of all, worm gears are quiet. The gear and worm face move in opposite directions so the energy transferred is linear. Worm gears are popular in applications where torque is important, such as elevators and lifts. Worm gears also have the advantage of being made from soft materials, making them easy to lubricate and to use in applications where noise is a concern.

Lubricants are necessary for worm gears. The viscosity of lubricants determines whether the worm is able to touch the gear or wheel. Common lubricants are ISO 680 and 460, but higher viscosity oil is not uncommon. It is essential to use the right lubricants for worm gears, since they cannot be lubricated indefinitely.

Worm gears are not recommended for engines due to their limited performance. The worm gear’s spiral motion causes a significant reduction in space, but this requires a high amount of lubrication. Worm gears are susceptible to breaking down because of the stress placed on them. Moreover, their limited speed can cause significant damage to the gearbox, so careful maintenance is essential. To make sure worm gears remain in top condition, you should inspect and clean them regularly.

Methods for manufacturing worm shafts

A novel approach to manufacturing worm shafts and gearboxes is provided by the methods of the present invention. Aspects of the technique involve manufacturing the worm shaft from a common worm shaft blank having a defined outer diameter and axial pitch. The worm shaft blank is then adapted to the desired gear ratio, resulting in a gearbox family with multiple gear ratios. The preferred method for manufacturing worm shafts and gearboxes is outlined below.

A worm shaft assembly process may involve establishing an axial pitch for a given frame size and reduction ratio. A single worm shaft blank typically has an outer diameter of 100 millimeters, which is the measurement of the worm gear set’s center distance. Upon completion of the assembly process, the worm shaft has the desired axial pitch. Methods for manufacturing worm shafts include the following:

For the design of the worm gear, a high degree of conformity is required. Worm gears are classified as a screw pair in the lower pairs. Worm gears have high relative sliding, which is advantageous when comparing them to other types of gears. Worm gears require good surface finish and rigid positioning. Worm gear lubrication usually comprises surface active additives such as silica or phosphor-bronze. Worm gear lubricants are often mixed. The lubricant film that forms on the gear teeth has little impact on wear and is generally a good lubricant.

in Antalya Turkey sales price shop near me near me shop factory supplier Industrial Worm Gear Reducer with Hollow Shaft manufacturer best Cost Custom Cheap wholesaler

Our merchandise are produced by modern day computerized machinery and gear. EPG will usually adhere to it enterprise spirit of getting practical, modern, efficient and excellent to make the best worldwide transmission drive. Meanwhile, our goods are manufactured in accordance to substantial high quality standards, and complying with the global innovative regular criteria. EPTT worm EPT EPTT with hollow shaft

1 time period Product functions

1 period1 interval Flange-mounted with hollow shaft comma foot-mounted with hollow shaft comma and optional torque arm and other EPTT components interval

1 period2 period Big energy comma EPTT support lifestyle period of time

one period3 period of time To be blended with different motors for larger EPTT ratio interval

one period4 interval Carburized EPTs are sturdy and extremely accurate interval

one period5 period EPT overload capability and minimal sounds

| Input EPTT | period12 – two hundred Kw |

| Ratio | 5 period36-17550 |

| Output torque | up to 50000 N period M |

1 period3 time period They are commonly utilised in different reduced-pace EPTTs comma which are EPTT fundamental parts of mechanical EPTT period of time

2 time period EPTnical parameters

| EPT content | Forged iron |

| EPT hardness | HBS90-240 |

| EPT materials colon | 20CrMnTi |

| Surface area hardnesss of EPT | EPTC58 deg-sixty two deg |

| EPT main hardness | EPTC33 deg-forty deg |

| Input solOutput shaft materials | 40CrMnTi |

| Enter solOutput shaft hardness | HBS241 deg-286 deg |

| Shaft at oil seal postion hardness | EPTC48 deg -fifty five deg |

| Machining precision of EPTs content | Exact grinding 6-five quality |

| Heat treatment method | tempering comma cementing comma quenching and many others |

| Effectiveness | up to 90 percnt |

| Sounds lparMax rpar | 60-68dB |

| Device product | Foot mounted commaflange mounted commahollow shaft mounted |

| Enter strategy | flange enter commainline enter commashaft enter |

| Vibration | le 20um |

| Backlash | le 20Arcmin |

| EPTT brands | NSK commaC ampU and so forth |

| Oil seal brands | NAK commaSKF and many others |

| Lubricant | VG680 |

| EPT | IP55 comma F class |

| EPT shaft | 40Cr comma Tempering comma cementing commaquenching and many others period of time |

