Product Description

Spline Round Key Way Pin Threaded CZPT Hollow Through Hole Flat D Shape Knurling Spur Helical Worm Transmission Drive Auto Parts Gear Pinion Gearbox Axis Shaft

Features

1. High precision gear shaft for smooth, quiet operation.

2. Flexible for custom-made requests.

3. Stable transmission, low impact, vibration, and noise.

4. Heavy Load capability, more compact, but less complex.

Product Description

| Products | Spur Gear, Helical Gear, Herringbone Gear, Spiral Bevel Gear, Straight Bevel Gear, Worm Gear, Shaft, Pinion |

| Module | M0.3-M10 |

| Precision grade | DIN6, DIN7, DIN8, DIN10 |

| Pressure angle | 14.5 degree, 15 degree, 20 degree |

| Material | Medium Carbon Steel: 35#, 45# Carburizing Steel: 20CrMnTi, 20CrMnMo, 20CrMo Alloy Steel: 40Cr, 35CrMo, 42CrMo, 40CrNiMo Cast Iron: HT250, QT400 Copper, Stainless Steel, Brass, Nylon, POM, and so on |

| Heat treatment | Hardening & Tempering, Surface Quenching, Integral Quenching, Carburizing Quenching, Tempering, Normalizing, Nitriding |

| Surface treatment | Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

| Application | Gearbox and reducer; Precision cutting machines, Lathes machines; Milling machines; Grinder machine; Automated mechanical systems; Automated warehousing systems. Gear hobbing machines, gear shapers, gear shaving machines, gear milling, gear grinding machines and many kinds of gear-related machines. |

| Machining process | Forging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment… |

Detailed Photos

Our Advantages

Related Product

Company Profile

FAQ

Q: How to ship the worm gear to us?

A: It is available by air, sea, or train.

Q: How to pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Gearbox |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample Worm gear with shaft

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

How do drive shafts handle variations in load and vibration during operation?

Drive shafts are designed to handle variations in load and vibration during operation by employing various mechanisms and features. These mechanisms help ensure smooth power transmission, minimize vibrations, and maintain the structural integrity of the drive shaft. Here’s a detailed explanation of how drive shafts handle load and vibration variations:

1. Material Selection and Design:

Drive shafts are typically made from materials with high strength and stiffness, such as steel alloys or composite materials. The material selection and design take into account the anticipated loads and operating conditions of the application. By using appropriate materials and optimizing the design, drive shafts can withstand the expected variations in load without experiencing excessive deflection or deformation.

2. Torque Capacity:

Drive shafts are designed with a specific torque capacity that corresponds to the expected loads. The torque capacity takes into account factors such as the power output of the driving source and the torque requirements of the driven components. By selecting a drive shaft with sufficient torque capacity, variations in load can be accommodated without exceeding the drive shaft’s limits and risking failure or damage.

3. Dynamic Balancing:

During the manufacturing process, drive shafts can undergo dynamic balancing. Imbalances in the drive shaft can result in vibrations during operation. Through the balancing process, weights are strategically added or removed to ensure that the drive shaft spins evenly and minimizes vibrations. Dynamic balancing helps to mitigate the effects of load variations and reduces the potential for excessive vibrations in the drive shaft.

4. Dampers and Vibration Control:

Drive shafts can incorporate dampers or vibration control mechanisms to further minimize vibrations. These devices are typically designed to absorb or dissipate vibrations that may arise from load variations or other factors. Dampers can be in the form of torsional dampers, rubber isolators, or other vibration-absorbing elements strategically placed along the drive shaft. By managing and attenuating vibrations, drive shafts ensure smooth operation and enhance overall system performance.

5. CV Joints:

Constant Velocity (CV) joints are often used in drive shafts to accommodate variations in operating angles and to maintain a constant speed. CV joints allow the drive shaft to transmit power even when the driving and driven components are at different angles. By accommodating variations in operating angles, CV joints help minimize the impact of load variations and reduce potential vibrations that may arise from changes in the driveline geometry.

6. Lubrication and Maintenance:

Proper lubrication and regular maintenance are essential for drive shafts to handle load and vibration variations effectively. Lubrication helps reduce friction between moving parts, minimizing wear and heat generation. Regular maintenance, including inspection and lubrication of joints, ensures that the drive shaft remains in optimal condition, reducing the risk of failure or performance degradation due to load variations.