three periodApplications

HangEPT XG EPTT EPTT EPTT are commonly utilised in colon

Ceramic Industry

Glass Industry

Foodstuff Market

EPTlurgy Sector

Beer amp Drink Industry

EPT and dyeing Business

EPT Market

Warehouse Logoistics Sector

EPT functioning EPTTry

environmental security gear Business

Leather-based Sector

Pharmacy Industry

4 periodOur Solutions

4 period1 periodWe offer 12 months Guarantee period

4 period2 period We have hundreds of EPTT EPTTs time period From Enter EPTT period06KW to 200KW comma Ratio one period3-289 period74 comma Output speed -1095rpm and Output torque 1 period4-62800Nm interval time period periodThey can meet up with your all distinct requirements for different EPTT time period

four period3 interval We provide E-catalog or Paper catalog commaso you can pick the model simply according to your needs

4 period4 periodYou are welcome to pay a visit to our manufacturing facility to examine our merchandise commawe can assist you to guide the resort or ticket

5 periodEPTT Info

5 period1 periodOur EPTT colon

The Predecessor for ZheJiang EPT Generate CO period of time commaLtd lparoriginally known as HangEPT XiHu (West EPT) Dis.ngguang EPTT EPTTry CO interval commaLtd rpar Point out-owned armed forces mould EPTTrpriese which estabEPTTd in 1965 period of time

EPT is located in HangEPT commaEPTT and the manufacturing unit handles an region of about 25000 square meters time period

Generation Ability colonmore than 50 % a million sets of speed EPTT for each year period of time

five period2 periodOur Men and women colon

The organization has a strong technological force period It has far more than 400 employees at existing comma incXiHu (West EPT) Dis.Hu (West EPT) Dis. far more than 40 engineering specialists and 10 professionals and senior engineers enEPTTing EPTT allowances of the Condition Council time period

five period3 period of time Our Certificates colon

Passed quot ISO 9001 Worldwide EPTT Technique Certificate quot comma quotInternational EPTT Credit history AAA in addition additionally Ceritifacte quot comma quot Swiss SGS Certification quot comma Iconic Model in EPTT EPTT Market quot comma quotFamous Manufacturer of ZheJiang Province quot comma quotNon-public Scientific and EPTnological EPTTrprise in ZheJiang Province quot comma quotNational EPT and EPTT-tech EPTTrprise quot comma quotTOP 50 in EPTT EPT Business quot quot2011 HangEPT EPT and EPTnological R ampD CEPTTr quot and so on interval

six period FAQ

Q colonAre you a investing firm or company quest

A colon The predecessor of HangEPT XG-EPTT EPTTry Co time period comma Ltd is State-owned XiHu (West EPT) Dis.ngguanggong Mould Factory comma a condition-owned armed forces EPTT EPTTrprise estabEPTTd in 1965 time period It completed reform in 2002 interval Given that reform comma the firm has deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ed swiftly period of time It took the guide in passing ISO9001 Global EPTT System Certification and Global EPTT Credit rating AAA additionally plus Certificate in 2004 comma and Swiss SGS Certificate in 2009 time period It has won this sort of titles as quotIconic Model in EPTT EPTT Sector quot comma quotFamous Manufacturer of ZheJiang Province quot comma quotNon-general public Scientific and EPTnological EPTTrprise in ZheJiang Province quot comma quotNational EPT and EPTT-tech EPTTrprise quot comma and quotTope fifty in EPTT EPT Business quot successively

Q colonWhere do you base quest

A colon We are in HangEPT commaZheJiang commaEPTT interval We have two factories commaEPTT factory is in XiHu (West EPT) Dis.hu (West EPT) Dis. district commaHangEPT commaEPTT and the previous one is in CHangEPT District commaHangEPT commaEPTT period

Q colonWhat sorts of EPTT can you generate for us quest

A colonMain items of our business colon JWB-X series mechanical repeatedly variable EPTT comma RV collection worm EPT EPTT comma B solJXJ cycloidal pin EPT pace EPTT comma NCJ collection EPT EPTT comma and R comma S comma K comma and F sequence helical-tooth EPTT comma far more than a single hundred types and hundreds of requirements interval

Q colonWhat are the software of the EPTT quest

A colonEPT are commonly utilized in ceramic comma EPT comma foodstuff comma metallurgy comma beer amp consume comma printing and dyeing comma textile comma petrochemical engineering comma warehouse EPT comma wooden-operating EPTT comma environmental protection gear comma printing and EPTT comma pharmacy comma and leather period EPT are marketed in some international locations and regions comma this kind of as Europe comma The united states comma and SouthEPT Asia comma and it possesses dozens of distributors and right after-sale support agents interval

Q colonWhat is the content you use quest

A colon EPTT situation lpar For the RV sequence worm EPTT commamodel RV030-105 rpar

Cast iron lparFor the RV series worm EPTT comma model RV110-150 comma For the NCJ solF solR solS solK collection helical EPT EPTT rpar

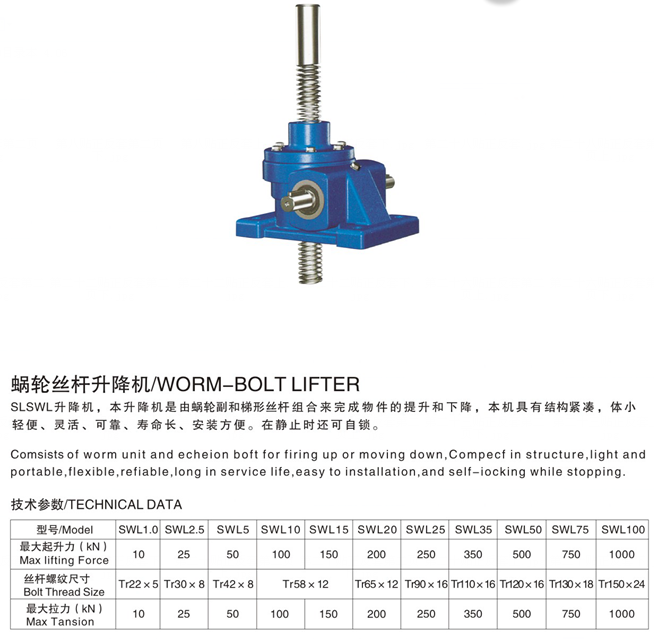

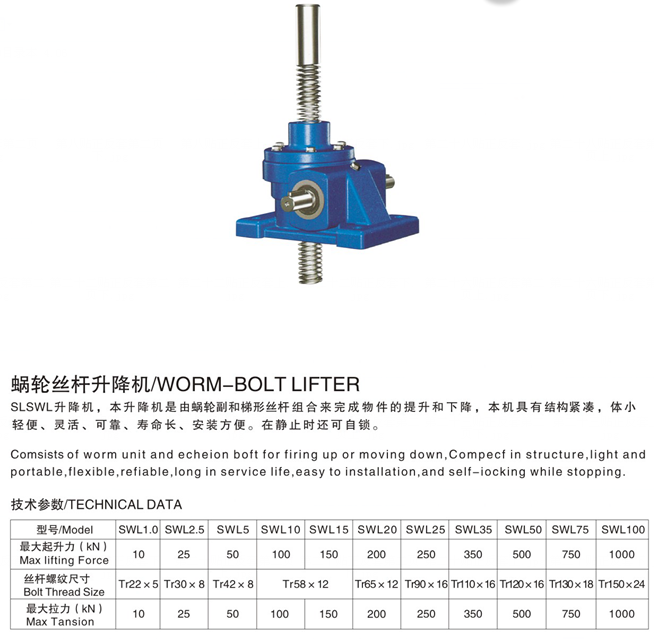

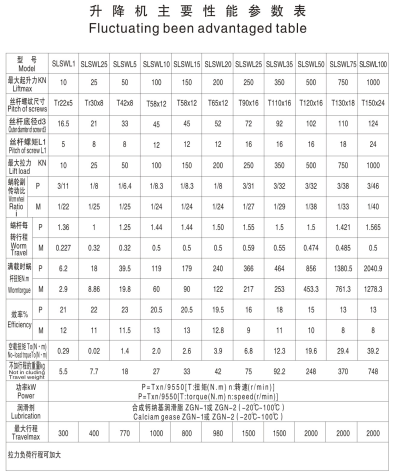

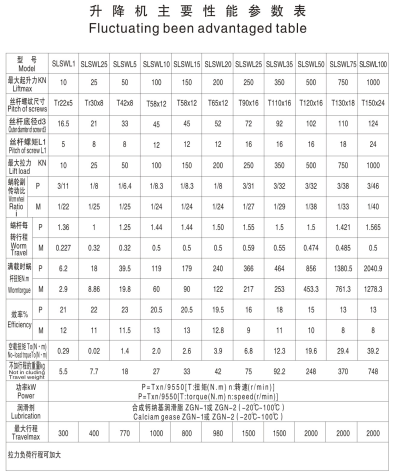

China manufacturer & factory supplier for Swl in Kakinada India worm bolt lifter jack screw adjuster speed variator parallel shaft helical gearbox swl bevel gear screw jack worm gear With high quality best price & service

ISO 9001:2015 accredited producer and distributor of roller chains. Sorts of roller chains consist of ASME/ANSI regular chains, attachment chains, corrosion resistant chains, lube-free chains, plastic chains, free of charge-circulation chains, specialty chains and British normal chains. ASME/ANSI normal chains are offered in huge and small pitch, double pitch and leaf designs. Roller chains are utilized in food packaging, forklift vehicles, oilfield drilling, motorcycles, conveyors and power transfer purposes.Getting accrued treasured encounter in cooperating with foreign customers, a specialised supplier of a complete assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Constructing Content Outlets

- Output Torque:

-

Shut up of two yokes with the common joint. Note the slight oozing of grease from the UJ seal finishes, the clump of grease is from inside of the yoke splined shaft location –Travel (outer) yoke has a female (usual spline) hole and “Y” shape finish that is the common joint (UJ) mount. –UJ is a cross shaped casting having roller bearings enclosed with caps at all four factors and is held into the yoke with 4 “C” clips –Internal yoke and generate shaft is yet another yoke welded to the generate end, of the drive shaft. –Pushed shaft and interior yoke is the pushed shaft that rides inside of of the travel shaft and has a yoke welded at the pushed end –UJ another UJ as earlier mentioned