7. Structural Rigidity:

Drive shafts are designed to have sufficient structural rigidity to resist bending and torsional forces. This rigidity helps maintain the integrity of the drive shaft when subjected to load variations. By minimizing deflection and maintaining structural integrity, the drive shaft can effectively transmit power and handle variations in load without compromising performance or introducing excessive vibrations.

8. Control Systems and Feedback:

In some applications, drive shafts may be equipped with control systems that actively monitor and adjust parameters such as torque, speed, and vibration. These control systems use sensors and feedback mechanisms to detect variations in load or vibrations and make real-time adjustments to optimize performance. By actively managing load variations and vibrations, drive shafts can adapt to changing operating conditions and maintain smooth operation.

In summary, drive shafts handle variations in load and vibration during operation through careful material selection and design, torque capacity considerations, dynamic balancing, integration of dampers and vibration control mechanisms, utilization of CV joints, proper lubrication and maintenance, structural rigidity, and, in some cases, control systems and feedback mechanisms. By incorporating these features and mechanisms, drive shafts ensure reliable and efficient power transmission while minimizing the impact of load variations and vibrations on overall system performance.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2023-12-13

in Antalya Turkey sales price shop near me near me shop factory supplier Industrial Worm Gear Reducer with Hollow Shaft manufacturer best Cost Custom Cheap wholesaler

Our merchandise are produced by modern day computerized machinery and gear. EPG will usually adhere to it enterprise spirit of getting practical, modern, efficient and excellent to make the best worldwide transmission drive. Meanwhile, our goods are manufactured in accordance to substantial high quality standards, and complying with the global innovative regular criteria. EPTT worm EPT EPTT with hollow shaft

1 time period Product functions

1 period1 interval Flange-mounted with hollow shaft comma foot-mounted with hollow shaft comma and optional torque arm and other EPTT components interval

1 period2 period Big energy comma EPTT support lifestyle period of time

one period3 period of time To be blended with different motors for larger EPTT ratio interval

one period4 interval Carburized EPTs are sturdy and extremely accurate interval

one period5 period EPT overload capability and minimal sounds

| Input EPTT | period12 – two hundred Kw |

| Ratio | 5 period36-17550 |

| Output torque | up to 50000 N period M |

1 period3 time period They are commonly utilised in different reduced-pace EPTTs comma which are EPTT fundamental parts of mechanical EPTT period of time

2 time period EPTnical parameters

| EPT content | Forged iron |

| EPT hardness | HBS90-240 |

| EPT materials colon | 20CrMnTi |

| Surface area hardnesss of EPT | EPTC58 deg-sixty two deg |

| EPT main hardness | EPTC33 deg-forty deg |

| Input solOutput shaft materials | 40CrMnTi |

| Enter solOutput shaft hardness | HBS241 deg-286 deg |

| Shaft at oil seal postion hardness | EPTC48 deg -fifty five deg |

| Machining precision of EPTs content | Exact grinding 6-five quality |

| Heat treatment method | tempering comma cementing comma quenching and many others |

| Effectiveness | up to 90 percnt |

| Sounds lparMax rpar | 60-68dB |

| Device product | Foot mounted commaflange mounted commahollow shaft mounted |

| Enter strategy | flange enter commainline enter commashaft enter |

| Vibration | le 20um |

| Backlash | le 20Arcmin |

| EPTT brands | NSK commaC ampU and so forth |

| Oil seal brands | NAK commaSKF and many others |

| Lubricant | VG680 |

| EPT | IP55 comma F class |

| EPT shaft | 40Cr comma Tempering comma cementing commaquenching and many others period of time |

three periodApplications

HangEPT XG EPTT EPTT EPTT are commonly utilised in colon

Ceramic Industry

Glass Industry

Foodstuff Market

EPTlurgy Sector

Beer amp Drink Industry

EPT and dyeing Business

EPT Market

Warehouse Logoistics Sector

EPT functioning EPTTry

environmental security gear Business

Leather-based Sector

Pharmacy Industry

4 periodOur Solutions

4 period1 periodWe offer 12 months Guarantee period

4 period2 period We have hundreds of EPTT EPTTs time period From Enter EPTT period06KW to 200KW comma Ratio one period3-289 period74 comma Output speed -1095rpm and Output torque 1 period4-62800Nm interval time period periodThey can meet up with your all distinct requirements for different EPTT time period

four period3 interval We provide E-catalog or Paper catalog commaso you can pick the model simply according to your needs

4 period4 periodYou are welcome to pay a visit to our manufacturing facility to examine our merchandise commawe can assist you to guide the resort or ticket