1.8-2430N.M

- Enter Velocity:

-

Principal goods incorporate: manure spreading truck, potato planting/harvesting equipment, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, mix rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its equipment: Plow disc blades, harrowing movie, plough tip and share, cultivator tine, casting elements etc.

750-1500rpm

- Output Pace:

-

.sixty four-350rmp

Structural functions The worm equipment consists of three essential parts : housing, worm and wheel.

- Spot of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Certification:

-

ISO9001-2008

- Equipment material:

-

Low carbon high alloy metal

- Heat treatment method:

-

Carburising, quenching, gear grinding

- Diameter & Length and Lifting Top:

-

Made as request

- Bearing:

-

C&U

- gear precision quality:

-

din 4

Offer Potential

- Offer Potential:

- five hundred Unit/Models for each Thirty day period

Packaging & Supply

- Packaging Information

- Regular exporting package

- Port

- Ningbo Port, Shanghai Port

-

Guide Time

: -

Quantity(Boxes) one – one >1 Est. Time(times) twenty To be negotiated

Online Customization

Swl worm bolt lifter jack screw adjuster pace variator parallel shaft helical gearbox swl bevel gear screw jack worm equipment

Benefit:

SWL Worm-bolt lifter has the attributes of compacted composition, gentle and moveable, versatile, trustworthy, extended service existence, easy to set up, and self-locking even though cease.

Software Industries:

SWL series screw jacks are widely utilized in industries this sort of as metallurgy,mining,hoisting and transportation, electrical power,strength resource, construction and constructing materials,light-weight sector and visitors industry

Packing Information : Standard carton/Pallet/Normal wood case

Shipping and delivery Specifics : 15-30 operating days upon payment

Q1: What details must I tell you to verify the product?

A: Model/Dimension, Transmission Ratio, Shaft instructions & Buy amount.

Q2: What can i do if I don’t know which a single I need?

A: Will not be concerned, Deliver as significantly information as you can, our team will support you discover the proper 1 you are hunting for.

Q3:What is your merchandise warrenty time period?

A:We offer you 1 calendar year warrenty because the vessel departure day remaining China.

If you have yet another question, pls really feel free of charge to get in touch with us.