5 periodEPTT Info

5 period1 periodOur EPTT colon

The Predecessor for ZheJiang EPT Generate CO period of time commaLtd lparoriginally known as HangEPT XiHu (West EPT) Dis.ngguang EPTT EPTTry CO interval commaLtd rpar Point out-owned armed forces mould EPTTrpriese which estabEPTTd in 1965 period of time

EPT is located in HangEPT commaEPTT and the manufacturing unit handles an region of about 25000 square meters time period

Generation Ability colonmore than 50 % a million sets of speed EPTT for each year period of time

five period2 periodOur Men and women colon

The organization has a strong technological force period It has far more than 400 employees at existing comma incXiHu (West EPT) Dis.Hu (West EPT) Dis. far more than 40 engineering specialists and 10 professionals and senior engineers enEPTTing EPTT allowances of the Condition Council time period

five period3 period of time Our Certificates colon

Passed quot ISO 9001 Worldwide EPTT Technique Certificate quot comma quotInternational EPTT Credit history AAA in addition additionally Ceritifacte quot comma quot Swiss SGS Certification quot comma Iconic Model in EPTT EPTT Market quot comma quotFamous Manufacturer of ZheJiang Province quot comma quotNon-public Scientific and EPTnological EPTTrprise in ZheJiang Province quot comma quotNational EPT and EPTT-tech EPTTrprise quot comma quotTOP 50 in EPTT EPT Business quot quot2011 HangEPT EPT and EPTnological R ampD CEPTTr quot and so on interval

six period FAQ

Q colonAre you a investing firm or company quest

A colon The predecessor of HangEPT XG-EPTT EPTTry Co time period comma Ltd is State-owned XiHu (West EPT) Dis.ngguanggong Mould Factory comma a condition-owned armed forces EPTT EPTTrprise estabEPTTd in 1965 time period It completed reform in 2002 interval Given that reform comma the firm has deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ed swiftly period of time It took the guide in passing ISO9001 Global EPTT System Certification and Global EPTT Credit rating AAA additionally plus Certificate in 2004 comma and Swiss SGS Certificate in 2009 time period It has won this sort of titles as quotIconic Model in EPTT EPTT Sector quot comma quotFamous Manufacturer of ZheJiang Province quot comma quotNon-general public Scientific and EPTnological EPTTrprise in ZheJiang Province quot comma quotNational EPT and EPTT-tech EPTTrprise quot comma and quotTope fifty in EPTT EPT Business quot successively

Q colonWhere do you base quest

A colon We are in HangEPT commaZheJiang commaEPTT interval We have two factories commaEPTT factory is in XiHu (West EPT) Dis.hu (West EPT) Dis. district commaHangEPT commaEPTT and the previous one is in CHangEPT District commaHangEPT commaEPTT period

Q colonWhat sorts of EPTT can you generate for us quest

A colonMain items of our business colon JWB-X series mechanical repeatedly variable EPTT comma RV collection worm EPT EPTT comma B solJXJ cycloidal pin EPT pace EPTT comma NCJ collection EPT EPTT comma and R comma S comma K comma and F sequence helical-tooth EPTT comma far more than a single hundred types and hundreds of requirements interval

Q colonWhat are the software of the EPTT quest

A colonEPT are commonly utilized in ceramic comma EPT comma foodstuff comma metallurgy comma beer amp consume comma printing and dyeing comma textile comma petrochemical engineering comma warehouse EPT comma wooden-operating EPTT comma environmental protection gear comma printing and EPTT comma pharmacy comma and leather period EPT are marketed in some international locations and regions comma this kind of as Europe comma The united states comma and SouthEPT Asia comma and it possesses dozens of distributors and right after-sale support agents interval

Q colonWhat is the content you use quest

A colon EPTT situation lpar For the RV sequence worm EPTT commamodel RV030-105 rpar

Cast iron lparFor the RV series worm EPTT comma model RV110-150 comma For the NCJ solF solR solS solK collection helical EPT EPTT rpar

China manufacturer & factory supplier for Swl in Kakinada India worm bolt lifter jack screw adjuster speed variator parallel shaft helical gearbox swl bevel gear screw jack worm gear With high quality best price & service