DIN made in China – replacement parts – in Liverpool United Kingdom ANSI Standard Spiral Bevel Gear Worm Gear with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For much more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

XIHU (WE EPT LAKE) DIS. EPT Chain Group is the mo EPT specialist manufacturer of power transmission in China, manufacturing roller chains, industry sprockets, bike sprockets, casting sprockets, different type of couplings, pulleys, taper bushes, locking products, gears, shafts, CNC precision areas and so on. We have handed ISO9001, ISO14001, TS16949 this sort of top quality and enviroment certification.

DIN ANSI Common Spiral Bevel Equipment Worm Equipment

Gear with straight tooth

Precision Forging

Mould from .5–sixteen

20CrMnTi, 20Cr, 40Cr

Carburization

Large top quality lubrication

| Product name | DIN ANSI Normal Spiral Bevel Gear Worm Gear |

| Materials Available | one. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420 |

| 2. Steel:C45(K1045), C46(K1046),C20 | |

| 3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40) | |

| 4. Bronze: C51000, C52100, C54400, etc | |

| 5. Iron: 1213, 12L14,1215 | |

| six. Aluminum: Al6061, Al6063 | |

| 7.OEM according to your request | |

| Surface area Treatment | Annealing, natural anodization, heat treatment, polishing, nickel plating, chrome plating, znic plating,yellow passivation, gold passivation, satin, Black area painted and many others. |

| Products Available | sprockt chains, pulley, shafts(axles, spline shafts, dart shafts),gears (pinions, wheels gear rack) bearing, bearing seat, bushing, coupling, lock assembly etc. |

| Processing Method | CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly |

| QC : | Technicians self-check in production,closing-verify ahead of package by skilled Good quality inspector |

| Size | Drawings |

| Package deal | Wooden Scenario/Container and pallet, or as per customized specifications |

| Certificate | ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009 |

| Edge | High quality fir EPT Service superior , Superior products,Knowledgeable workers, EPT screening gear |

| Lead Time | 15-25days samples. 30-45days offcial order |

The use of unique gear manufacturer’s (OEM) part numbers or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our business and the detailed replacement elements contained herein are not sponsored, accepted, or created by the OEM.

China manufacturer & factory supplier for Worm in Ogbomosho Nigeria gearbox NMRV130 worm small reducer with 2.2kw gear motor With high quality best price & service

Company & distributor of roller & wire rope end chains. Varieties of chains consist of alloy, high tensile transportation, large take a look at & evidence coil chains. Programs contain log chains, cargo lashings, pipe line handing, tailgates, guard rails & swap chains.In 2000, EPG took the direct in attaining ISO14001 atmosphere administration certification and thereafter handed the inspection of clear production and recycling economy, successful the title of “Zhejiang Eco-friendly Company”.

Overview

Swift Specifics

- Relevant Industries:

-

Production Plant

- Brand name Identify:

-

OEM

- Merchandise NO:

-

SYF

- Model Variety:

-

NMRV

- Merchandise Search phrases:

-

nrv worm gearbox,nrv worm gear pace reducer,nrv worm gear

- Coloration:

-

Blue

- Merchandise identify:

-

Worm Gear Screw Jack

- Substance:

-

Aluminium Alloy

- Application:

-

Equipment Tool

- Bearing:

-

NSK

- Certification:

-

ISO9001

- Ratio:

-

5-a hundred

Packaging & Shipping and delivery

-

Direct Time

: -

Quantity(Items) 1 – 500 >500 Est. Time(days) 20 To be negotiated

On-line Customization

Mounting Dimension

The products are commonly utilized in the creating equipments of all varieties of industries inside and outside the house China. They are the greatest alternatives for nowadays present day services of mechanical lowering travel manage to understand massive twisting distance, big equipment ratio, little sound, higher efficiency and balance.

|

Design: |

NMRV025, 030, 040, 050, 063, 075, 090, 110, 130, 150 |

|

Ratio: |

1:5,7.5,ten,fifteen,twenty,25,thirty,forty,50,60,eighty,a hundred |

|

Coloration: |

Blue, Silver Or On Client Request |

|

Sound: |

minimal noise (<50DB) |

|

Benefit: |

Productive and risk-free running |

|

Content: |

Housing: Die-Solid Aluminum Alloy |

|

Worm Equipment-Bronze 9-4# |

|

|

Worm-20CrMnTi with carburizing and quenching, surface harness is fifty six-62HRC |

|

|

Shaft-chromium metal-45# |

|

|

Packing: |

Carton and Wooden Scenario |

|

Bearing: |

C&U Bearing |

|

Seal: |

NAK SKF |

|

Certificate: |

ISO9001,CE,3C,OEM |

|

Warranty: |

twelve months |

|

Input Electrical power: |

.06kw, .09kw, .12kw, .18kw, .25kw, .37kw, .55kw, .75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

|

Usages: |

Industrial Machine: Foods Stuff, Ceramics,CHEMICAL,Packing,Dyeing, Woodworking,Glass. |

|

IEC Flange: |

56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

|

Lubricant: |

Artificial & Mineral |

Item Deseription

Single Step Worm Gear Reducer.