ISO 9001:2015 accredited producer and distributor of roller chains. Sorts of roller chains consist of ASME/ANSI regular chains, attachment chains, corrosion resistant chains, lube-free chains, plastic chains, free of charge-circulation chains, specialty chains and British normal chains. ASME/ANSI normal chains are offered in huge and small pitch, double pitch and leaf designs. Roller chains are utilized in food packaging, forklift vehicles, oilfield drilling, motorcycles, conveyors and power transfer purposes.Getting accrued treasured encounter in cooperating with foreign customers, a specialised supplier of a complete assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Constructing Content Outlets

- Output Torque:

-

Shut up of two yokes with the common joint. Note the slight oozing of grease from the UJ seal finishes, the clump of grease is from inside of the yoke splined shaft location –Travel (outer) yoke has a female (usual spline) hole and “Y” shape finish that is the common joint (UJ) mount. –UJ is a cross shaped casting having roller bearings enclosed with caps at all four factors and is held into the yoke with 4 “C” clips –Internal yoke and generate shaft is yet another yoke welded to the generate end, of the drive shaft. –Pushed shaft and interior yoke is the pushed shaft that rides inside of of the travel shaft and has a yoke welded at the pushed end –UJ another UJ as earlier mentioned

1.8-2430N.M

- Enter Velocity:

-

Principal goods incorporate: manure spreading truck, potato planting/harvesting equipment, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, mix rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its equipment: Plow disc blades, harrowing movie, plough tip and share, cultivator tine, casting elements etc.

750-1500rpm

- Output Pace:

-

.sixty four-350rmp

Structural functions The worm equipment consists of three essential parts : housing, worm and wheel.

- Spot of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Certification:

-

ISO9001-2008

- Equipment material:

-

Low carbon high alloy metal

- Heat treatment method:

-

Carburising, quenching, gear grinding

- Diameter & Length and Lifting Top:

-

Made as request

- Bearing:

-

C&U

- gear precision quality:

-

din 4

Offer Potential

- Offer Potential:

- five hundred Unit/Models for each Thirty day period

Packaging & Supply

- Packaging Information

- Regular exporting package

- Port

- Ningbo Port, Shanghai Port

-

Guide Time

: -

Quantity(Boxes) one – one >1 Est. Time(times) twenty To be negotiated

Online Customization

Swl worm bolt lifter jack screw adjuster pace variator parallel shaft helical gearbox swl bevel gear screw jack worm equipment

Benefit:

SWL Worm-bolt lifter has the attributes of compacted composition, gentle and moveable, versatile, trustworthy, extended service existence, easy to set up, and self-locking even though cease.

Software Industries:

SWL series screw jacks are widely utilized in industries this sort of as metallurgy,mining,hoisting and transportation, electrical power,strength resource, construction and constructing materials,light-weight sector and visitors industry

Packing Information : Standard carton/Pallet/Normal wood case

Shipping and delivery Specifics : 15-30 operating days upon payment

Q1: What details must I tell you to verify the product?

A: Model/Dimension, Transmission Ratio, Shaft instructions & Buy amount.

Q2: What can i do if I don’t know which a single I need?

A: Will not be concerned, Deliver as significantly information as you can, our team will support you discover the proper 1 you are hunting for.

Q3:What is your merchandise warrenty time period?

A:We offer you 1 calendar year warrenty because the vessel departure day remaining China.

If you have yet another question, pls really feel free of charge to get in touch with us.

High qualtiy best price SMR Shaft Mounted helical speed reducer worm gearbox 40 bevel gear box shaft drive unit txt shaft mounted gear speed reducer supplier factory manufacturer & exporter in China

EPG was awarded with “famous product of Zhejiang Province” and “famous brand of Zhejiang Province”.

Overview

Quick Details

Applicable Industries: :

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, txt shaft mounted gear speed reducer

Gearing Arrangement: :

Helical

Output Torque: :

max 8000NM

Input Speed: :

1440

Output Speed: :

72, 110, 288

Place of Origin:Zhejiang, China Brand Name: :

OEM

Model Number: :

SMR

Rated Power: :