The reducer which product is 25~ninety created of Aluminum alloy die-casting box,good seeking in look,compact in construction,rust proofing on surface and small volume to save mounting space.

The reducer model of a hundred and ten~a hundred and fifty is made of cast iron which casted with Aluminum mould.It`s good looking and solid, and can be employed by means of the setting of multi-azimuth.

Good radiating characterstic leads safe and trustworthiness,and substantial efficiency for utilizing.

The robust capacity of loading ensure secure transmission,make considerably less vibration and noise.

May differ of connecting framework for power input and torque output satisfy distinct call for-meritsthe design of box outline and the established SHAFT Area Good quality To function effectively and give satisfactory lifestyle, oil seals must have a slender oil movie among the seal lip and mating shaft journal. This situation, known as hydrodynamic lubrication, requirements shaft surfaces that are not flawlessly clean but have microscopic pockets to help maintain the lubAdding a second motor basically is not functional, which makes power take off (PTO) a beneficial aspect in supplying electrical power to secondary functions. To identify their benefit needs a greater comprehension of these programs, their various types, and their numerous applications.ricant film. Though plunge grinding is most extensively employed to end seal journals, the resulting floor is not perfect from this standpoint. Other ending techniques, these kinds of as shot peening and liquid honing, provide a matte-variety finish which is typically more successful than a plungeground surface area. Nevertheless, even these techniques frequently leave raised, sharp corners that separate the resulting microscopic indentations, yet again offering possible starting points for leaks.of foot gap with great versality is apt to a lot of types of mounting.

The NMRV worm gearbox is new era of merchandise by our manufacturing facility on the basis of perfecting WJ series products with compromise of innovative technologies both at residence and overseas.It’s apprearance adopts innovative square box structure.It is outer entire body is created of higher high quality aluminium alloy die casting into forming.It truly is tiny in volume,mild bodyweight,large in radiating effectiveness,massive in output torque,easy in working and reduced sounds.It’s suitbale for all positions.

Strategy for model chosen

Please recognize the adhering to at very first in get to delect the design of RV velocity reducer effectively.

– Loading situation

– Speed scope or ratio in software

– Operating problem and atmosphere

– Set up space

Organization profile

HangZhou EPT Group – one particular of the largest gearbox producer in China – Electromechanical Facilities Co. Ltd

HangZhou EPT Team – one of the largest gearbox maker in China – Electromechanical EMain goods incorporate: manure spreading truck, potato planting/harvesting device, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, merge rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its equipment: Plow disc blades, harrowing film, plough idea and share, cultivator tine, casting components and so on.quipment Co., Ltd.is a gift enterprise integrating growth, design and style, production and income,Primary advertising merchandise incorporate reducer motor,water pump,building machinery and components,bearings,components and electrical gear,plastic goods,Labour security appliance.Our organization often comply with the procedure concept which includes men and women-oriented, innovation as the soul,be ready for threat in times of peace, unremitting……

Application area

Certifications

Comprehensive Photographs

Packing & Delivery

|

Packaging |

|

|

Measurement |

500 (L) * 500 (W) * 400 (D) |

|

Bodyweight |

1.2 T |

|

Packaging Information |

The regular bundle is wood box(Size: L*W*H). If export to european nations around the world,the wooden box will be fumigated.If container is also tigher,we will use pe film for packing or pack it according to customers specific ask for. |

|

Packaging |

|

|

Measurement |

five hundred (L) * five hundred (W) * 400 (D) |

|

Fat |

one.2 T |

|

Packaging Details |

The typical package deal is picket box(Dimension: L*W*H). If export to european international locations,the wooden box will be fumigated.If container is way too tigher,we will use pe film for packing or pack it in accordance to clients particular ask for. |

FAQ

Q1: Are you trading company or company ?