2.68~134.2

color of Shaft Mounted speed reducer: :

green blue gray

Supply Ability

Supply Ability: : 5000 Piece/Pieces per Month

Packaging & Delivery

Packaging Details: standard export packing and wood pallets packing Port: Shanghai or Ningbo Lead Time : :

| Quantity(Pieces) | 1 – 5000 | >5000 |

| Est. Time(days) | 30 | To be negotiated |

Online Customization

Product Description

Product Description

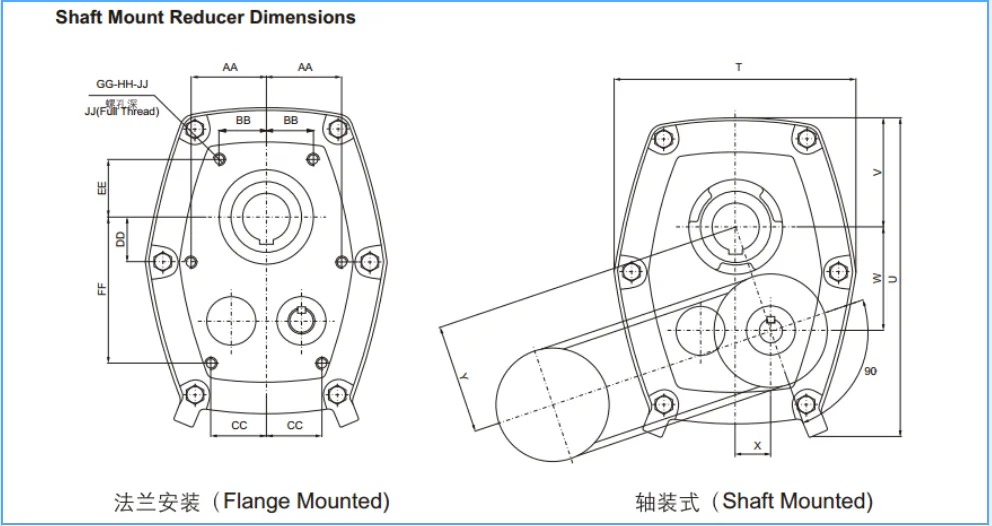

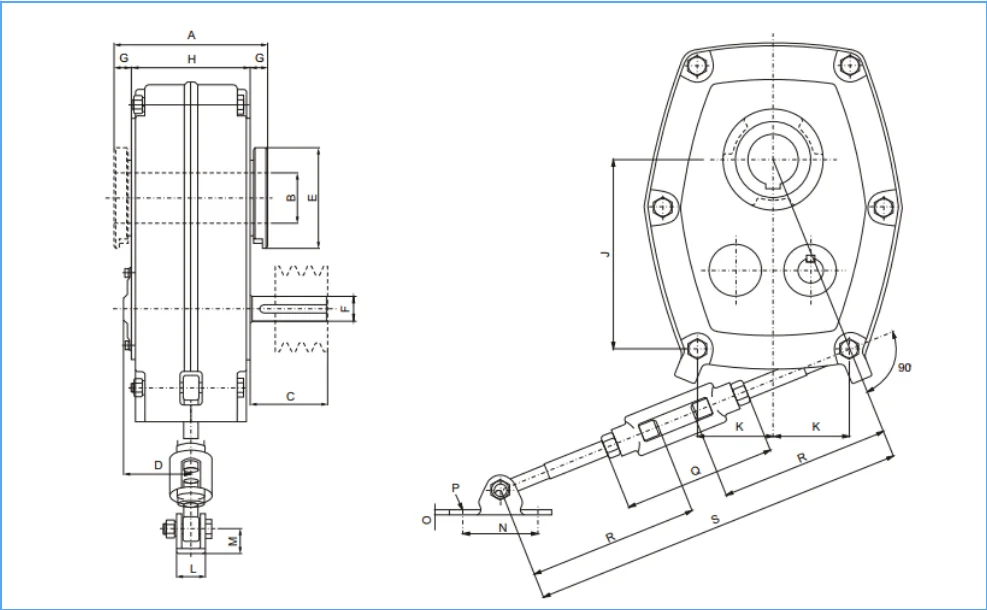

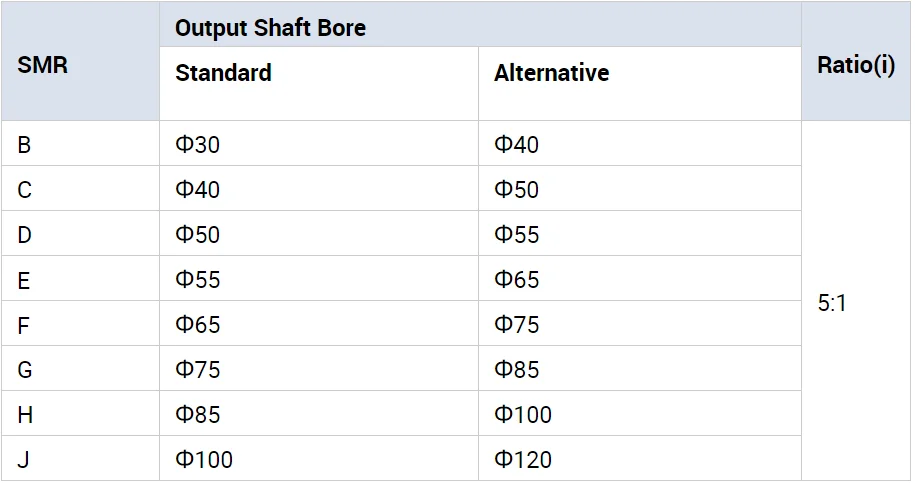

SMR Metric Series

Sizae: B-J

Ratio: 5:1, 13:1, 20:1

Maximum Output Torque: 8000 Nm

SMR Shafted mounted gear speed reducer:

1) Shafted mounted gear unit for conveyer systems

2) All gears are heat treated and fixed to achieve low noise and high output

3) Mounting dimensions are interchangeable with Fene

Product Paramenters

Product Paramenters

Related Products

RelaFURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS’ DRAWINGS.ted Products

Product packaging

Product pacOne aspect of our application consulting is that we have been collecting and combining the experience in chain and sprocket applications in various areas for decades. This is particularly interesting for us whenever customers approach us with some exceeding and challenging requirements.kaging

FAQ

FAQ

Q: Are you trading company or manufacturer ?

A: HZPT group consists in 3 factories and 2 abroad sales cooperations.we are making vacuum pumps,air compressors and gearboxes.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 30-45 days. The time may vary depending on the product and the level of customization. For standard products,

the payment is: 30% T/T in advance ,balance before shippment.,for customized products,50% downpayment is requested normally.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with detail size, material and further specifications;when you place orders,pleasure contact us in advance to communicate all details

36mm worm shaft factory China in Cagayan de Oro City Philippines Brushless Gear Motor for Medical Device with top quality