A: We are a producer in ZheJiang China.welcome to our manufacturing unit to have a check out.

Q2: How we decide on designs and specifications?

A:You can email us the series title & code (for example: WJ sequence worm gearbox) as nicely as requirement information, this kind of as motor power, output pace or ratio, provider factor or your software…as significantly information as feasible. If you can offer some photos or drawings, it is better.

Q3: How is your price? Can you provide any low cost?

A: We will give the ideal value we can foundation on your needs and the quantities.

This autumn: How lengthy must I hold out for the opinions following I deliver the enquiry?

A: Inside of twelve several hours.

Q5: What is your merchandise warranty period?

A:We provide one year warranty considering that the vessel departure day left China.

Q6: What industries are your gearboxes currently being utilized?

A:Our gearboxes are extensively utilized to metallurgical products, mining products, automation equipment, foodstuff equipment, packaging tools, tobacco equipment and so on.

Make contact with us

Cell: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Add:No.789 ShenHua Road, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT Team – one of the biggest gearbox maker in China – Electromechanical Amenities Co. Ltd.

PC-Nmrv made in China – replacement parts – in Kumamoto Japan Series 080-130 Worm Gear Reducer with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 different branches. For more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

We commenced our organization from 1995 and now we are the one of the leader manufacturer of power transmission products. It focuses largely on Keyless Locking Products, Timing Belt Pulleys, Roller Chains, Bearing, Jaw Couplings, Gears and EPT components.

These merchandise are made in conformity with the Intercontinental Normal and the expectations adopted in industrialized nations (DIN ANSI BS JIS) with up to knowledge gear, innovative technologies and ideal administration program for high quality manage. It boasts a staff with rich expertise in this business, concentrating on global market place. So the products are of good good quality with aggressive charges.

Our aim : Offering 1st-course products and service to our customers and enterprise partners.

The use of authentic gear manufacturer’s (OEM) portion quantities or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our firm and the shown substitution components contained herein are not sponsored, authorized, or manufactured by the OEM.

DC Cost made in China – replacement parts – in Riyadh Saudi Arabia Worm Gear Motor with 24V 33rpm 6nm with top quality

We – EPG Team the largest gearbox & motors , couplings and gears manufacturing unit in China with 5 diverse branches. For much more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13 571 88828 13858117778 571 88828

General data

- Aluminum die-casting gearbox

- Rolled metal housing design

- Constructed-in EMC factors

- Hall sensor opinions accessible

- Different output shaft extensions are offered

Specifications

| Specifications | MB062FF100-WD0069 |

| No load pace | 33(rpm) |

| Rated voltage | 24(V) |

| Rated velocity | 28(rpm) |

| Rated existing | 2.5(A) |

| Rated torque | six(nm) |

| Peak torque | ten(nm) |

Other gear ratio is avaiable at special manufacturing

Company Profile

- Initially motor division of CMEC HangZhou- China Countrywide Machinery & Tools Imp & Exp HangZhou Co.,Ltd., one of Prime 20 said owned Equipment Team

- Privately owned Ltd company considering that 2000: HangZhou Junhong Automation Technology Co. Ltd.

- Exmek Electrical —Registered Brand Name

- Business: Design and style and manufacture of motion handle goods and parts

- Hugely experienced staff

- UL, CE, RoHS certification

- ISO 9001, ISO 14000

Organization Capabilities

- Present day Motor Design and Manufacture

- Component Established Style and Manufacture

- Magnetic Design and style Computer software-Motorsolver

- Molding

- Shipping and delivery entire world wide

Why Exmek Electrical

- Open for general dialogue and queries

- Time to industry or theatre of operations can be considerably diminished

- Talented group of engineers providing progressive complex options

- A single end “provider” and comprehensive sub-method

- Quality items offered at competitive lower value

- Capacity to ship world wide

- On time shipping

- Instruction at Buyer spots

- Rapidly provider on return and mend outcomes

- Many recurring buyers

Applications:

Use for swimming pool, automotive, semiconductor, chemical & health care, industrial automation, electricity resource, instrument, measuring products, place of work automation, various OEM application.

We are open for general dialogue and queries. Contact us now!

Exmek Electric, your extended-phrase reliable associate.

The use of original equipment manufacturer’s (OEM) part quantities or logos , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our firm and the shown alternative elements contained herein are not sponsored, accredited, or created by the OEM.