We – EPG Group the biggest gearbox & motors , couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

Product descripion:

36mm Brushless Gear Motor for Medical Device (FXD36YBL-PG)

Our FXD36YBL-PG Series bldc motor have lots of advantages as below:

1.Nema 14 Brushless dc gear motor

2.Model Number: FXD36YBL-PG-001

3.Phase: 3 Phase

4.Lead Wire(No.): 8 wires

5.Shape: Rounded

6.Motor OD: 36mm(1.417inch)

7.Speed:0-1000 rpm adjusted

8.Applications: Use for Robots bldc motor, electronic automatic equipment bldc motor, medical instrument BLDC motor, advertisementing instrument bldc motor, audio equipment bldc motor, advertising lamp box. Cnc brushless dc motor.

Gemeral info.

| Model No: FXD36YBL -1216-001 | Type: Brushless dc motor |

| Widing type: Star/Delta | Hall Effect angle: 120 degree electric angle |

| Nuber of the phase: 3-Phase | Shaft runout: 0.571mm |

| Insulation class: Class B | Ip class: Ip40 |

| Dielectric Strength: 500VDC for one minite | Insulation resistance: 100MΩmin 500VDC |

Electric Connection:

| Lead No. | Lead Color | Lead Gauge | Function | Description |

| 1 | Red | UL3266/26AWG | VCC | SUPPLY VOLTAGE FOR HALL SENSORS |

| 2 | Black | GND | GROUND FOR HALL SENSORS | |

| 3 | Yellow | HALL A | SINGLE OF HALL A | |

| 4 | Green | HALL B | SINGLE OF HALL B | |

| 5 | Blue | HALL C | SINGLE OF HALL C | |

| 1 | Yellow | UL3266/20AWG | PHASE U | MOTOR PHASE U |

| 2 | Green | PHASE V | MOTOR PHASE V | |

| 3 | Blue | PHASE W | MOTOR PHASE W |

Dimensions diagram:

Electrical specification

| Model (FXD36YBL-) |

voltage |

Rated speed |

Rated torque |

Rated power |

Ratio | speed from gear | torque from gear | stall torque | Mass | Body length |

| VDC | rpm | N.m | w | rpm | N.m | N.m | g | mm | ||

| 1216-PG28-001 | 12 | 3000 | 0.051 | 16 | 28.5:1 | 115 | 1.1 | 3.0 | 500 | 107 |

| 2430-PG20-002 | 24 | 3000 | 0.1 | 30 | 28.5:1 | 115 | 2.0 | 4.0 | 850 | 149 |

Note: If you want different specification,we can product brushless dc motor as your special requirements.

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.