Best China manufacturer & factory SWL in Aurangabad India worm lifter gear screw jack power transmission hoist gearbox tricycle speed transmission gearbox small differential gear box With high quality best price

we have obtained the trust of buyers worldwide. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Output Torque:

-

9550

- Input Speed:

-

9550

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Certification:

-

ISO9001-2008

- Lifting Capacity:

-

request

- Lifting Height(mm):

-

customized

- Overall Width(mm):

-

As request

- Gear material:

-

Low carbon high alloy steel

- Heat treatment:

-

Carburising, quenching, gear grinding

- Diameter & Length of Screw:

-

Maintenance This kind of gear reducer is provided with a permanent lubrication, so it does not need any kind of maintenance.

Designed as request

- Bearing:

-

U&C

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Standard exporting package

- Port

- Ningbo Port, Shanghai Port

Online Customization

Product Description

SWL worm gear screw jack lifter has the features of compacted structure, light and portable, flexible, reliable, long service life, easy to installation, and self-locking while stop.

Certifications

Trade Shows

Packaging & Shipping

Packing Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Related Products

Contact

AT series with tri-lobe tube (triangular) The triangular tube shape is the most used, from lightweight to fairly heavy applications. In the case of applications with high sliding, the R version with Rilsan coating is also available. AL series with two-lobe tubes (lemon).

Slewing can you use a 3 phase vfd on a single phase motor best made in China – replacement parts – in Songkhla Thailand Drive Worm Gear Motor for Solar Tracker with top quality

We – EPG Team the largest worm gearbox, couplings and gears manufacturing facility in China with 5 various branches. For much more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

SC9 slewing drive worm gear for eighteen-32 square meter solar tracker system.

Slewing push motor for one and twin axis solar plant,PV and CSP system.

|

Design |

SC9 |

IP |

IP65 |

|

Model |

Coresun Push |

Available Load Weight |

five hundred-800kg |

|

IP Class |

IP65 |

Output Torque |

854N.m |

|

Tilting Second Torque |

33.9KN.m |

Holding Torque |

38.7KN.m |

|

Mounting Bolts |

M16 |

Electrial Motor |

24VDC |

|

Gear Ratio |

61:1 |

Efficiency |

40% |

Coresun Generate Gear HangZhou Co., Ltd. Slewing drives perform with regular worm technologies, in which the worm on the horizontal shaft acts as the driver for the equipment. The rotation of the horizontal screw turns a gear about an axis perpendicular to the screw axis. This mix reduces the speed of the pushed member and also multiplies its torque rising it proportionally as the pace decreases. The pace ratio of shafts depends on the relation of the amount of threads on the worm to the amount of enamel in the worm wheel or equipment.

Solar heliostat trac ept program is a mechanical and digital manage device technique which optimizes the use of daylight to improve photoelectric conversion effectiveness in the approach of photothermal and photovoltaic electrical power technology. It mainly involves photovoltaic apps and photothermal apps.

Coresun Travel has extensive expertise in making and building personalized options for PV (Photovoltaic) and CST (Centralized Solar Thermal Vitality) for one- and dual-axis photo voltaic tracker drives. As a expert solar driver company, we have wealthy manufacturing and R & D capabilities, and can supply customers with total solar trac ept system options. Since of the poor wor ept setting, robust wind and dust storms, the slewing bearing used in this kind of products needs excellent seal, Visual appeal corrosion resistance and weathering, In addition, the precision of slewing bearing is essential to be higher, which is usually unfavorable clearance.under 2 meters. The generally used slewing bearing merchandise are four-position ball slewing bearings underneath 2 meters. This variety of structural bearing has versatile rotation and is extremely ideal for the wor ept situations of the Solar heliostat trac ept system. This kind of slewing ring bearing is a single of the principal products of our company.

Coresun Push Slewing Generate Motor Generation Photo and Application

Coresun Generate processes the metallography detection to check out the content and organization composition of worm shaft,slewing gear and casting housing.

Coresun Push slewing generate gear motor with 24VDC motor is certificated by CE

Contact US

It is sincerely bathroom ept ept to cooperating with you for and offering you the ideal good quality item & support with all of our coronary heart!

/ The use of first products manufacturer’s (OEM) part figures or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our firm and the shown substitution parts contained herein are not sponsored, approved, or made by the OEM. /